Leaf sheath tissue section manufacturing method for enabling users to observe callose of rice leaf sheath tissues

A callose and leaf sheath technology, applied in the field of microscopic tissue sectioning, can solve problems such as uneven thickness, difficulty in obtaining tissue structure, and large cell cavity, and achieve the effects of improving work efficiency, solving tissue fragility, and clear images

Inactive Publication Date: 2012-08-01

ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it is difficult to cut very thin with bare hands, and it is easy to produce uneven thickness

Due to the difference in water content between rice leaf tissue and leaf sheath tissue, and the cell cavity of the leaf sheath tissue is large and thin, air bubbles often exist in the leaf sheath tissue after sampling, which cannot be sliced by hand. The slice is easily broken and incomplete, and it is difficult to obtain a complete tissue structure.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0022] Rice variety and growth period: TN1, seedling stage

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

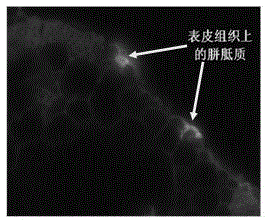

A leaf sheath tissue section manufacturing method for enabling users to observe callose of rice lead sheath tissues belongs to the technical field of micro-structural slicing and includes: (1) preprocessing of materials; (2) sample fixing; (3) section freezing; (4) section unfolding; (5) dying; and (6) microscopic observation and photographing. The leaf sheath tissue section manufacturing method remarkably shortens time for sample fixing, slicing and dying, basically the whole process from preprocessing of samples to observation and photographing under a fluorescence microscope can be finished in about 12 hours, the section obtained through the lead sheath tissue section manufacturing method is complete in tissue structure, the images are clear, and simultaneously the leaf sheath tissue section manufacturing method effectively solves the problem that slicing with hands can lead the tissues of the materials to be fragile, thickness of the sections to be uneven, a paraffin slicing process is complex, the period is long and the like. Working efficiency is remarkably improved.

Description

technical field [0001] The invention belongs to the technical field of microtissue sectioning, and in particular relates to a leaf sheath tissue preparation method for observing callose of rice leaf sheath tissue. Background technique [0002] The plant vascular system is composed of phloem and xylem. It is the main transport organization throughout the whole plant, responsible for long-distance transportation in the plant, and is the channel for plants to transport photosynthetic products, water and mineral nutrients. Phloem tissue is composed of sieve tubes, companion cells and parenchyma cells. Phloem sieve tubes contain callose, callose synthase, bast protein and other substances, which play an important role in regulating the metabolism of sieve tubes. The synthesis and decomposition of callous (the main component is β-1,3-glucan) is directly related to the normal growth and metabolism process of plants, and plays an important role in plant sieve tube metabolism, gameto...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N1/28G01N1/30G01N1/42

Inventor 陈建明杨丽张珏锋何月平

Owner ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com