Wastewater-free preparation method of bentazon

A bentazon and waste water-free technology, applied in the chemical industry, can solve the problems of waste water polluting the environment, and achieve the effects of high product purity, high yield, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

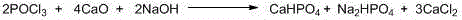

Image

Examples

Embodiment 1

[0027] Dissolve 16.3 g of isatoic anhydride in 50 mL of N,N-dimethylformamide and heat to 50 o C. Dissolve 6.8 g of isopropylamine in 25 mL of N,N-dimethylformamide, drop it into the above solution, and drop it at 50 o The reaction was continued for 30 minutes at C to obtain a transparent homogeneous solution, and the solvent was evaporated under reduced pressure, and dried to obtain anthranilamide, hereinafter referred to as "amide", with a yield greater than 99% and a purity greater than 97%, which was directly used in the following Step reaction;

[0028] Dissolve 10.7 g of 2-picoline in 50 mL of dichloroethane and cool to 0 o C, at 0 o Chlorosulfonic acid was added dropwise under the condition of C to obtain a double salt; the amide obtained above was dispersed with 50 mL of dichloroethane and heated to 50 oC ; quickly mix the double salt with the amide dispersed with dichloroethane, at 50 o C was reacted for 3 hours, TLC detected that after the amide reaction was com...

Embodiment 2

[0033] Dissolve 16.3 g of isatoic anhydride in 50 mL of acetonitrile and heat to 50 o C. Dissolve 6.8 g of isopropylamine in 25 mL of acetonitrile, drop it into the above solution, and drop it at 50 o The reaction was continued for 40 minutes under C to obtain a transparent homogeneous solution, and the solvent was evaporated under reduced pressure, and dried to obtain anthranilamide, the productive rate was 99%, and the purity was 95%;

[0034] The following is the same as Example 1, except that the feed ratio of the whole process is: in molar ratio, isatoic anhydride: isopropylamine: chlorosulfonic acid: 2-picoline: phosphorus oxychloride=1: 1: 1.2: 1.2: 1.

Embodiment 3

[0036] Dissolve 16.3 g isatoic anhydride in 50 mL N,N-dimethylacetamide, heat to 60 o C. Dissolve 7.1 g of isopropylamine in 25 mL of N,N-dimethylacetamide, drop it into the above solution, and drop it at 60 o The reaction was continued for 60 minutes under C to obtain a transparent homogeneous solution, and the solvent was evaporated under reduced pressure, and dried to obtain anthranilamide, the productive rate was 99%, and the purity was 97%.

[0037] Below with embodiment 1, difference is that whole process feed ratio is: by molar ratio, isatoic anhydride: isopropylamine: chlorosulfonic acid: 2-picoline: phosphorus oxychloride=1: 1.2: 1.1: 1.1: 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com