An automatic drainage device for a rail vehicle box body

A technology for automatic drainage and rail vehicles, which is applied in the direction of valve devices, valve operation/release devices, sliding valves, etc., which can solve problems such as safety hazards and slow drainage effects, so as to improve operational safety performance, ensure sealing, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention, and the technical solution of the present invention is further described in conjunction with the accompanying drawings.

[0031] The drainage device is installed at the bottom of the auxiliary power box under the vehicle, and can be connected with the box by means of fasteners or welding as required.

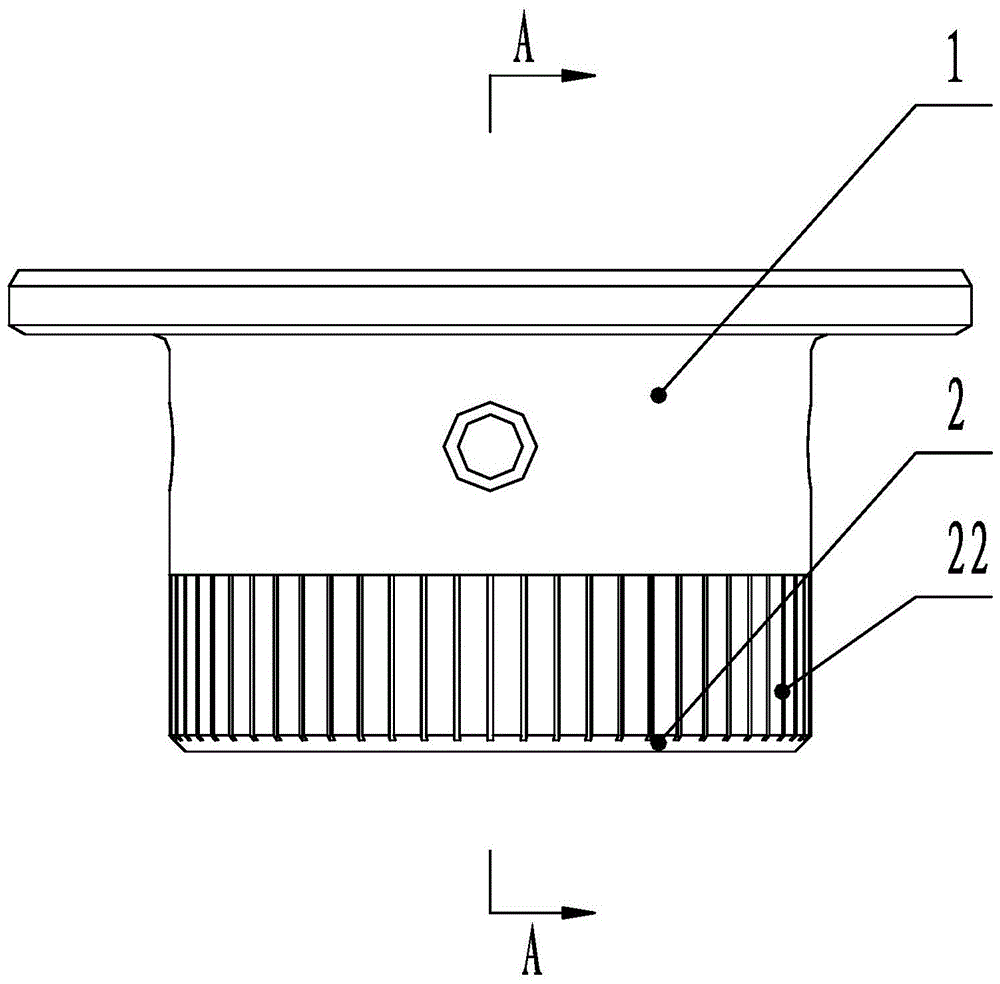

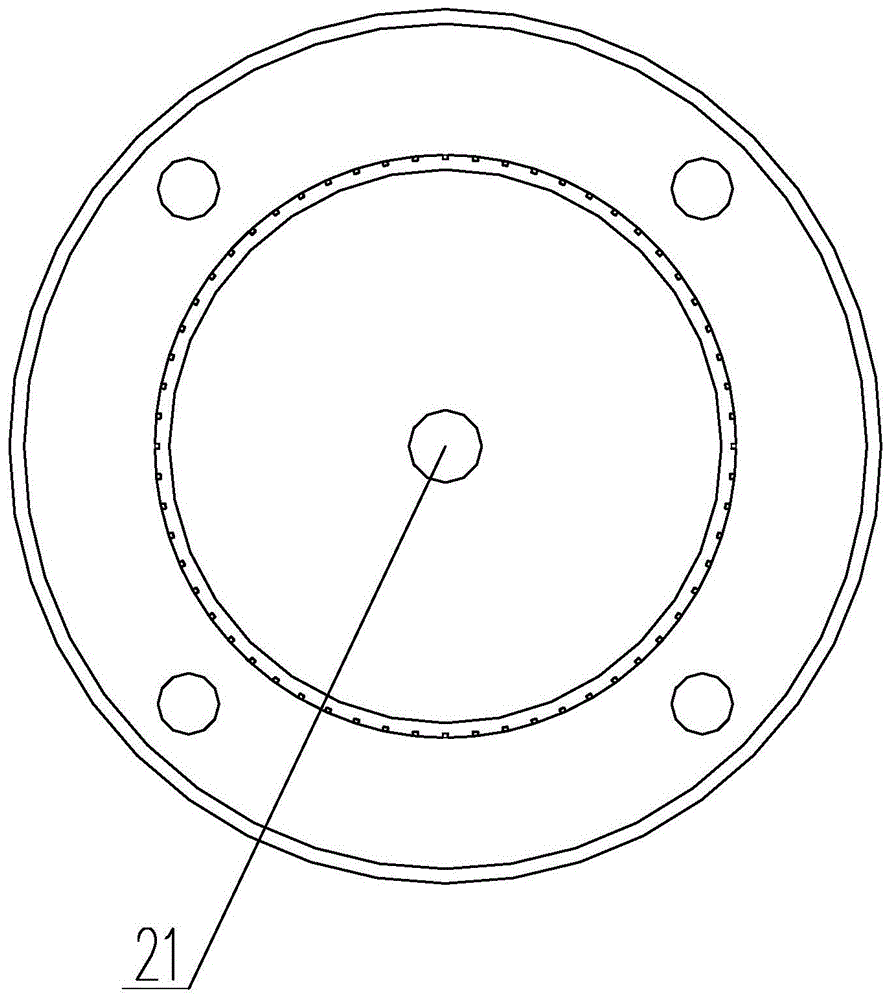

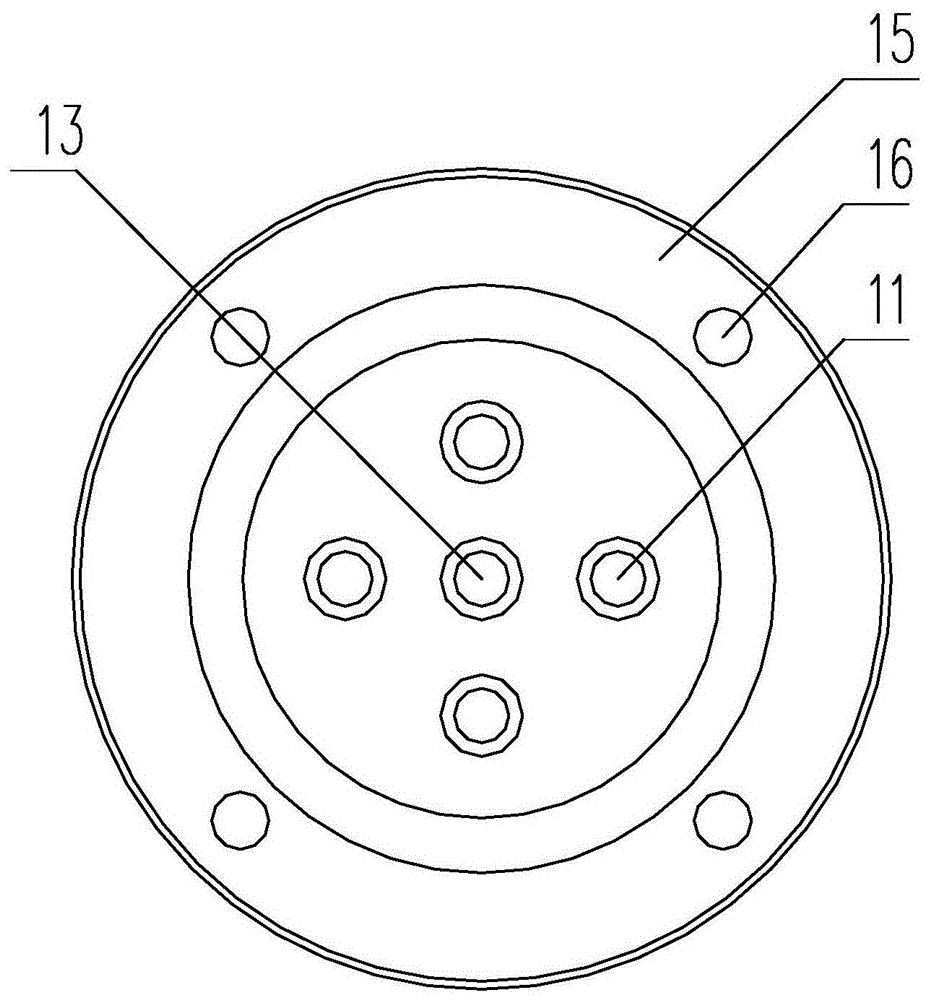

[0032] Such as Figure 1 to Figure 7 An automatic drainage device for a rail vehicle box shown includes a valve seat 1, a plug cover 2, a piston 4, and a compression spring 5, and also includes a water expansion block 3. The valve seat includes a pair of drain holes 11, The upper installation cavity 12 of the water expansion block, the water absorption hole 13 of the water expansion block and a pair of outer drain holes 14 of the valve seat. The piston 4 is in clearance fit with the inner cavity of the valve seat 1, and the piston 4 is provided with a lower installation cavity for the water expansion block 41. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com