Servo drive system and servo drive method for numerically controlled tool rest

A servo drive, servo drive technology, applied in the direction of digital control, electrical program control, etc., can solve the problem of the servo drive being easy to lose or increase pulses, and achieve the effect of avoiding inaccurate positioning, saving costs, and reducing the amount of interfaces and programming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

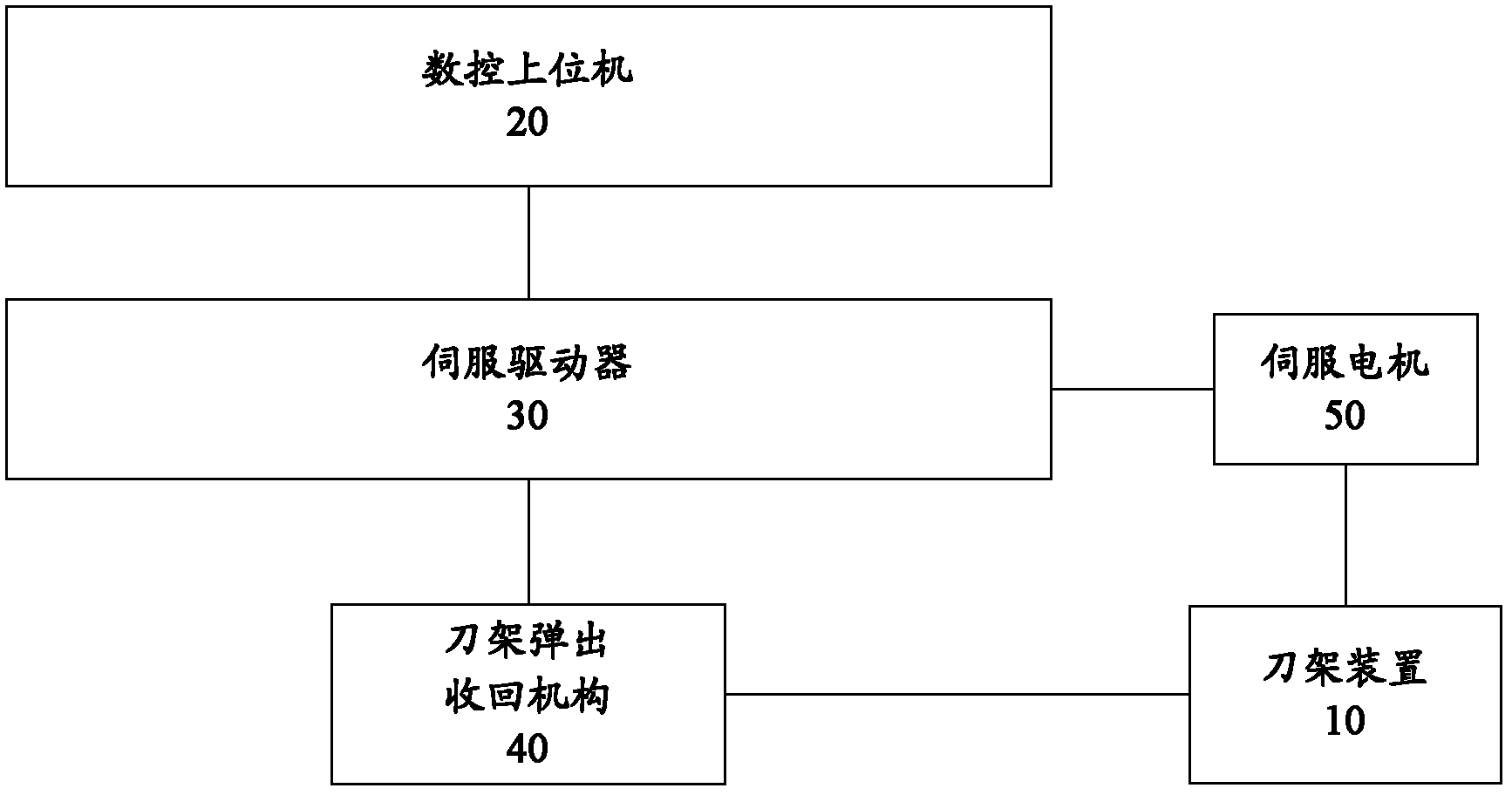

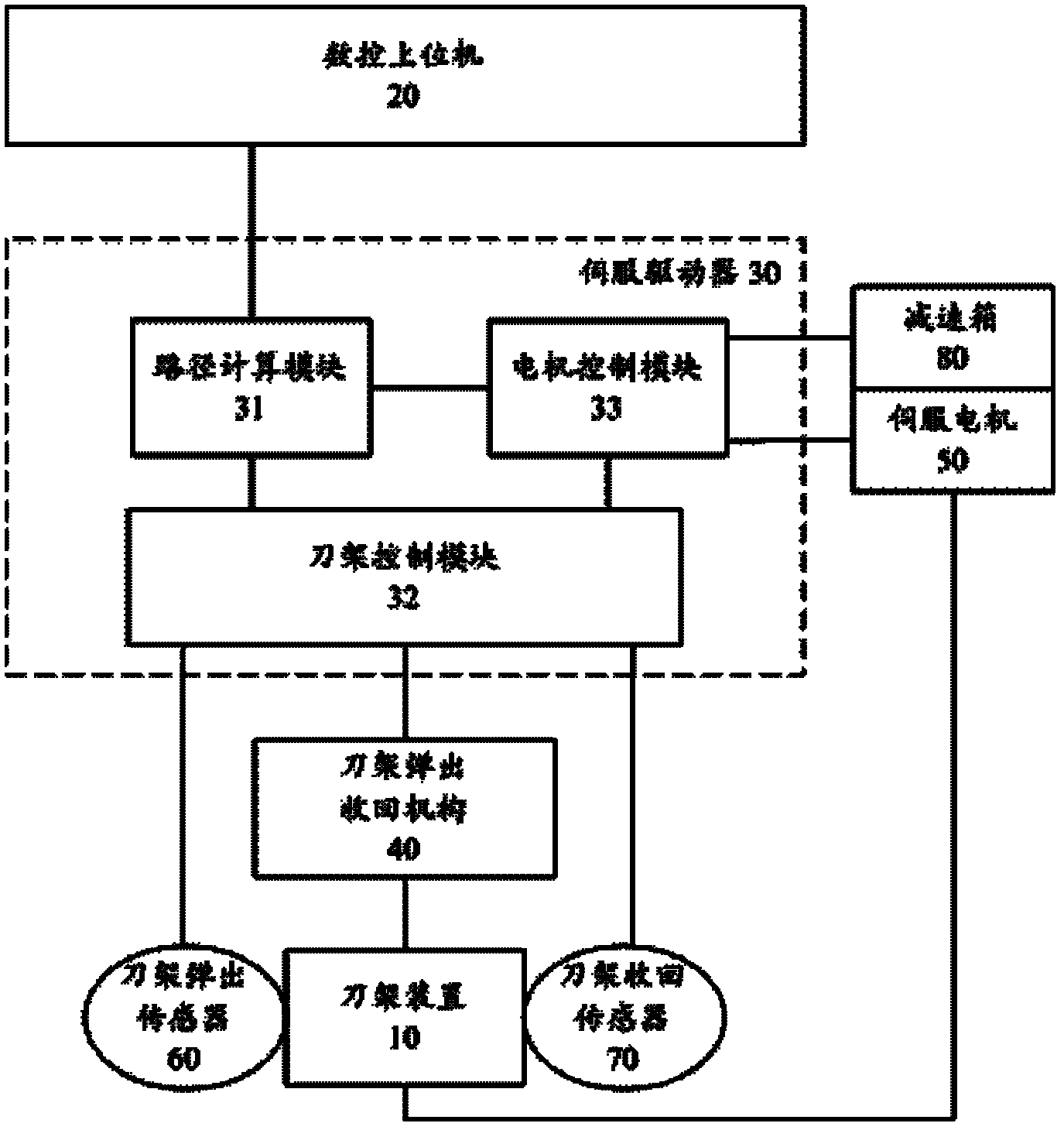

[0036] see figure 1 , which is a block diagram of the first embodiment of the servo drive system of the CNC tool rest according to the present invention. like figure 1 As shown, the servo drive system of the CNC tool rest provided by this embodiment includes: a tool rest device 10 , a numerical control host computer 20 , a servo driver 30 , a tool rest ejection and retraction mechanism 40 and a servo motor 50 .

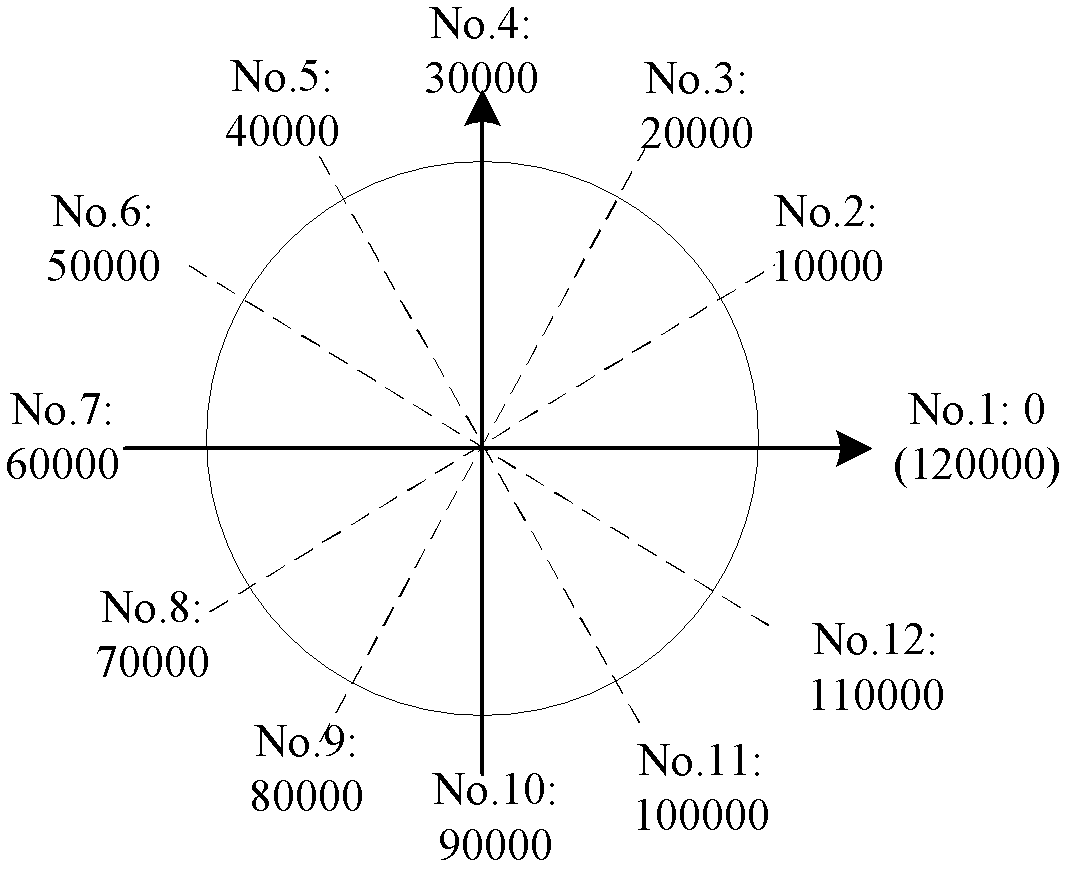

[0037] The tool holder device 10 of the present invention may be a tool holder used by various types of machine tools or machining centers. The tool holder device 10 includes a plurality of tool holders, and each tool holder is programmed with a tool number in sequence. The numerical control host computer 20 can send a tool change com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com