Printer

A printing machine and machine body technology, which is applied in the direction of printing machines, printing, general parts of printing machinery, etc., can solve the problems of surface shrinkage deformation, large energy consumption, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

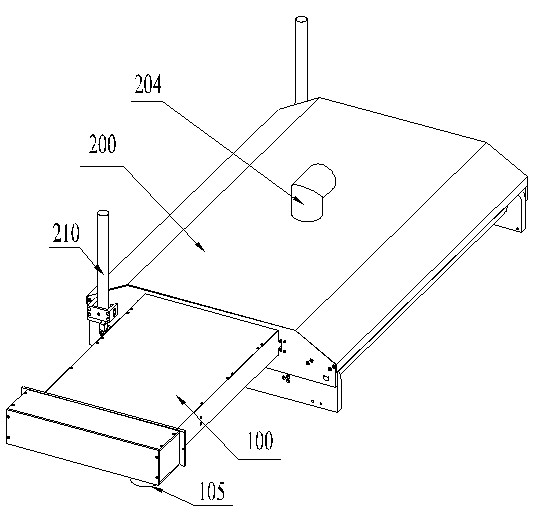

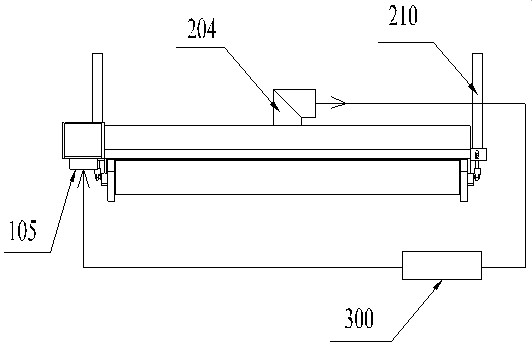

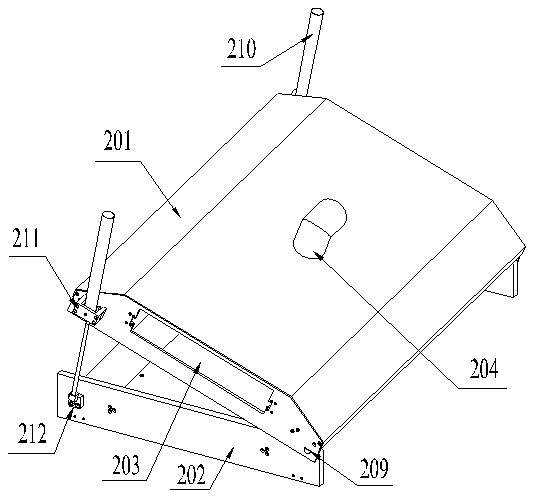

[0023] refer to Figure 1 to Figure 5 , an embodiment of the printing machine of the present invention is proposed, mainly including the printing machine body, and also includes a radiation dryer, the radiation dryer includes a box device 200 and a radiation device embedded in the box device 200 for generating radiation 100. The radiation device 100 includes a box body, a radiation tube 101 evenly arranged in the box body, a transmitter installed in the radiation tube 101 that can generate electromagnetic waves with thermal effects, a drive circuit and a power supply connected to the radiation tube 101, and a box body. The end face is connected with a blowing pipe 105 for passing through the flame retardant gas and a device connected with the blowing pipe 105 for supplying the flame retardant gas. The emitting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com