Automatic torsion bar press fitting, measuring and straightening equipment

A straightening and equipment technology, applied in force/torque/work measuring instruments, measuring devices, metal processing equipment, etc., can solve the problems that a single equipment cannot meet the takt time requirements of automated assembly lines, the equipment structure is complex, and the process takt time is long. , to achieve the effect of short process cycle, high equipment integration and easy adjustment of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

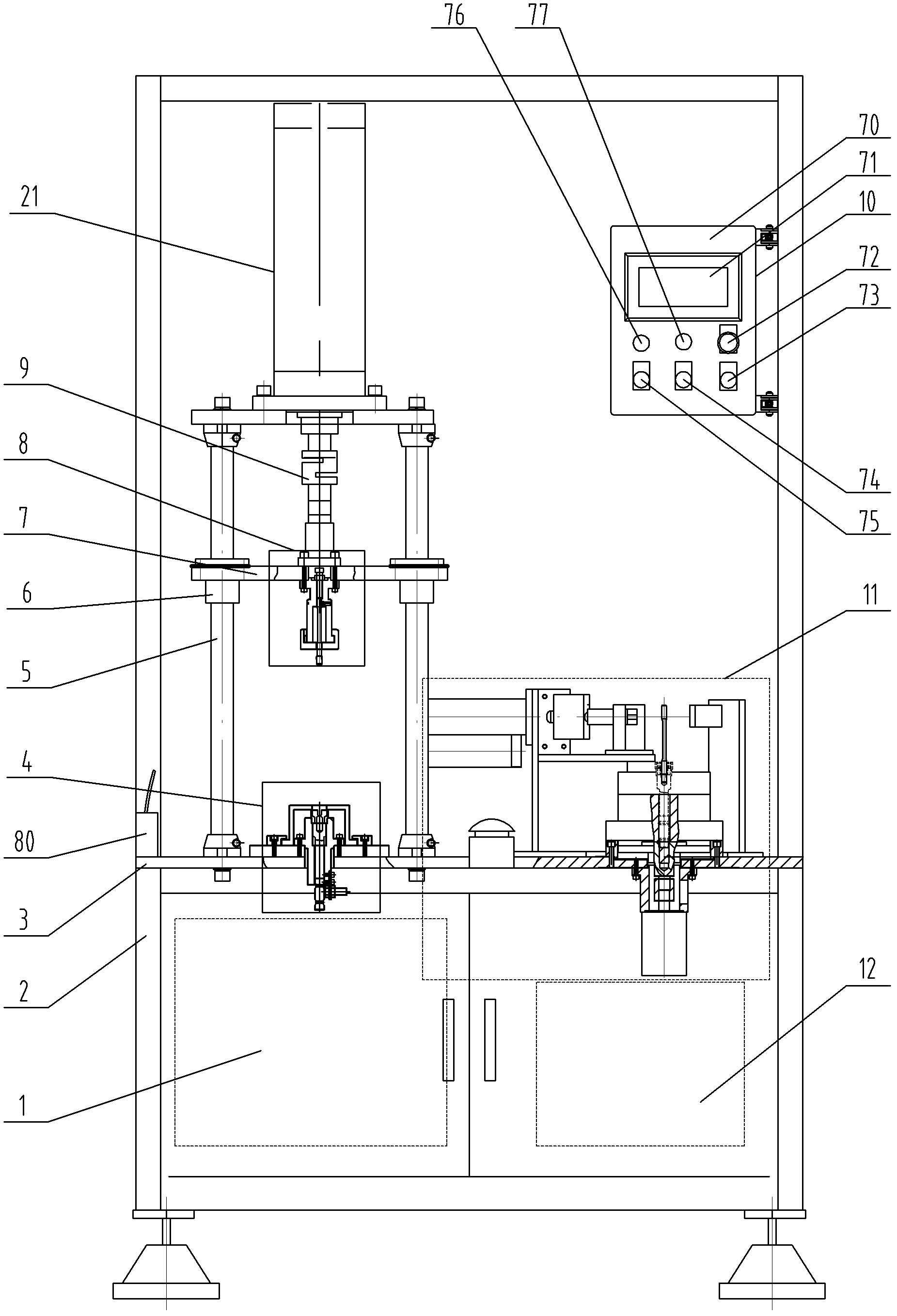

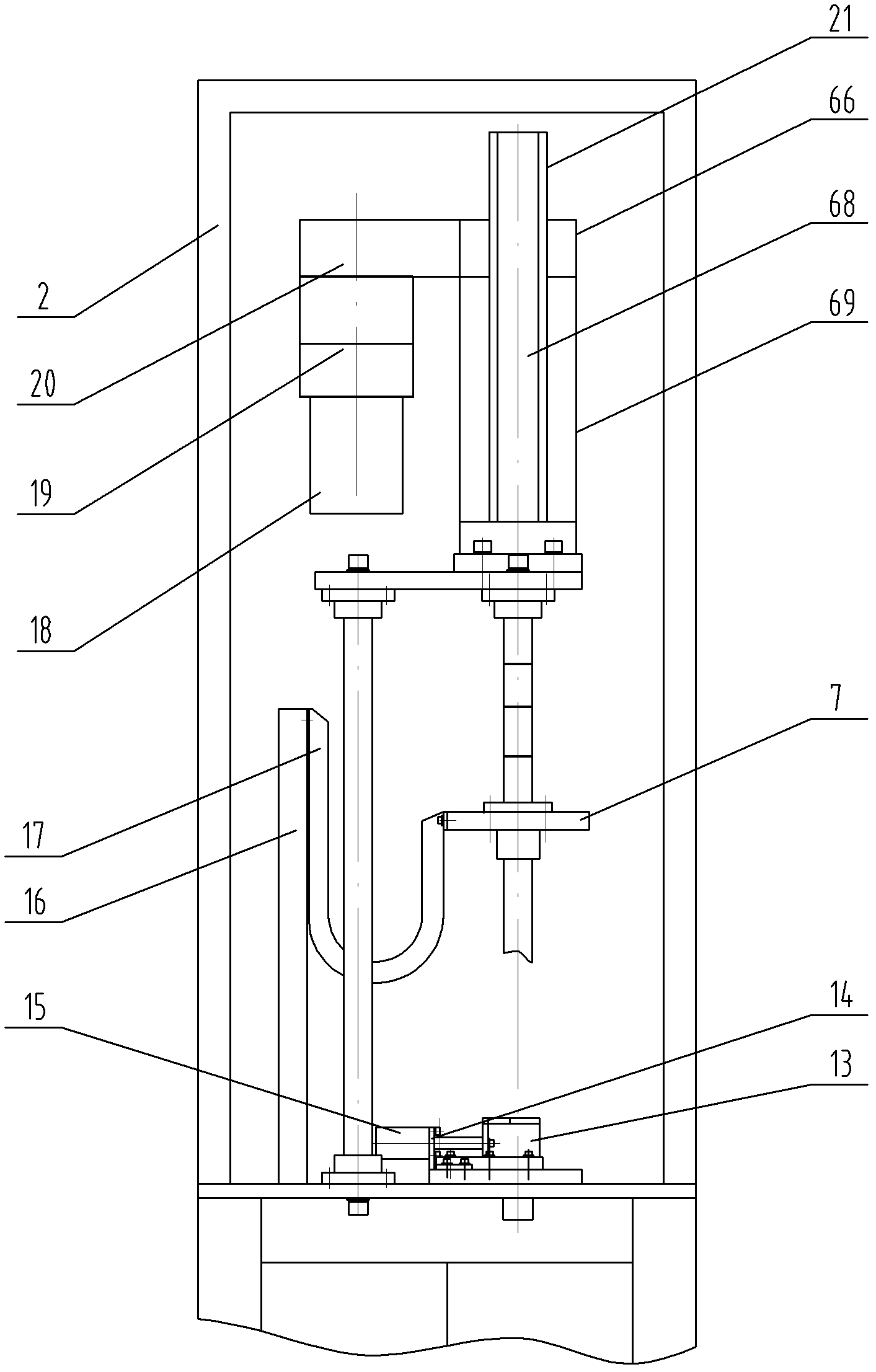

[0008] Specific implementation mode one: combine Figure 1-Figure 7 Explain that the torsion bar automatic press-fitting, measuring and straightening equipment of this embodiment includes an electric control system mounting plate 1, a frame 2, a platen 3, a lower clamp 4, a slide plate 7, an upper clamp 8, and a tension sensor 9. Man-machine interface component 10, measuring alignment mechanism 11, pneumatic system connecting plate 12, cylinder support 14, cylinder 15, first support 16, drag chain 17, press-fit AC servo motor 18, press-fit reducer 19, press-fit Install the synchronous belt transmission mechanism 20, the press-fit linear motion mechanism 21, four guide shafts 5 and four linear bearings 6, the press-fit linear motion mechanism 21 includes a press-fit screw 68 and a press-fit jacket 69;

[0009] The platen 3 is arranged horizontally and fixedly connected with the frame 2, the platen 3 is provided with a first through hole, the lower clamp 4 is arranged at the fir...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 , Figure 4 and Figure 5 Explain that the upper clamp 8 of this embodiment includes a tension cap 23, an upper clamp body 24, a bearing sleeve 25, an adjusting screw 26, a spring coil 27, a top post 28 and a steel ball 29;

[0011] The middle part of the upper end of the upper clamp body 24 is provided with a threaded hole, and the middle part of the lower end of the upper clamp body 24 is provided with an open inner cavity. In the open inner cavity of the clamp body 24, the lower end of the upper clamp body 24 is inserted in the tension cap 23 (quick connection can be realized), and the load-bearing sleeve 25 and the tension cap 23 are all provided with mounting holes, and the load-bearing sleeve 25 and The mounting holes of the tension cap 23 are coaxially arranged with the threaded hole and the connection hole of the upper clamp body 24, the adjusting screw 26 is threaded with the threaded hole of the upper cl...

specific Embodiment approach 3

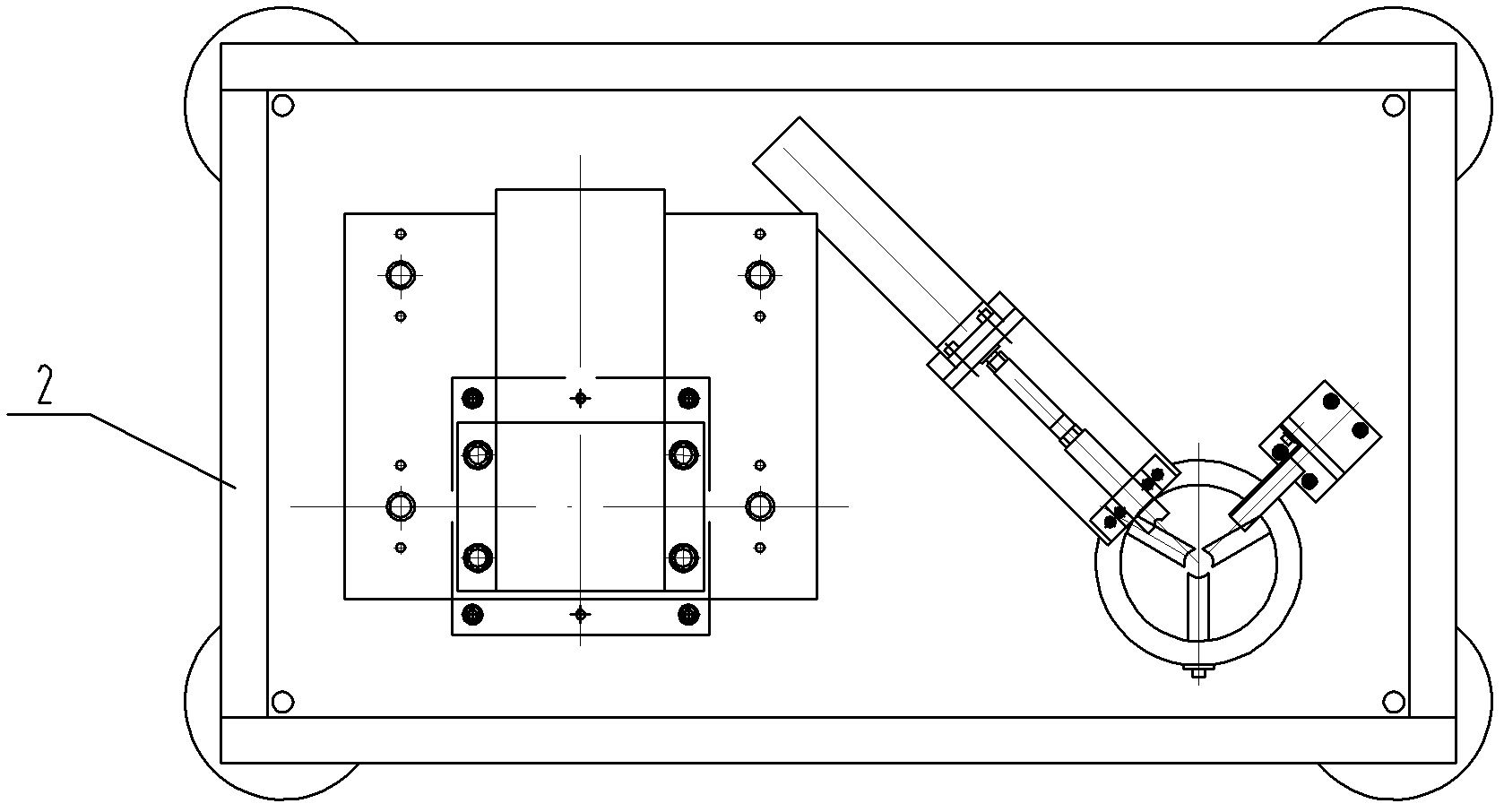

[0012] Specific implementation mode three: combination figure 1 , Figure 4 and Image 6 Explain that the lower clamp 4 of this embodiment includes a proximity switch 30, a proximity switch bracket 31, a lower clamp body 33, a bearing plate 34, a slider 13 and an adjustment plate 35;

[0013] The adjustment plate 35 is fixedly connected with the upper end surface of the platen 3, the adjustment plate 35 is provided with a third through hole communicating with the first through hole of the platen 3, the outer wall of the lower clamp body 33 is provided with a boss, and the lower clamp body 33 The lower end of the lower end of the adjustment plate 35 and the first through hole of the platen 3 are sequentially pierced, and the boss of the lower clamp body 33 is affixed to the upper end surface of the adjustment plate 35. The position in the height direction is adjustable, the proximity switch 30 is connected with the proximity switch bracket 31, the proximity switch bracket 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com