Testing device and method for bonding performance of fiber and mortar materials

A technology of bonding performance and mortar material, which is applied in the direction of measuring device, analyzing material, using mechanical device, etc., to achieve the effect of convenient operation and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

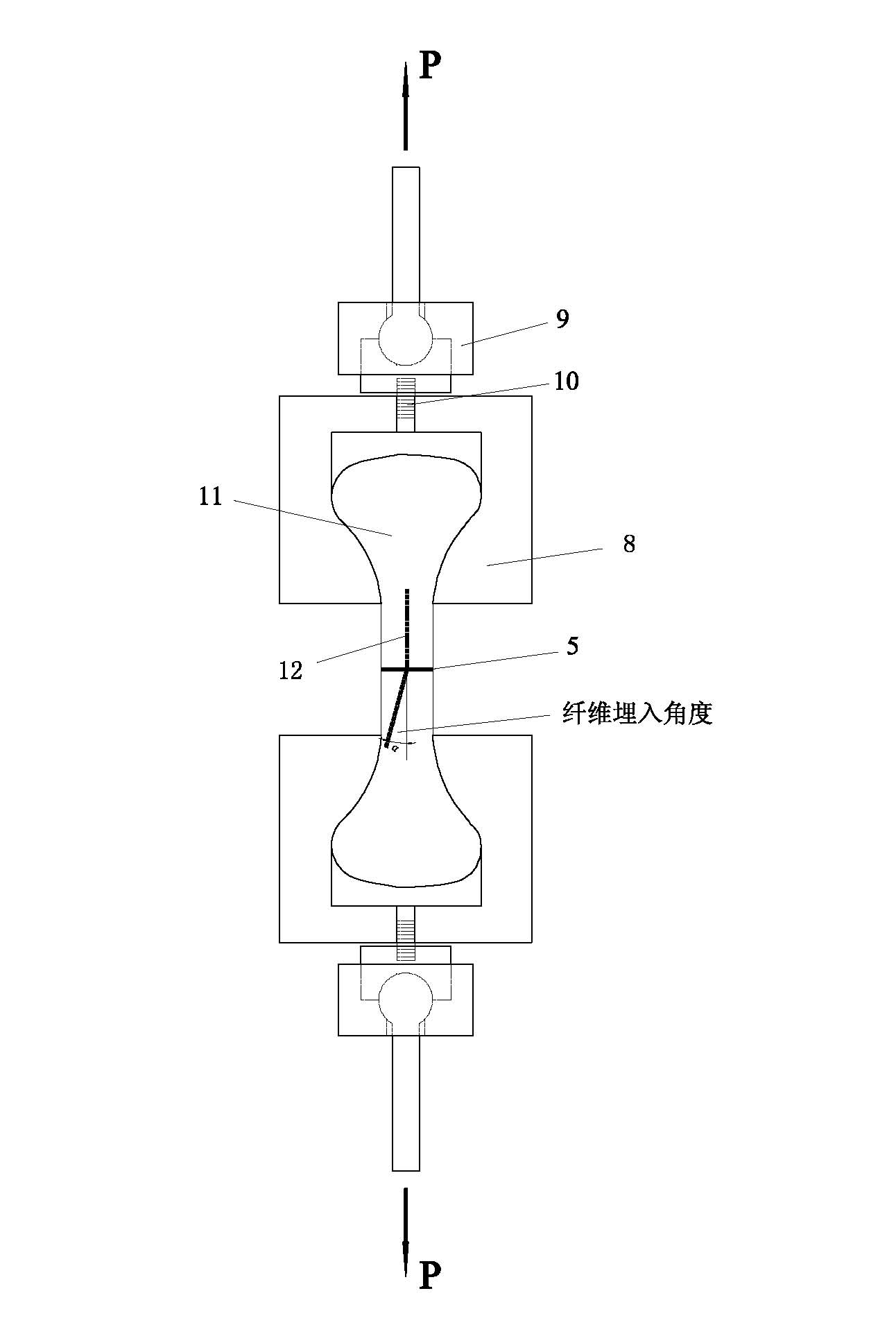

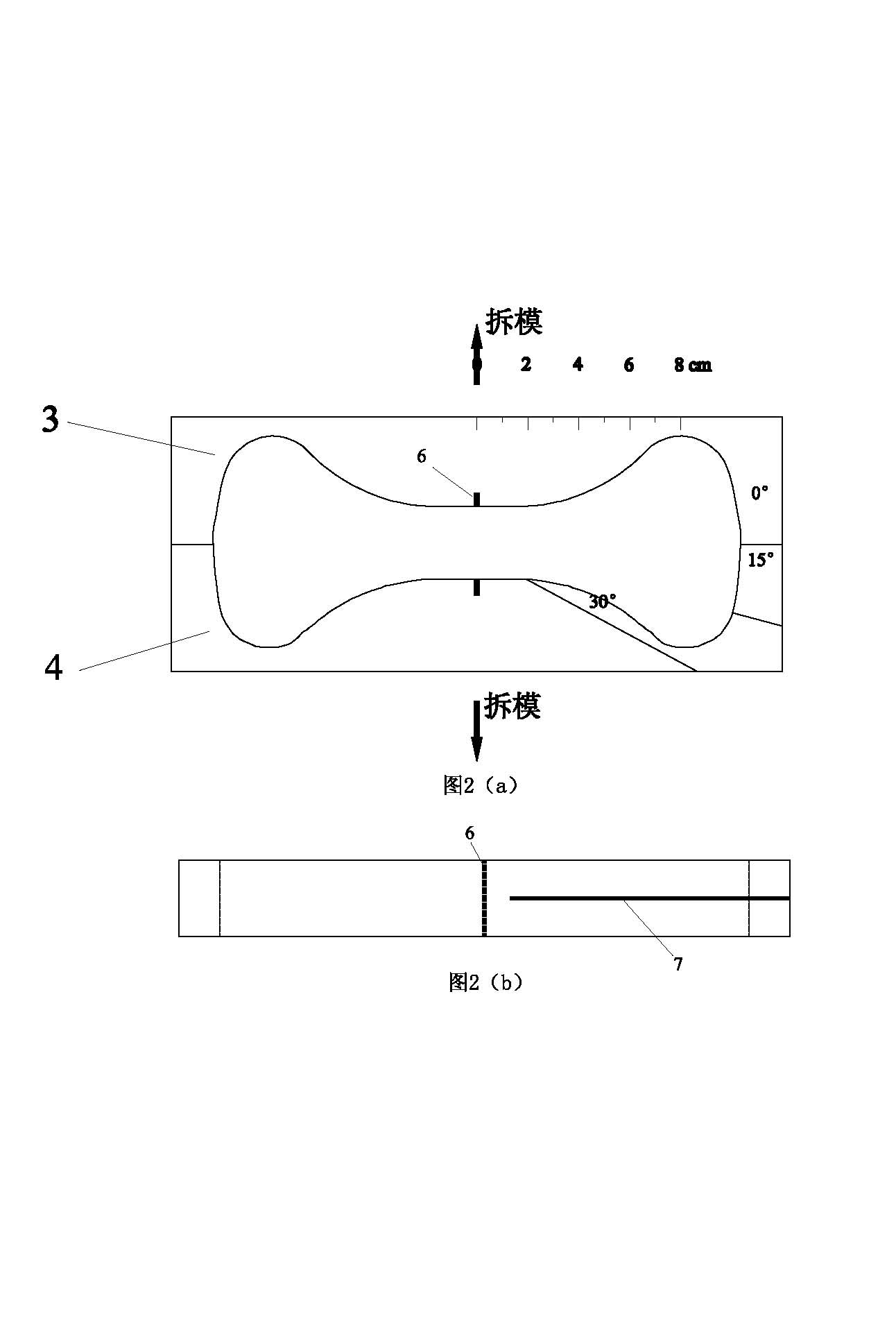

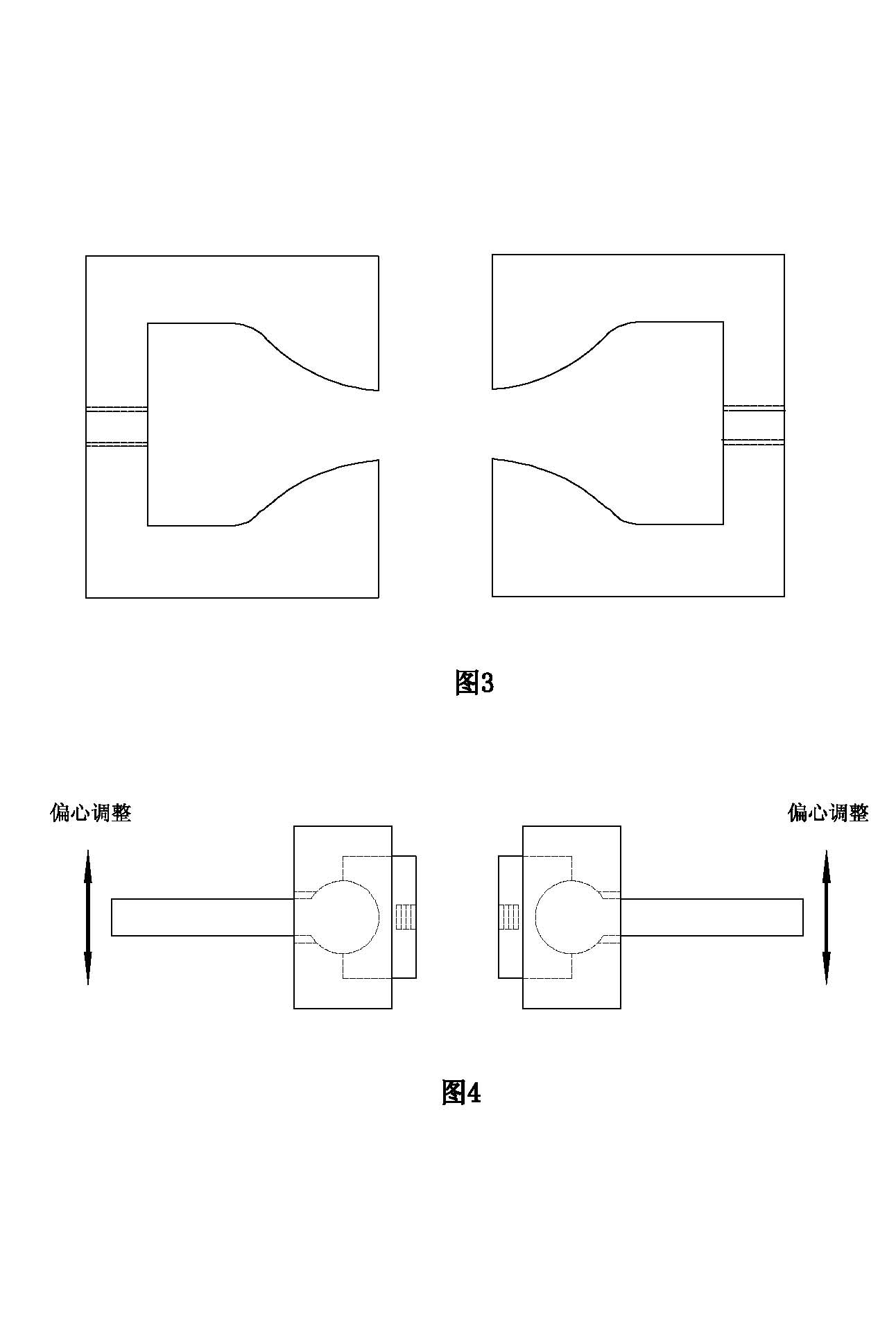

[0025] Such as Figure 1-4 shown.

[0026] A device for testing the bonding performance of fibers and mortar materials, which includes a test piece forming mold 1 ( figure 2 ) and tensile test fixture 2 ( image 3 , 4 ), the test piece forming mold 1 includes a left mold 3, a right mold 4 and a plastic insert 5, and the left mold 3 and the right mold 4 are spliced to form an "8" shaped cavity (such as figure 2 a) There is a card slot 6 for inserting one side of the plastic insert 5 at the left mold 3, the right mold 4 and the middle position, and the plastic insert 5 is provided with a hole for one end of the fiber to pass through , a number of through holes matching the fiber diameter, on one side of the left mold 3 and the right mold 4, a side transverse seam 7 communicating with the inner cavity is provided, and the side transverse seam 7 is fixed with a plastic insert 5 One end of the through-hole fiber 12 is connected to a connecting wire, such as figure 2 as ...

Embodiment 2

[0028] A method for testing the bonding performance of fibers and mortar materials, comprising preparation, clamping and tensile testing of a specimen, wherein the preparation steps of the specimen are:

[0029] First, according to the diameter of the fiber to be tested, punch some small holes in the center of the plastic insert, and then pass the fiber to be tested through the small holes;

[0030] Secondly, wind one end of the fiber to be tested into a circle or heat it into a pimple at high temperature to strengthen the anchorage of the end in the high-strength mortar and ensure that the end will not be debonded during tensile loading;

[0031] Thirdly, insert the plastic insert with the fiber to be tested into the slot in the middle of the "8"-shaped test piece forming mold, and divide the inner cavity of the test mold into two parts through the plastic insert;

[0032] Fourth, first pour high-strength mortar material into the molding mold of half of the test piece at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com