Nanometer composite porous gel microsphere and preparation method thereof

A nanocomposite and microsphere technology, which is applied in the preparation of microspheres, microcapsule preparations, pharmaceutical formulations, etc., can solve the problems of difficult removal and cumbersome process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

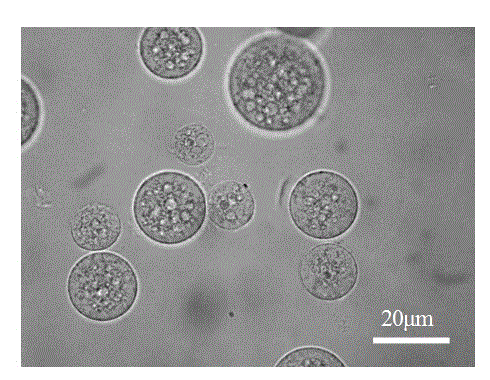

[0024] Dissolve 200mg of monomer Am, 20mg of cross-linking agent BIS, and 10mg of initiator V-50 in 2mL of water, and ultrasonically disperse 20mg of clay particles in this solution, add 11mg of sodium chloride to form an aqueous phase solution. Mix 1 mL of toluene and aqueous phase solution to prepare O / W colostrum by ultrasonic emulsification. 2mL colostrum was added to 8mL containing 40mg SiO 2 In the toluene of the particles, the colostrum was re-emulsified by hand shaking to prepare an O / W / O emulsion. Next, the multiple Pickering emulsion prepared by the two-step method was deaerated by Ar gas for 5 minutes, and placed in an ice-water bath with a light intensity of 30mW / cm 2 UV light-induced polymerization. After irradiating for 5 minutes, the distance between the emulsion and the UV lamp is 47cm. The reaction finishes and obtains porous polyacrylamide (PAm) gel microspheres (see figure 1 ).

Embodiment 2

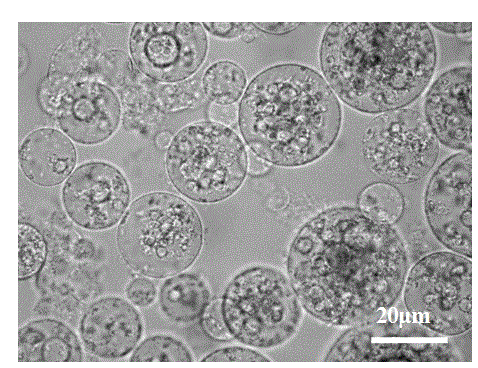

[0026] Dissolve 200mg of monomer NIPAm, 20mg of cross-linking agent BIS, and 10mg of initiator V-50 in 2mL of water, and ultrasonically disperse 20mg of clay particles in this solution, add 11mg of NaCl to form an aqueous phase solution. O / W colostrum was prepared by ultrasonic emulsification by mixing 0.5 mL of toluene and aqueous phase solution. 2mL colostrum was added to 8mL containing 40mg SiO 2 In the toluene of the particles, the colostrum was re-emulsified by hand shaking to prepare an O / W / O emulsion. Next, the multiple Pickering emulsion prepared by the two-step method was passed through Ar gas for 5 minutes to remove oxygen, and then placed in an ice-water bath to initiate polymerization with ultraviolet light with a light intensity of 30 mW / cm2. After irradiating for 5 minutes, the distance between the emulsion and the UV lamp is 47cm. The end of the reaction obtains the multicavity PNIPAm gel microspheres (see Figure 2a ).

Embodiment 3

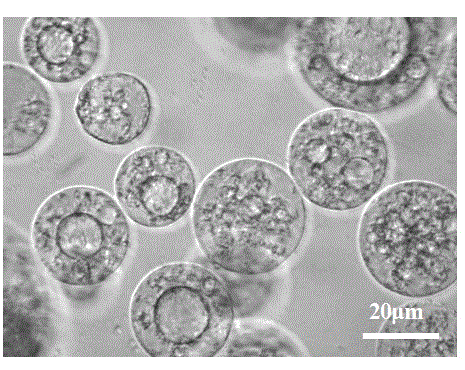

[0028] Dissolve 200mg of monomer NIPAm, 20mg of cross-linking agent BIS, and 10mg of initiator KPS in 2mL of water, and ultrasonically disperse 20mg of clay particles in the solution, add 11mg of sodium chloride to form an aqueous solution. Mix 0.5 mL of xylene and aqueous phase solution to prepare O / W colostrum by ultrasonic emulsification. 2mL colostrum was added to 8mL containing 40mg SiO 2 In the toluene of the particles, the colostrum was re-emulsified by hand shaking to prepare an O / W / O emulsion. Next, the multiple Pickering emulsion prepared by the two-step method was passed through Ar gas for 5 minutes to remove oxygen, and placed in an oven at 70° C. for 12 hours. The end of the reaction obtains the multicavity PNIPAm gel microspheres (see Figure 2b ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com