Manufacturing method of array substrate, array substrate and liquid crystal display

A technology of an array substrate and a manufacturing method, which is applied in the field of liquid crystal displays, can solve the problems of poor TFT-LCD picture quality, movement, and poor friction lines, and achieve the effects of reducing the probability of failure, simplifying the process flow, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

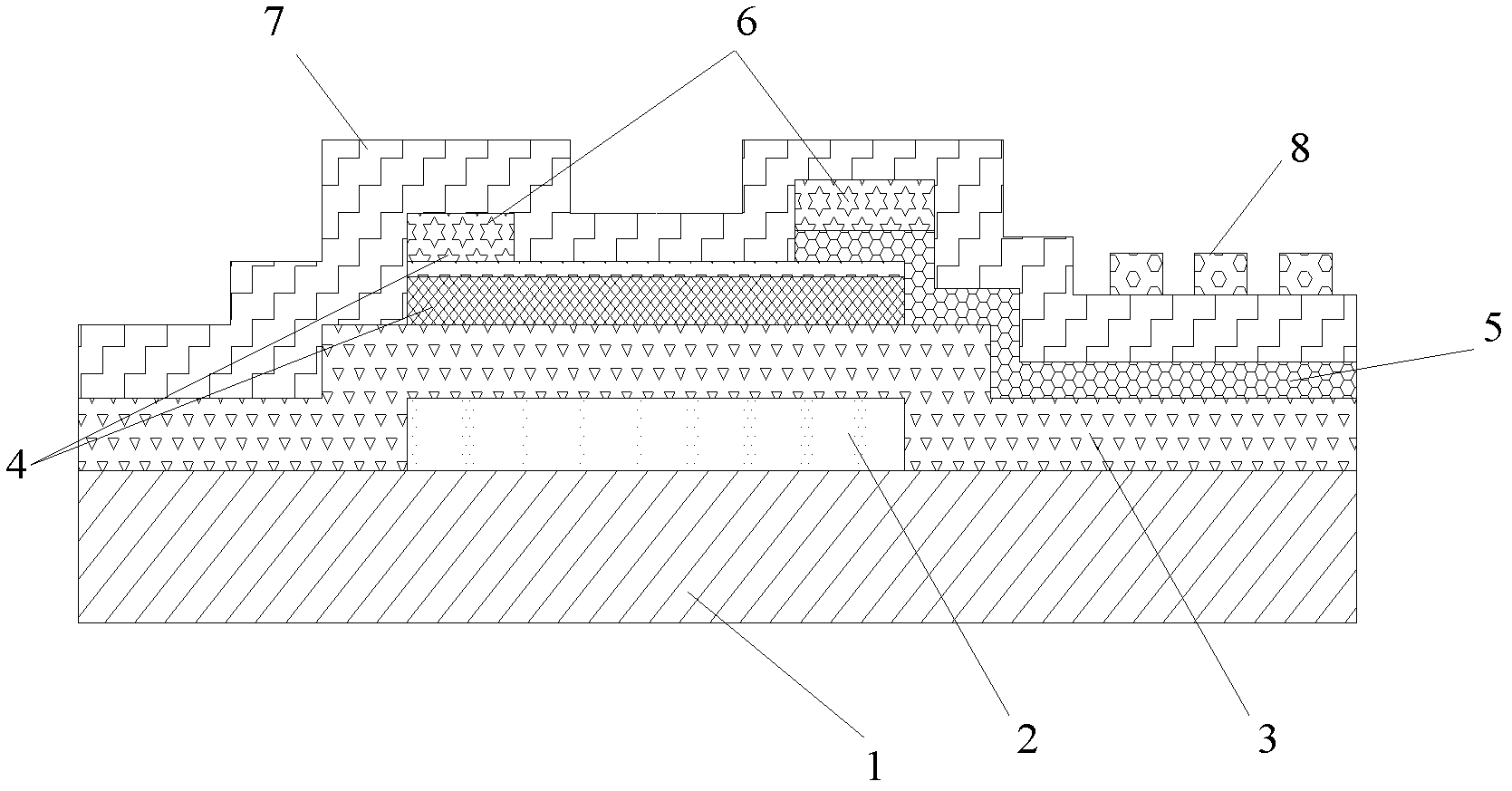

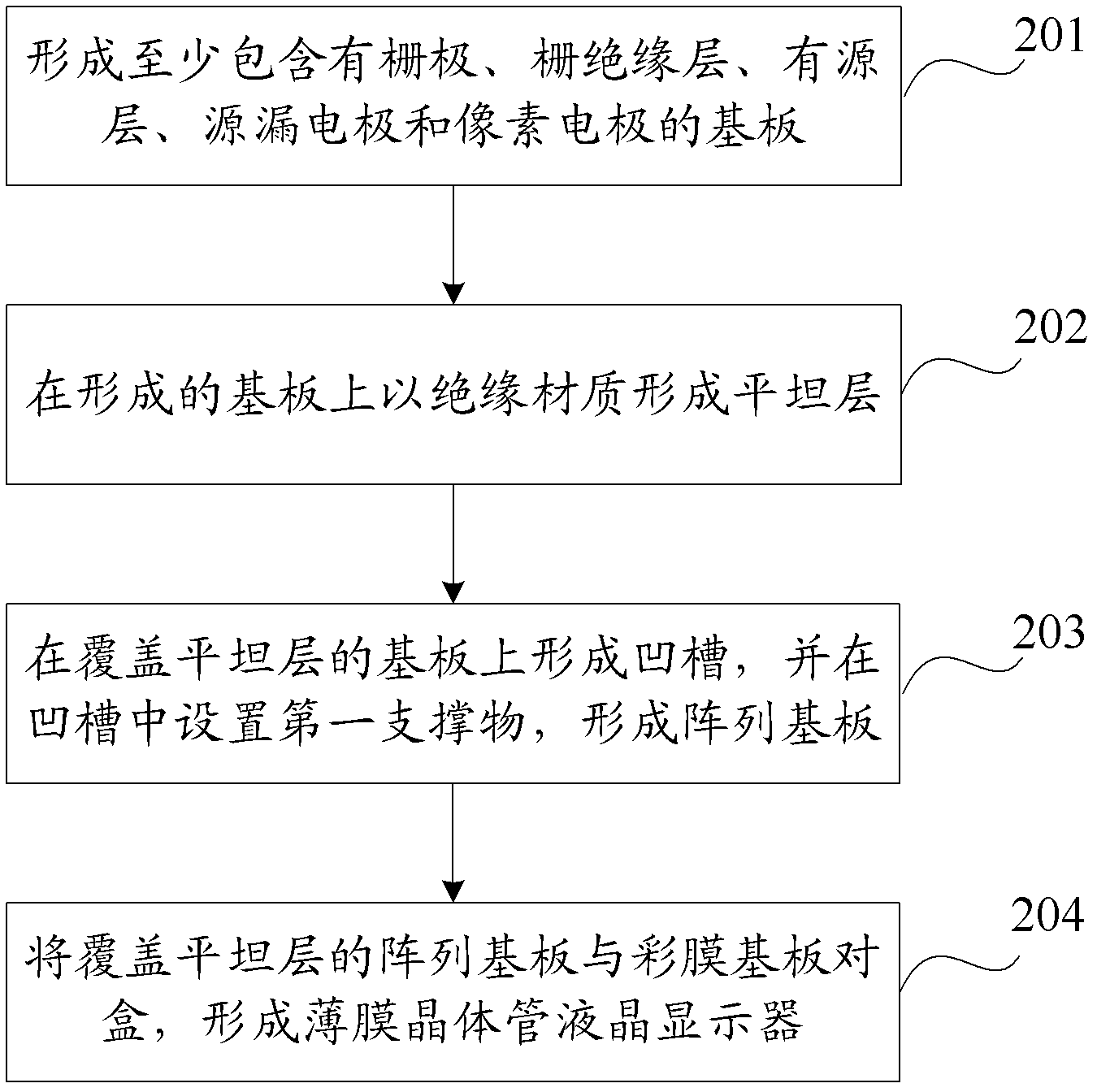

[0035] In an embodiment of the present invention, after forming a substrate including at least a gate, a gate insulating layer, an active layer, a source-drain electrode, and a pixel electrode, a planar layer is covered on the substrate, wherein the upper surface of the planar layer is a plane, Then, a groove is formed on the flat layer, and a first support is arranged in the groove, so that an array substrate is formed, and the array substrate and the color filter substrate are combined to form a thin film transistor liquid crystal display. In this way, since the upper surface of the flat layer is flat, the level difference caused by the different patterns of each layer of the array substrate is eliminated, and the chance of rubbing mura caused by the level difference is reduced, and there are grooves on the flat layer, which can reduce the movement of the support chance, improve the TFT-LCD picture quality.

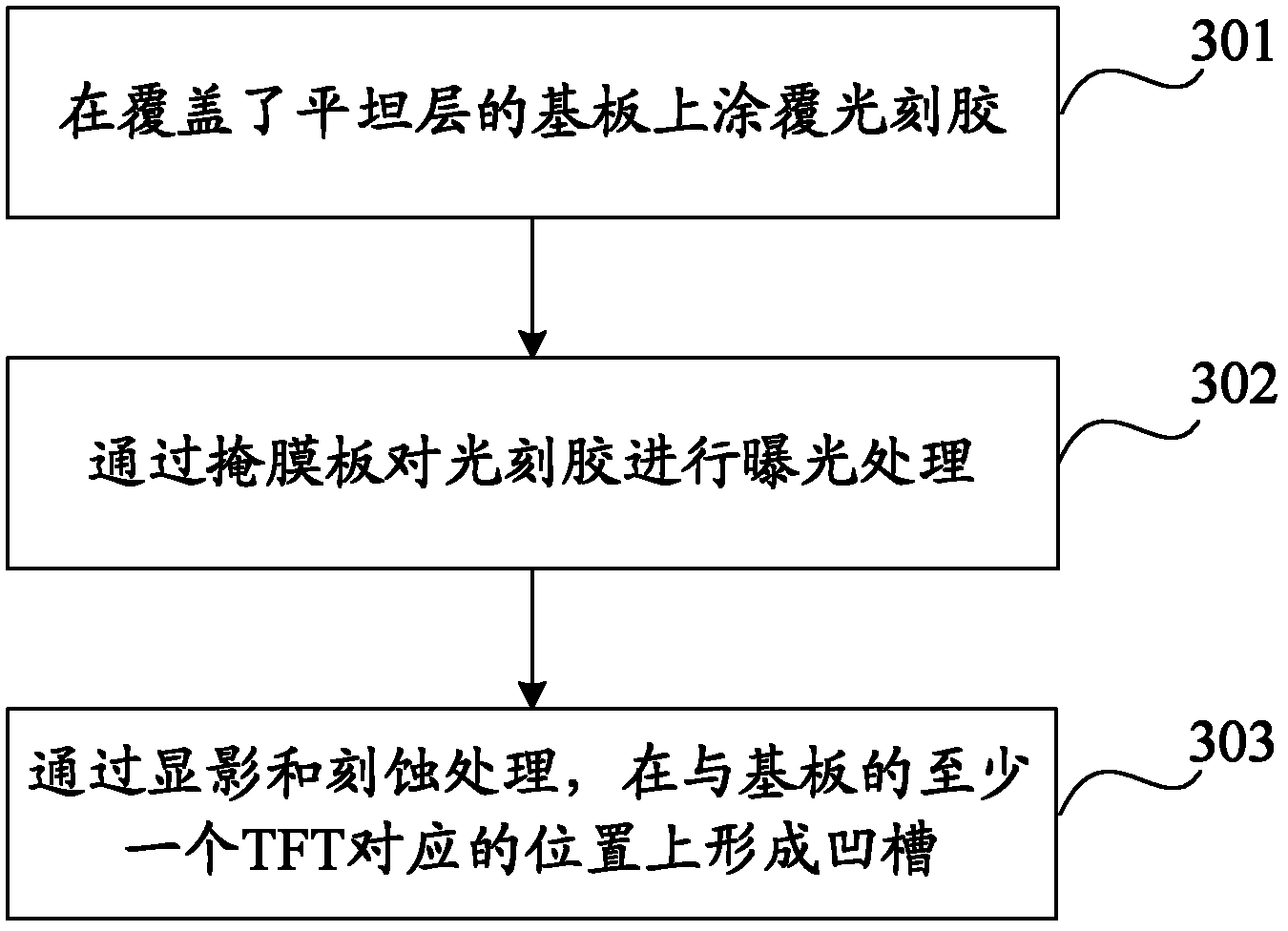

[0036] see figure 2 , The process of TFT-LCD production includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com