Method for breeding and separating high arsenic oxidizing bacteria

A high-arsenic oxidizing bacteria and separation method technology, which is applied in the field of leaching bacteria for efficiently oxidizing arsenic-containing sulfide ores, especially arsenic pyrite, can solve the problems of lack of arsenic-resistant bacteria, arsenic sand oxidation potential or weak oxidation potential, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

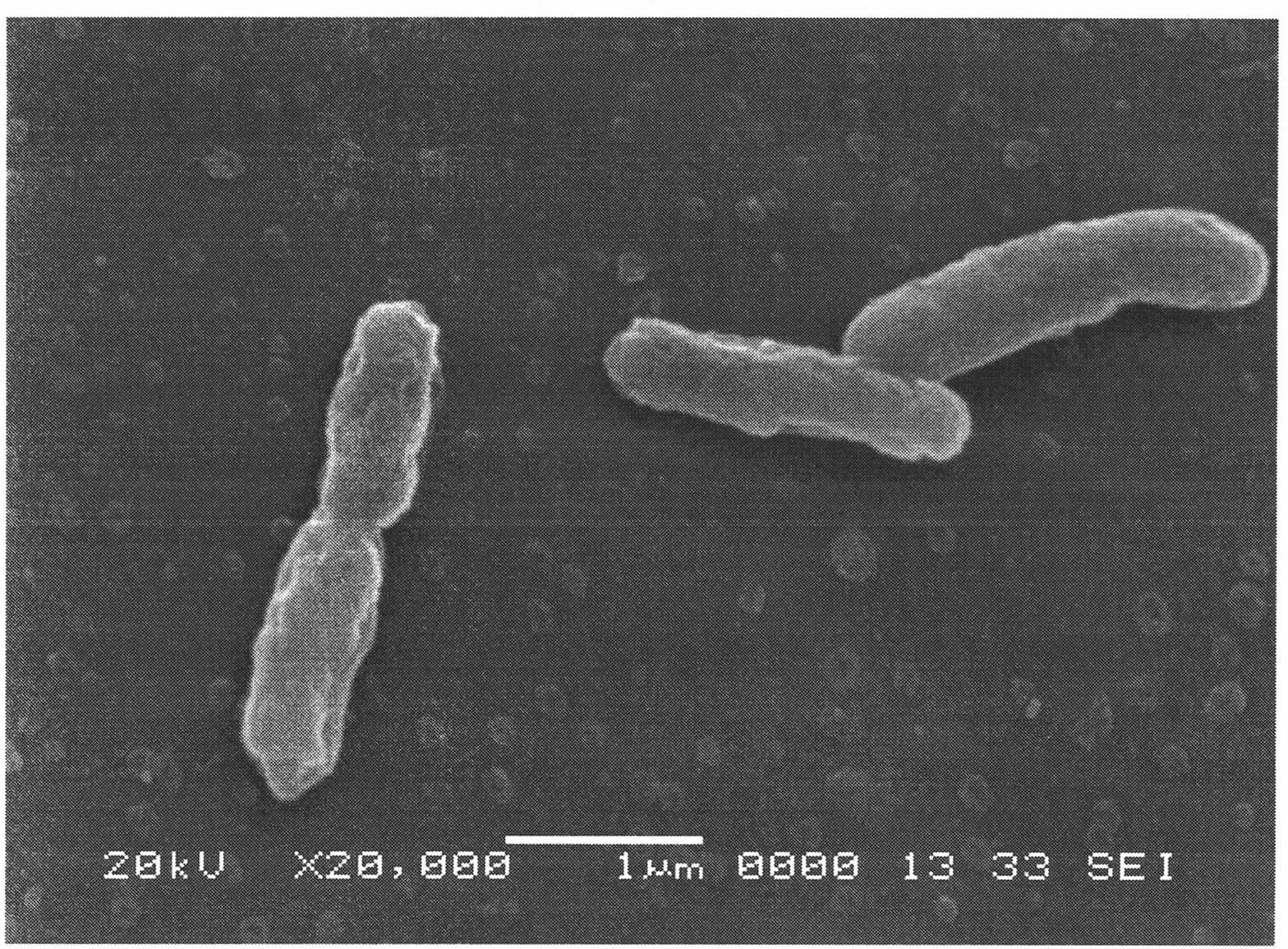

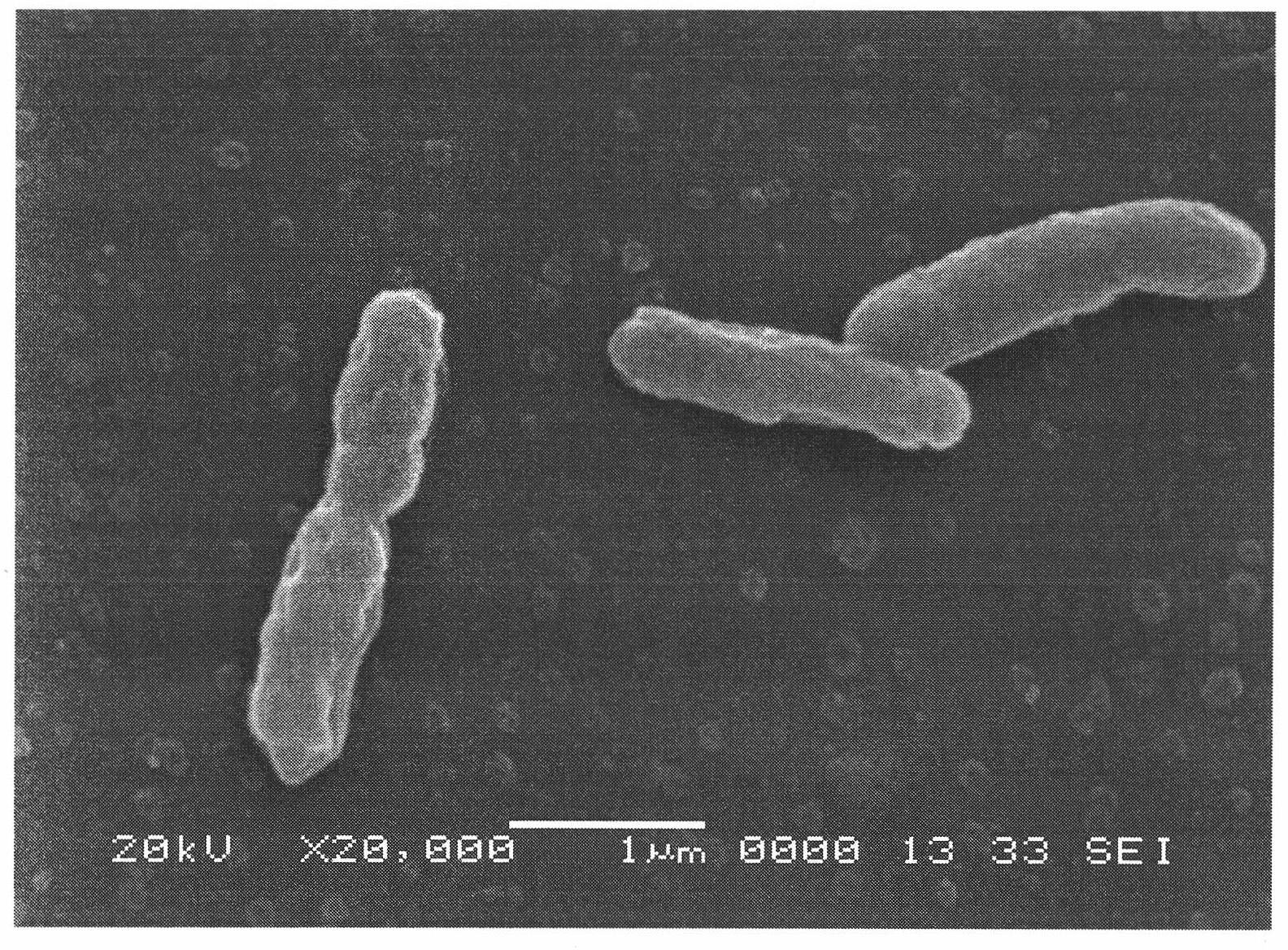

Image

Examples

Embodiment Construction

[0016] Collect tailings samples from the long-term tailings area of high-arsenic gold mines and high-arsenic gold concentrate warehouse drainage ditch mud samples, mix the samples in equal amounts, add 2 times the volume of dilute sulfuric acid aqueous solution (pH2.0), slowly stir and mix, Make a suspension.

[0017] Take a sterilized 250mL Erlenmeyer flask, add 150mL medium 1, insert the above sample suspension according to the inoculum amount of 5%, adjust the pH to 2.0 with dilute sulfuric acid, shake and cultivate at 30°C, and regularly test the culture medium Fe 2+ , when Fe 2+ When the oxidation rate reaches over 95%, re-add FeSO to the culture medium according to the formula ratio 4 ·7H 2 O, and make up the culture solution to the original volume (150mL) with sterilized water, and continue shaking culture for 10 days, which is the first generation enrichment.

[0018] The first-generation enrichment was transferred to 150mL medium 2 at an inoculum amount of 2%, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com