Method for preparing less layer graphene sheet

A technology of few-layer graphene and graphene sheets, which is applied in the field of rapid and high-yield preparation of few-layer graphene sheets, which can solve the problems of low graphene concentration, complicated process, and long time, and achieve high quality and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Weigh 50 mg of graphite powder in a reaction vessel, and under stirring, first slowly add 10 grams of chlorosulfonic acid into the graphite powder, and continue stirring for five minutes to uniformly mix the graphite powder and chlorosulfonic acid. Then, under the condition of not stopping stirring, the hydrogen peroxide of 4 grams is slowly added in the mixed solution of graphite powder and chlorosulfonic acid. By centrifuging at 12000rpm and washing 3 times with double distilled water, the purpose is to remove excess acid solution, and the product obtained after centrifugal washing is redispersed in chlorosulfonic acid after freezing (minus 40 degrees Celsius) and drying under vacuum conditions to obtain Dispersions. The dispersion was centrifuged again at 1500 rpm to remove unexfoliated graphite and partially exfoliated graphite deposited at the bottom, thereby obtaining high-quality few-layer graphene sheets with a yield of 75%.

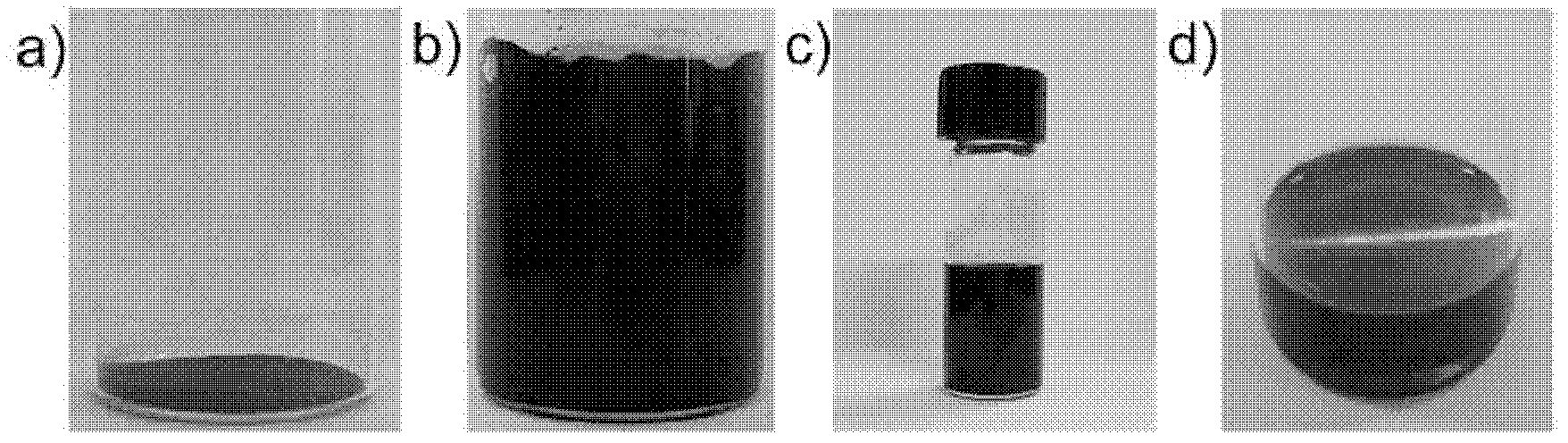

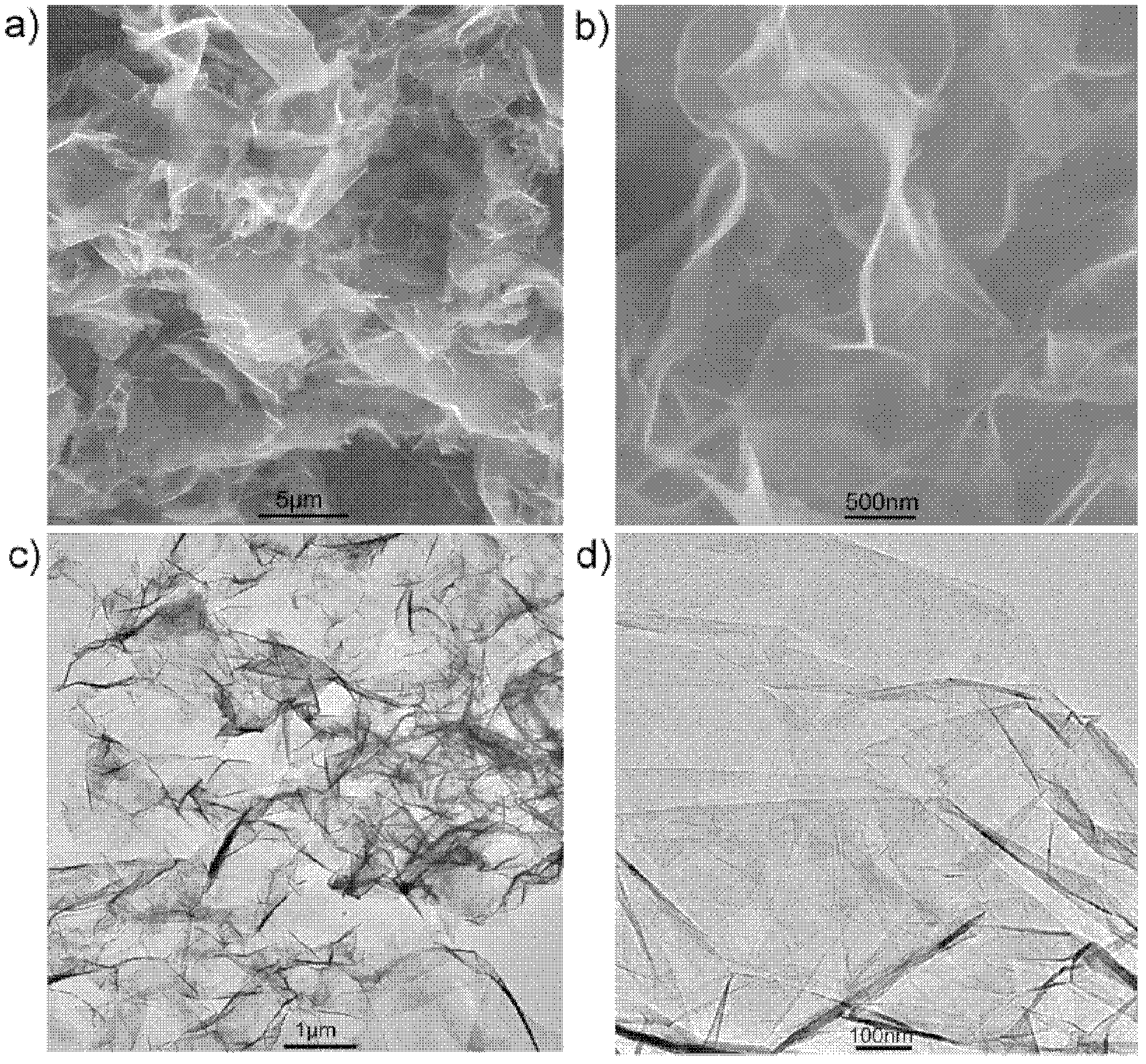

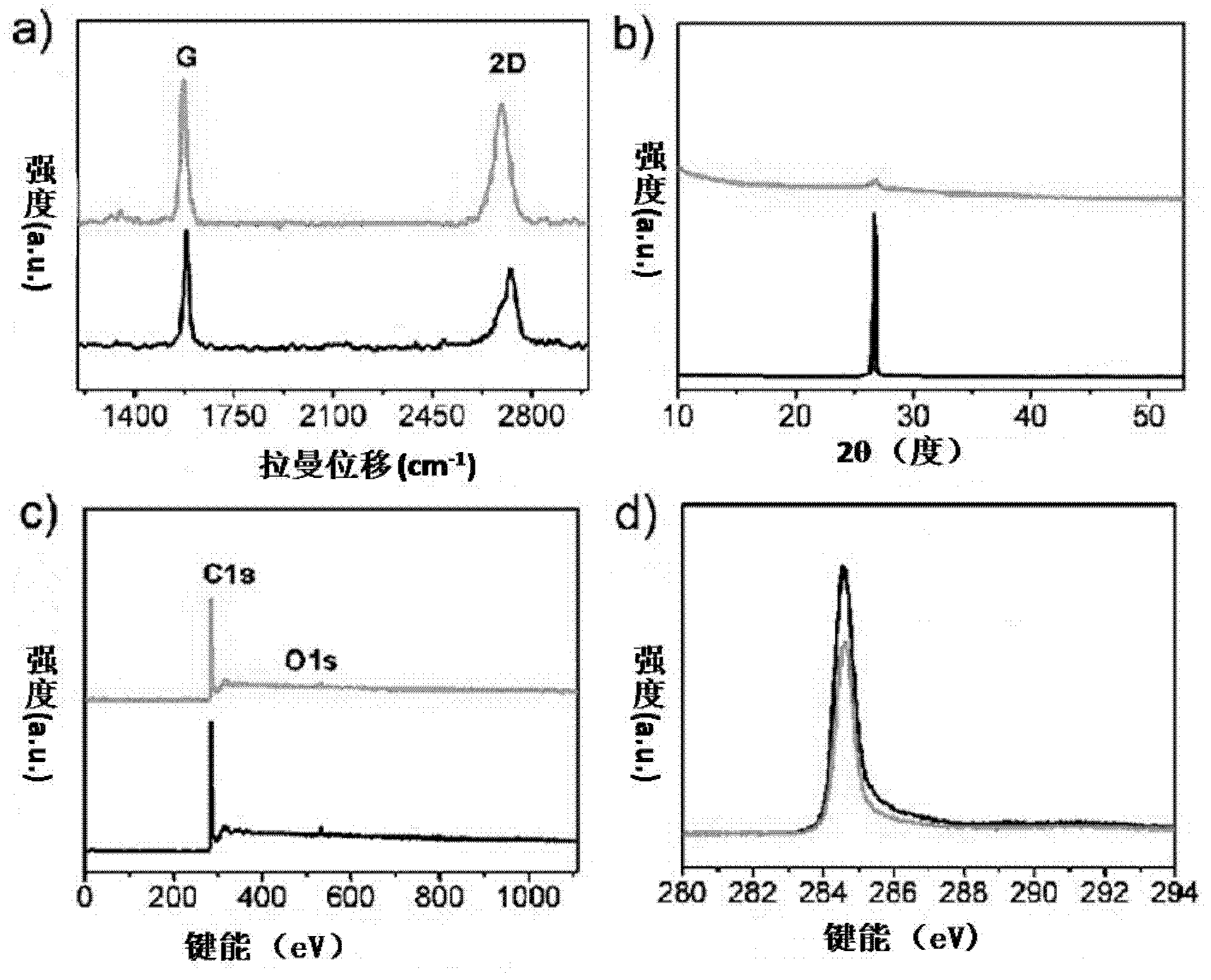

[0019] figure 1 It is the digital...

specific Embodiment approach 2

[0023] Weigh 50 mg of graphite powder in a reaction vessel, and under stirring, first slowly add 7.5 grams of chlorosulfonic acid into the graphite powder, and continue stirring for five minutes to uniformly mix the graphite powder and chlorosulfonic acid. Then, under the condition of not stopping stirring, the hydrogen peroxide of 4 grams is slowly added in the mixed solution of graphite powder and chlorosulfonic acid. By centrifuging at 12000rpm and washing 3 times with double distilled water, the purpose is to remove excess acid solution, and the product obtained after centrifugal washing is redispersed in chlorosulfonic acid after freezing (minus 40 degrees Celsius) and drying under vacuum conditions to obtain For the dispersion liquid, the obtained dispersion liquid was centrifuged again at 1500 rpm to remove unexfoliated graphite and partially exfoliated graphite deposited at the bottom, thereby obtaining high-quality few-layer graphene with a yield of 74%.

[0024] Fi...

specific Embodiment approach 3

[0025]Weigh 50 mg of graphite powder in a reaction vessel, and under stirring, first slowly add 5 grams of chlorosulfonic acid into the graphite powder, and continue stirring for five minutes to uniformly mix the graphite powder and chlorosulfonic acid. Then, under the condition of not stopping stirring, the hydrogen peroxide of 4 grams is slowly added in the mixed solution of graphite powder and chlorosulfonic acid. By centrifuging at 12000rpm and washing 3 times with double distilled water, the purpose is to remove excess acid solution, and the product obtained after centrifugal washing is redispersed in chlorosulfonic acid after freezing (minus 40 degrees Celsius) and drying under vacuum conditions to obtain For the dispersion liquid, the obtained dispersion liquid was centrifuged again at 1500 rpm to remove unexfoliated graphite and partially exfoliated graphite deposited at the bottom, thereby obtaining high-quality few-layer graphene with a yield of 75%.

[0026] Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com