A kind of preparation method of fe-si-al soft magnetic material with high microwave magnetic permeability

A fe-si-al, soft magnetic material technology, applied in the direction of inorganic material magnetism, can solve the problems of large electrical conductivity, difficult to improve microwave permeability, high density, etc., to achieve convenient operation, improve microwave permeability, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

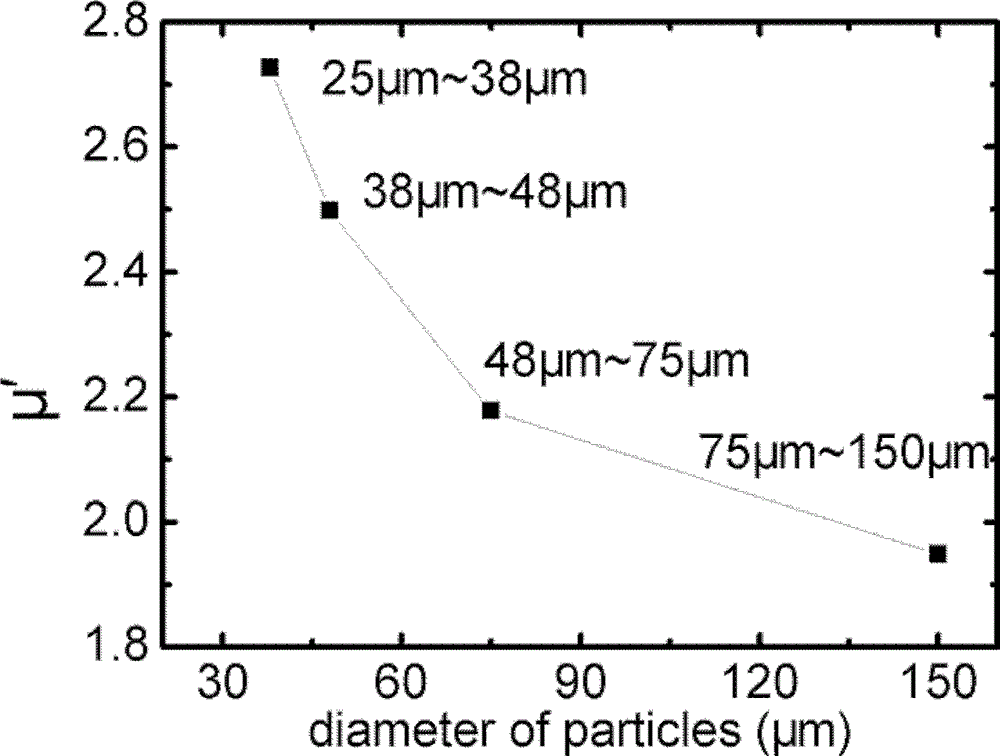

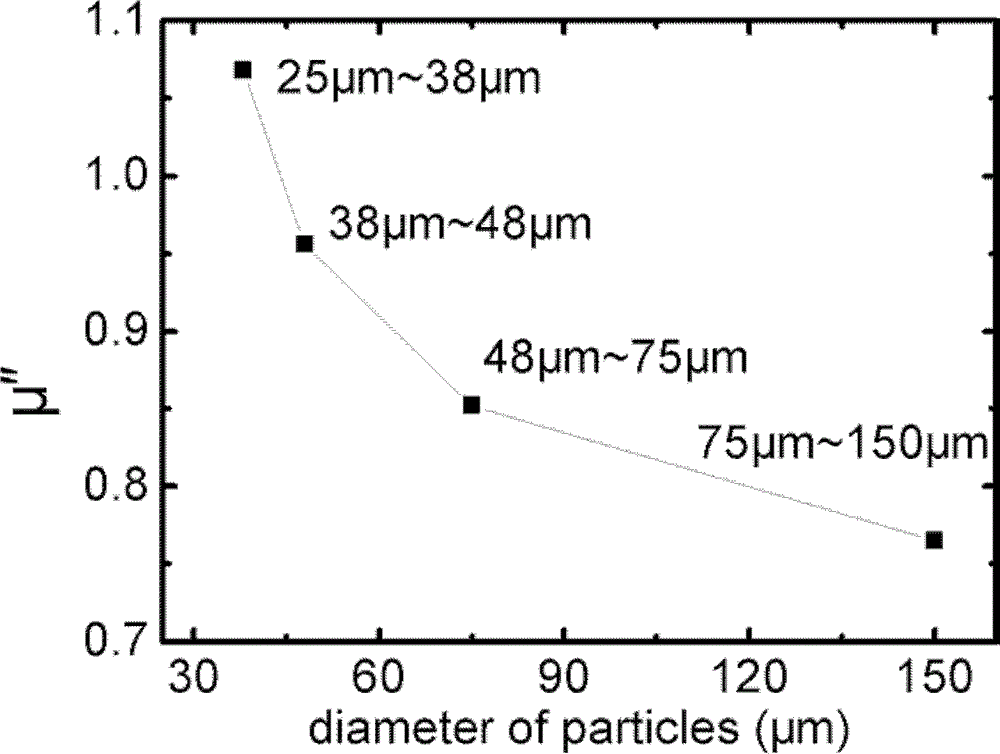

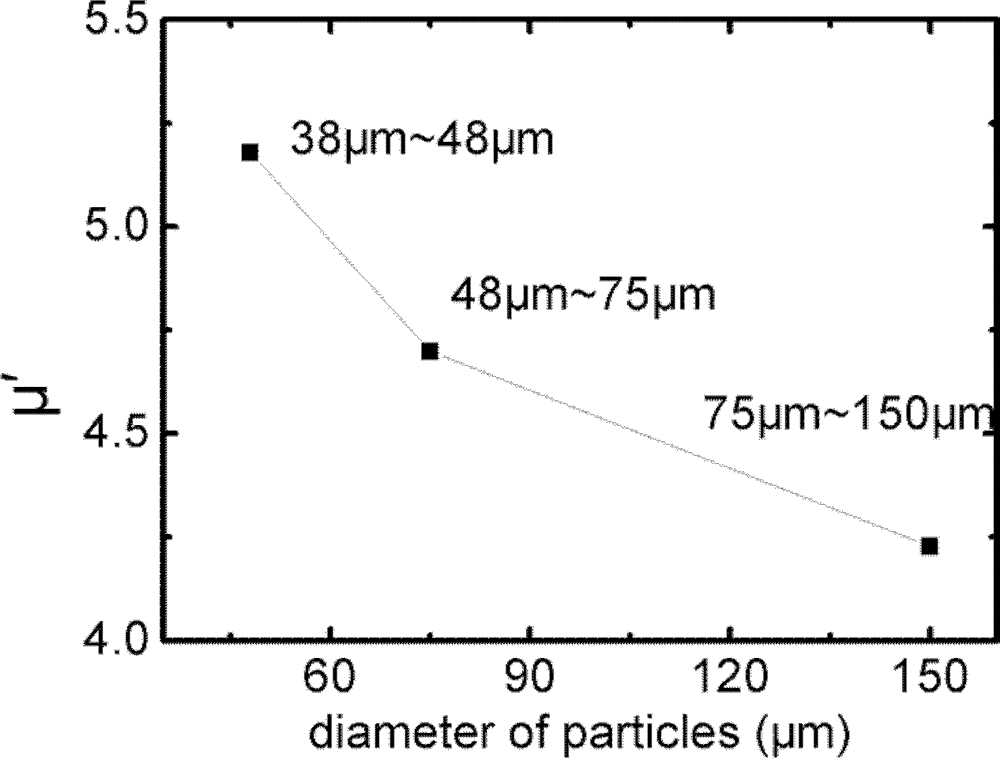

[0036] The present invention uses the Fe-Si-Al alloy powder obtained by the water mist method to control the particle size of the powder by the sub-sieve method, and then performs flake treatment on the powder in different particle size ranges, and finds Fe-Si-Al alloy powder with a small particle size. The microwave permeability of Si-Al alloy powder can be greatly improved after flaky treatment.

[0037] The present invention comprises the following steps:

[0038] 1) 100-mesh Fe-Si-Al raw powder is sieved through 100-mesh (150μm), 200-mesh (75μm), 300-mesh (48μm), 400-mesh (38μm) and 500-mesh (25μm) sieves to obtain 75μm-150μm , 48μm~75μm, 38μm~48μm, 25μm~38μm and less than 25μm Fe-Si-Al alloy powder.

[0039]2) Put the Fe-Si-Al alloy powders obtained in step 1) into the high-energy ball mill for flaking treatment with the particle size ranges of 75 μm to 150 μm and 48 μm to 75 μm, respectively, at a ratio of 25:1. Weigh quantitative Fe-Si-Al alloy powders and balls of tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com