Amino acid chelating compound organic feed additive and production method thereof

An organic feed and amino acid technology, applied in animal feed, animal feed, applications, etc., can solve problems affecting the central nervous system of animals, prone to fractures, and blocked keratin synthesis, so as to improve environmental pollution and reduce internal energy The effect of high consumption, absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

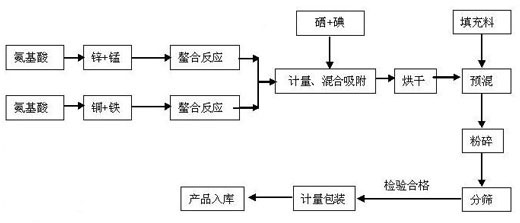

Method used

Image

Examples

Embodiment 1

[0050] First, put 10g of methionine, 10g of lysine, 10g of glutamic acid, 10g of cystine, 3g of manganese sulfate and 5g of zinc sulfate heptahydrate into the No. 1 reactor for chelation reaction. The temperature is controlled at 80-100°C. Time 5-8 hours. Then put 10g of methionine, 10g of lysine, 10g of glutamic acid, 10g of cystine, 0.5g of copper sulfate and 0.1 of ferrous sulfate heptahydrate into No. 2 reactor for chelation reaction, and the temperature is controlled at 80-100°C , The reaction time is 5-8 hours. Then add 0.05g of calcium iodate and 0.05g of sodium selenite into the chelate obtained by reacting with reactor No. 1 and No. 2 for metering, mixing and adsorption, and then use air flow or hot air to dry and dry; then add wheat rice Stone or montmorillonite is premixed, and then pulverized by a pulverizer; then sieved, inspected, and then measured and packaged to obtain the product.

Embodiment 2

[0052] First, put 20g of methionine, 20g of lysine, 20g of glutamic acid, 20g of cystine, 5g of manganese sulfate and 8g of zinc sulfate heptahydrate into the No. 1 reactor for chelation reaction. Time 5-8 hours. Then put 20g of methionine, 20g of lysine, 20g of glutamic acid, 20g of cystine, 1g of copper sulfate and 0.5g of ferrous sulfate heptahydrate into No. 2 reactor for chelation reaction, and the temperature is controlled at 80-100°C , The reaction time is 5-8 hours. Then add 0.1g of calcium iodate and 0.1g of sodium selenite to the chelate obtained by reacting with reactor No. 1 and No. 2 for metering, mixing and adsorption, and then use air flow or hot air to dry and dry; then add wheat rice Stone or montmorillonite is premixed, and then pulverized by a pulverizer; then sieved, inspected, and then measured and packaged to obtain the product.

Embodiment 3

[0054] First, put 40g of methionine, 40g of lysine, 40g of glutamic acid, 40g of cystine, 5g of manganese sulfate and 8g of zinc sulfate heptahydrate into the No. 1 reactor for chelation reaction. Time 5-8 hours. Then put 40g of methionine, 40g of lysine, 40g of glutamic acid, 40g of cystine, 2g of copper sulfate and 3g of ferrous sulfate heptahydrate into the No. The reaction time is 5-8 hours. Then add 1 g of calcium iodate and 1 g of sodium selenite to the chelates obtained by reacting with reactor No. 1 and No. 2 for metering, mixed adsorption, and then adopt air flow or hot air drying; then add medical stone or The montmorillonite is premixed, and then pulverized by a pulverizer; then sieved, inspected, and then measured and packaged to obtain the product.

[0055]

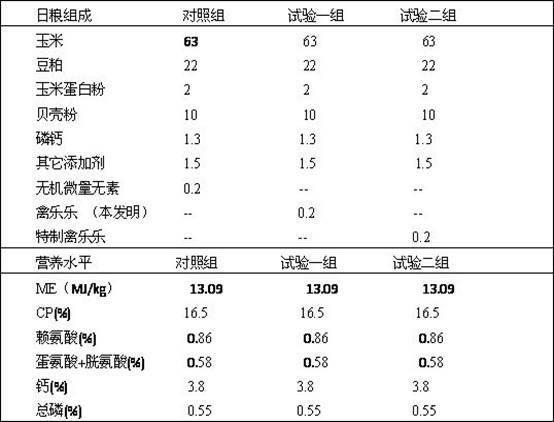

[0056] 3. Amino acid chelated compound organic feed additive—main nutrient composition index of Qinlele products

[0057]

[0058] In 2009, Guangxi Feed Monitoring Institute, Nanning Zewell Feed Co., L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com