Real-time monitoring method of each component beam intensity and injection dosage of mixed ion beam

A technology of mixing ion beam and beam intensity, which is applied in the application field of ion beam technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

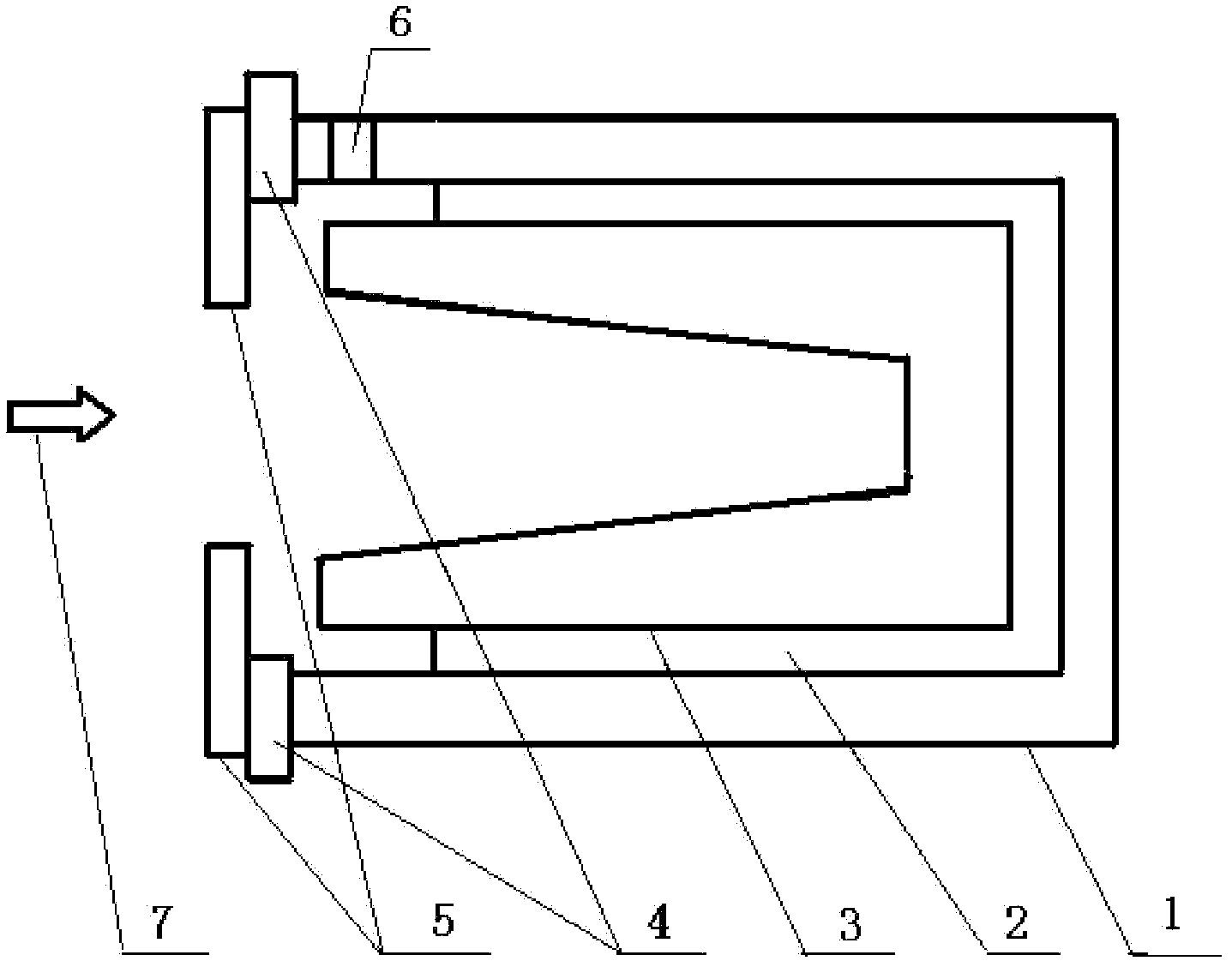

[0050] like figure 1 As shown, the Faraday cup used in the present invention includes: a metal shielding cylinder 1 ; an insulating layer 2 ; a metal receiving cylinder 3 ; an insulating isolation ring 4 ; a suppression electrode 5 ; exist figure 1 Among them, 7 is the beam current to be measured.

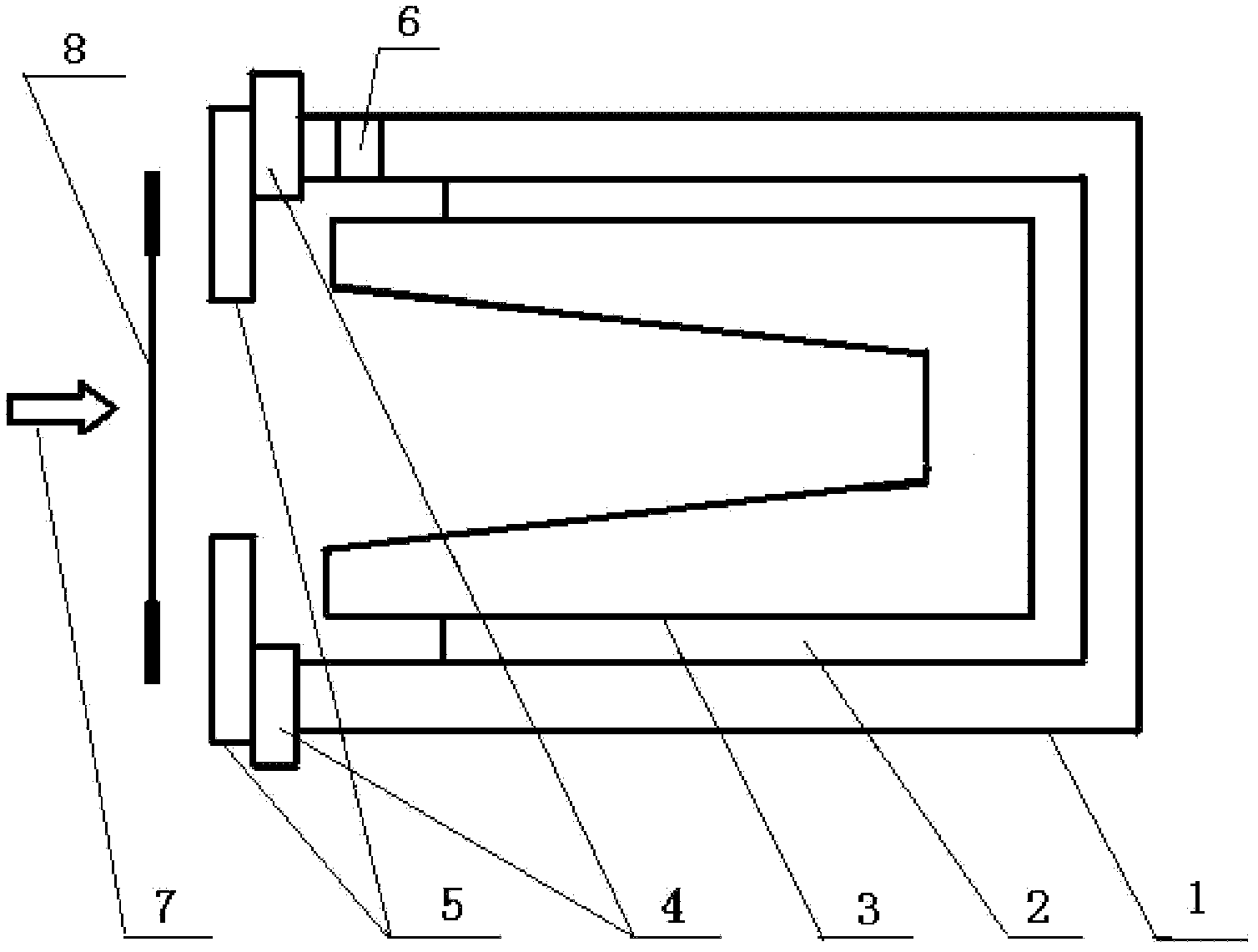

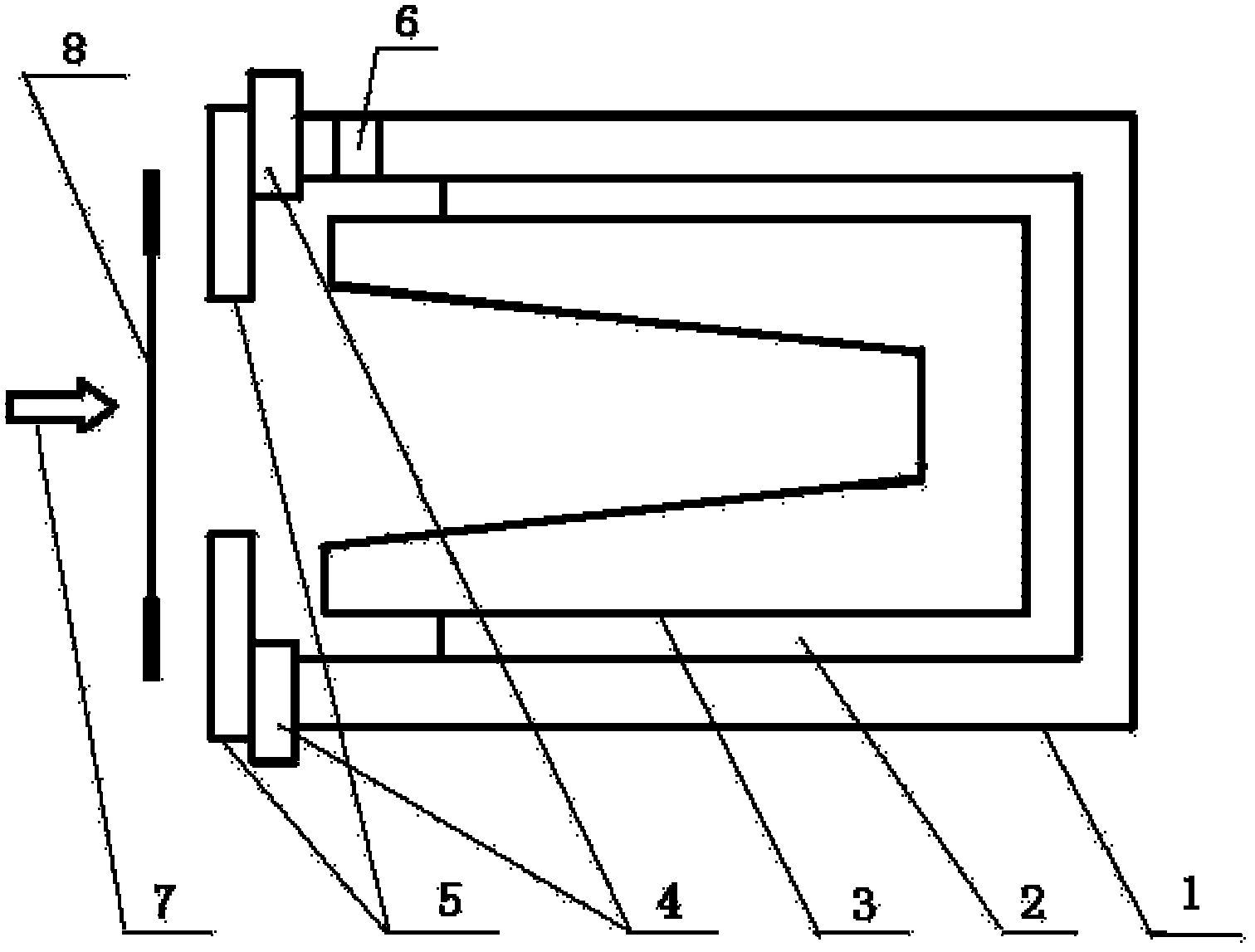

[0051] like figure 2 As shown, a solid pick 8 is placed between the sampling velocity Faraday cup and the beam to be measured.

[0052] The implementation of the present invention will be described in detail below in conjunction with the examples.

[0053] Large-area 3MeV protons and 25MeV Si produced by two accelerators 4+ Homogenously mixed beams with adjustable individual flow intensities. The monitoring method of the implanted dose of each component when the mixed beam of two ions irradiates the sample:

[0054] (1) Select the Faraday cup for sampling sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com