Oil surface thermograph for transformer

A transformer and oil level technology, applied in thermometers, instruments, thermometers with electric/magnetic elements that are directly sensitive to heat, etc., can solve the problems of low temperature display and control accuracy, easy failure and damage, complex structure, etc. , to achieve the effect of strong anti-electromagnetic interference ability, improved reliability and service life, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

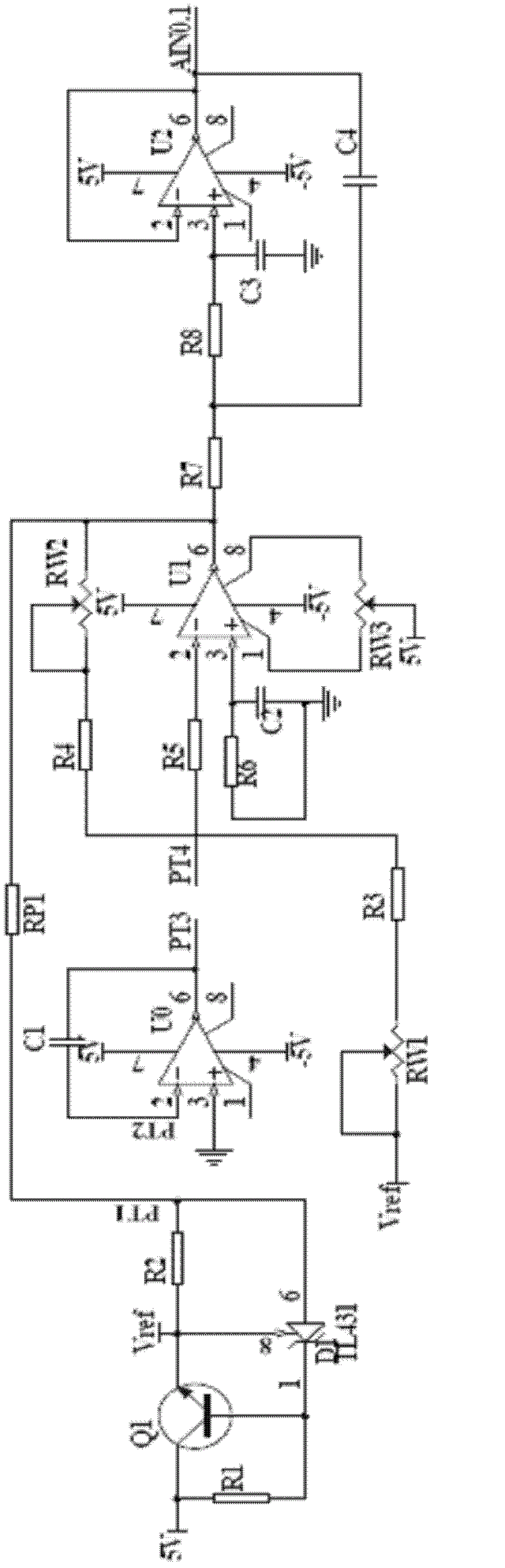

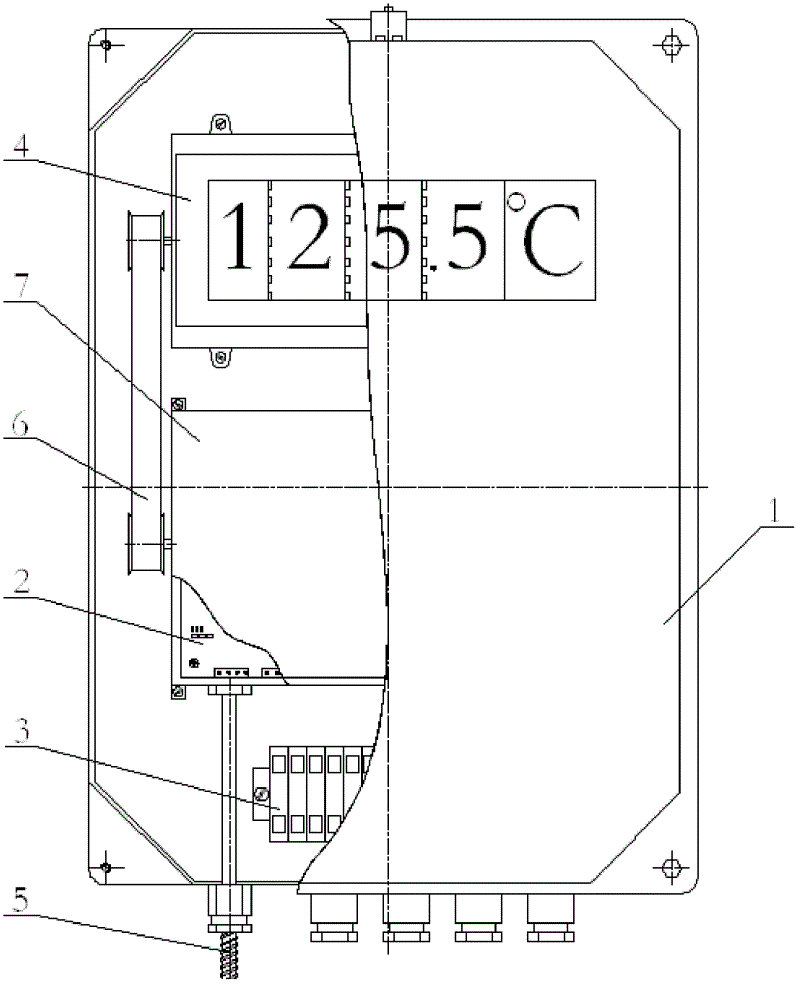

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments of the present invention. Such as figure 1 As shown: the instrument control module 2, the terminal block 3, and the mechanical counter 4 are installed in the housing 1, and the temperature sensor 5 and the synchronous pulley assembly 6 are connected to the instrument control module 2. The instrument control module 2 is placed in the anti-electromagnetic Inside the housing 7 of interference design, the instrument control module 2 is mainly composed of a signal conditioning acquisition circuit 201, a single-chip microcomputer 202, a data transmission circuit 203, a temperature signal conversion circuit 204, a motor module 205, a relay 206, and a watchdog 207.

[0023] refer to figure 2 As shown, it is a functional block diagram of an embodiment of the present invention. The temperature sensor 5 generates an electrical signal by sensing changes in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com