Method for measuring depth of roller body hardening layer

A technology for the depth of the hardened layer and the roll body, which is applied in the field of measuring the depth of the hardened layer of the roll body, can solve the problems of time-consuming, labor-intensive, cost consumption, large consumption of test roll materials, and large consumption of test materials to ensure quality, The effect of short test period and detailed test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

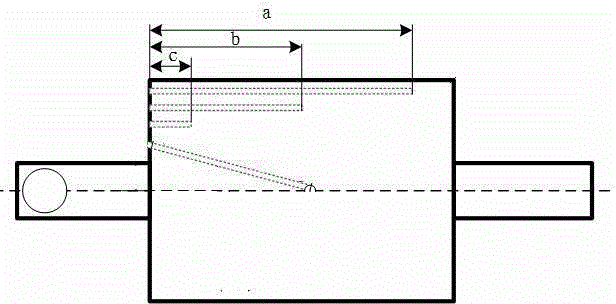

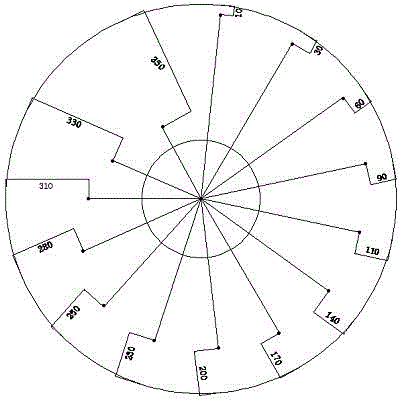

[0020] Such as figure 1 , figure 2 Shown: the present invention relates to a kind of method for measuring the depth of hardened layer of roll body, comprising the following steps:

[0021] 1) Selection of test rolls used for testing

[0022] Choose ordinary 20# steel rolls for temperature measurement test. According to the data obtained in low carbon steel, the data corresponding to the commonly used materials of rolls can be obtained; among them: the diameter of the temperature measuring roll body is 1000mm, the length of the roll body is 1500mm, and the size of the temperature measuring hole The diameter is 8mm, and the roll neck radius is 240mm, so that more temperature measurement data in the radial direction of the roll body can be obtained.

[0023] 2) Processing of temperature measuring hole

[0024] (1) Arrangement of the base point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com