Production method of high magnetic induction oriented silicon steel

A technology of high magnetic induction orientation and production method, which is applied in the production field of high magnetic induction oriented silicon steel, can solve the problems of fluctuation of magnetic properties, increased control difficulty, insufficient inhibitor concentration, etc., and achieves improved magnetic properties, enhanced inhibitor concentration, Perfect the effect of secondary recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

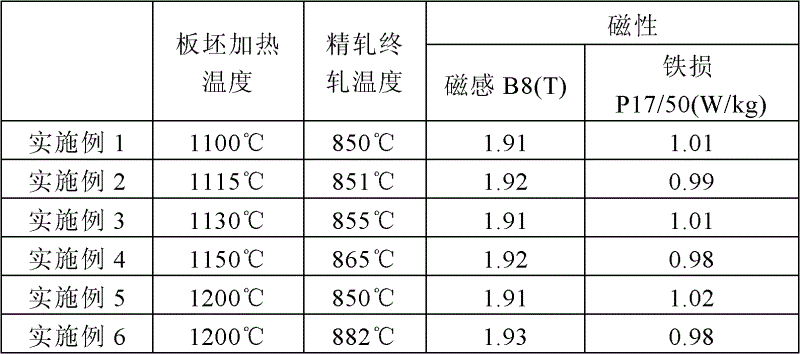

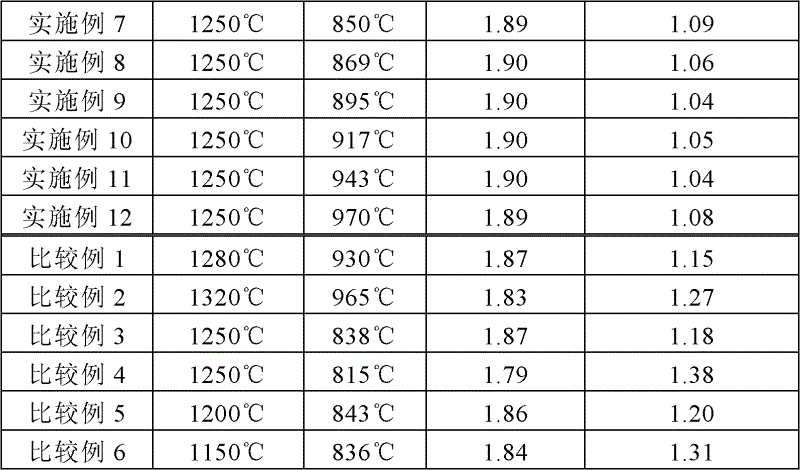

[0034] The components and weight percentages of oriented silicon steel slabs are C: 0.062%, Si: 3.3%, Als: 0.024%, N: 0.007%, S: 0.013%, Mn: 0.15%, Cu: 0.15%, and the rest are Fe and unavoidable impurities. The slab is hot-rolled to a hot-rolled plate with a thickness of 2.3 mm after being kept in the heating furnace for 2 hours according to the different slab heating temperatures in Table 1. The final rolling temperature of the hot-rolled finish rolling refers to Table 1; Cold rolling, after rolling to a finished product thickness of 0.30mm, decarburization annealing is carried out at a decarburization temperature of 800-880°C and a wet hydrogen protection atmosphere, so that the carbon content in the steel plate is reduced to below 30ppm; the isolation of coated magnesium oxide as the main component After coiling, perform high-temperature annealing at 1200°C for 20 hours; perform nitriding treatment after final cold rolling and before high-temperature annealing and secondary...

Embodiment 2

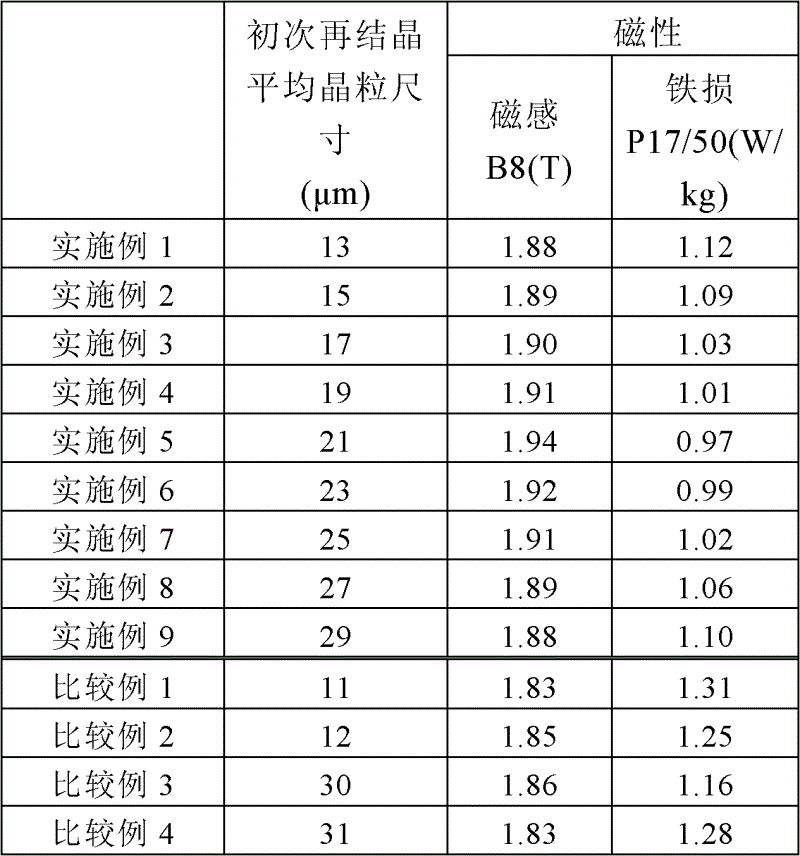

[0039] The components and weight percentages of oriented silicon steel slabs are C: 0.067%, Si: 3.5%, Als: 0.028%, N: 0.010%, S: 0.018%, Mn: 0.12%, Cu: 0.22%, and the rest are Fe and unavoidable impurities. Heat the slab in a heating furnace at 1200°C for 3 hours, and then hot-roll it to a hot-rolled plate with a thickness of 2.8mm. After the thickness is reached, intermediate decarburization annealing is carried out at a decarburization temperature of 800-880°C in a wet hydrogen protective atmosphere to reduce the carbon content in the steel plate to below 30ppm. By adjusting the decarburization annealing process, the steel plate after decarburization annealing can obtain different initial The average grain size of recrystallization; after coating the release agent with magnesium oxide as the main component, high temperature annealing is carried out, and nitriding treatment is carried out after the final cold rolling and before high temperature annealing and secondary recryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com