Pressurizer for mechanical seal

A technology of mechanical seals and pressure-holding devices, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of sealing oil ingress, polymerization tank pollution, etc., achieve long service life, low cost, and ensure the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

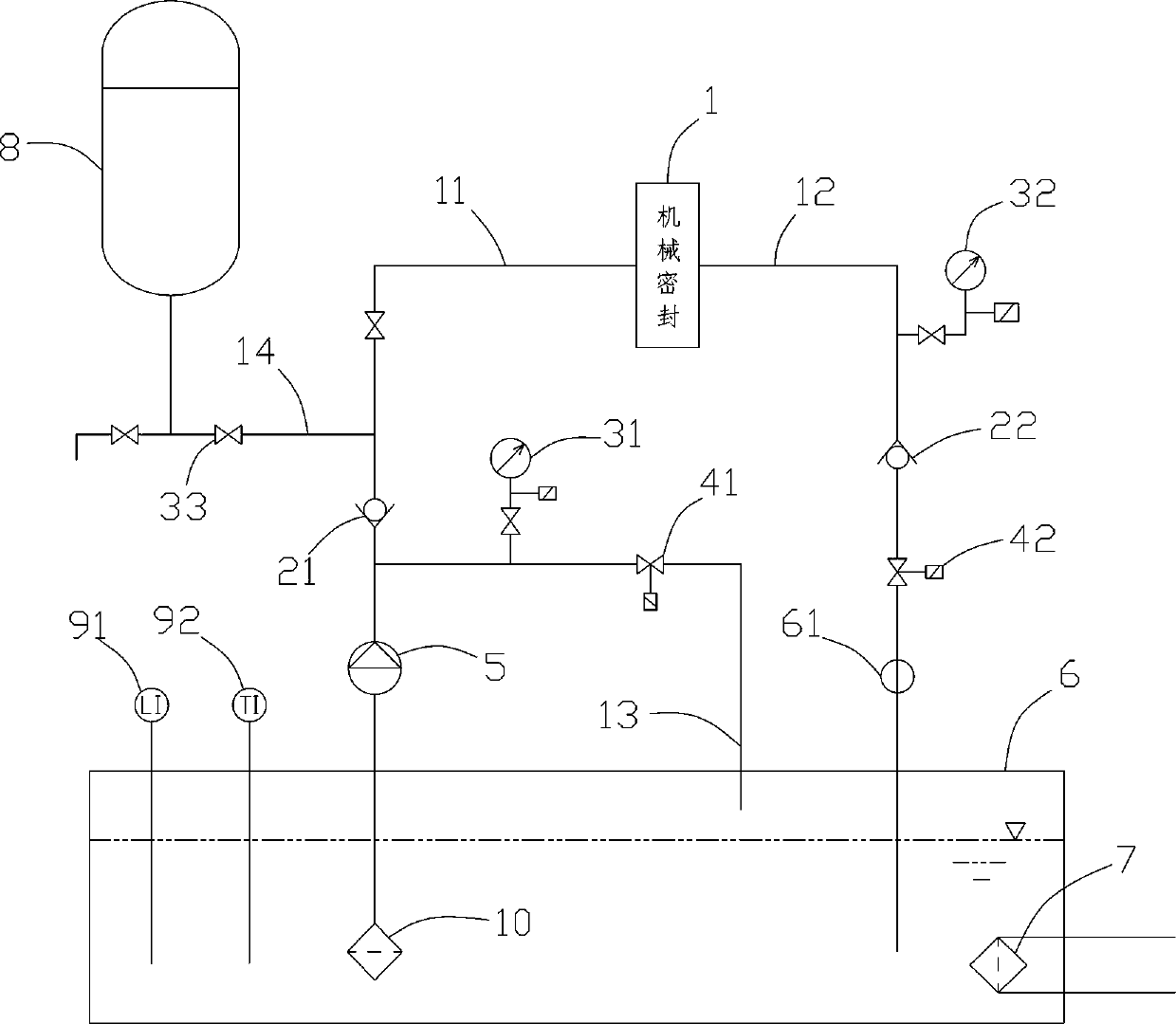

[0018] Such as figure 1 As shown, a mechanical seal pressure maintaining device includes a water tank 6. Soft water without precipitation and impurities is used in the water tank 6. The temperature is normal temperature, and the water needs to be replaced regularly. The water inlet and outlet of the mechanical seal 1 pass through the water inlet pipe 11 and The return pipe 12 is connected to both ends of the water tank 6, and a cooler 7 is installed in the water tank 6 close to the end of the return pipe 12. The cooler 7 can use circulating water as the cooling medium to cool the heat generated during the operation of the mechanical seal 1. A first one-way valve 21 , a water pump 5 and a filter are installed, and a second one-way valve 22 is installed on the return pipe 12 .

[0019] The use method of the present invention: start the water pump 5, the pressure of the water pump 5 will automatically open the first one-way valve 21, the demineralized water will fill the sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com