Double-cylinder synchronous hydraulic circuit with functions of supercharging and eliminating accumulated error

A technology of accumulative error and hydraulic circuit, which is applied in the direction of fluid pressure actuators, servo motors, mechanical equipment, etc., can solve the problems of poor synchronization accuracy of two oil cylinders, and achieve a high degree of synchronization, strong synchronization ability, and high degree of synchronous motion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

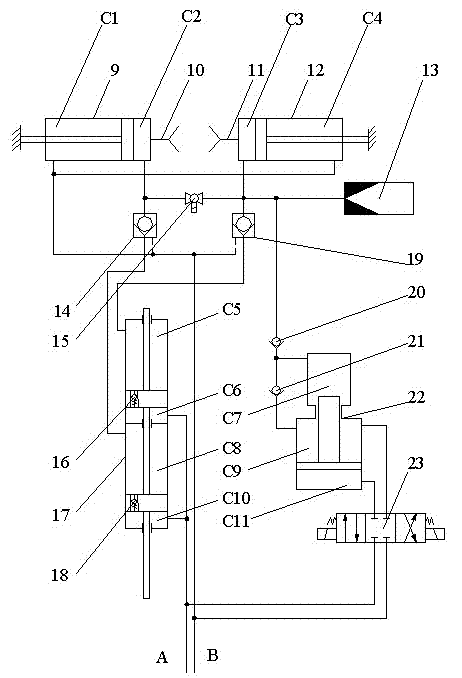

[0013] The present invention as image 3 As shown, a dual-cylinder synchronous hydraulic circuit with the functions of boosting and eliminating accumulated errors includes a left cylinder 9, a right cylinder 12, a left oil circuit A, and a right oil circuit B; the rod cavity C1 of the left cylinder 9 and the right cylinder The rod cavity C4 of 12 is connected in parallel and then divided into three circuits, one of which is connected to the right oil circuit B, and the other two channels are respectively connected to the control oil ports of the hydraulic control check valves 14 and 19 through the control oil circuit; the rodless chamber C2 of the left cylinder 9 The set hydraulic control check valve 14 is connected to the lower upper cavity C8 of the synchronous cylinder 17; the rodless cavity C3 of the right cylinder 12 is connected to the upper cavity C5 of the synchronous cylinder 17 through the set hydraulic control check valve 19; The lower chamber C6 and the lower lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com