Structure and method for detecting whether narrow trench isolation grooves are etched to oxide layers based on silicon-on-insulator (SOI) silicon chip

A trench isolation and oxide layer technology, applied in the field of micro-optical electromechanical devices, can solve the problems of unstable rate, inability to guarantee the same etching rate, poor repeatability, etc., and achieve the effect of ensuring mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

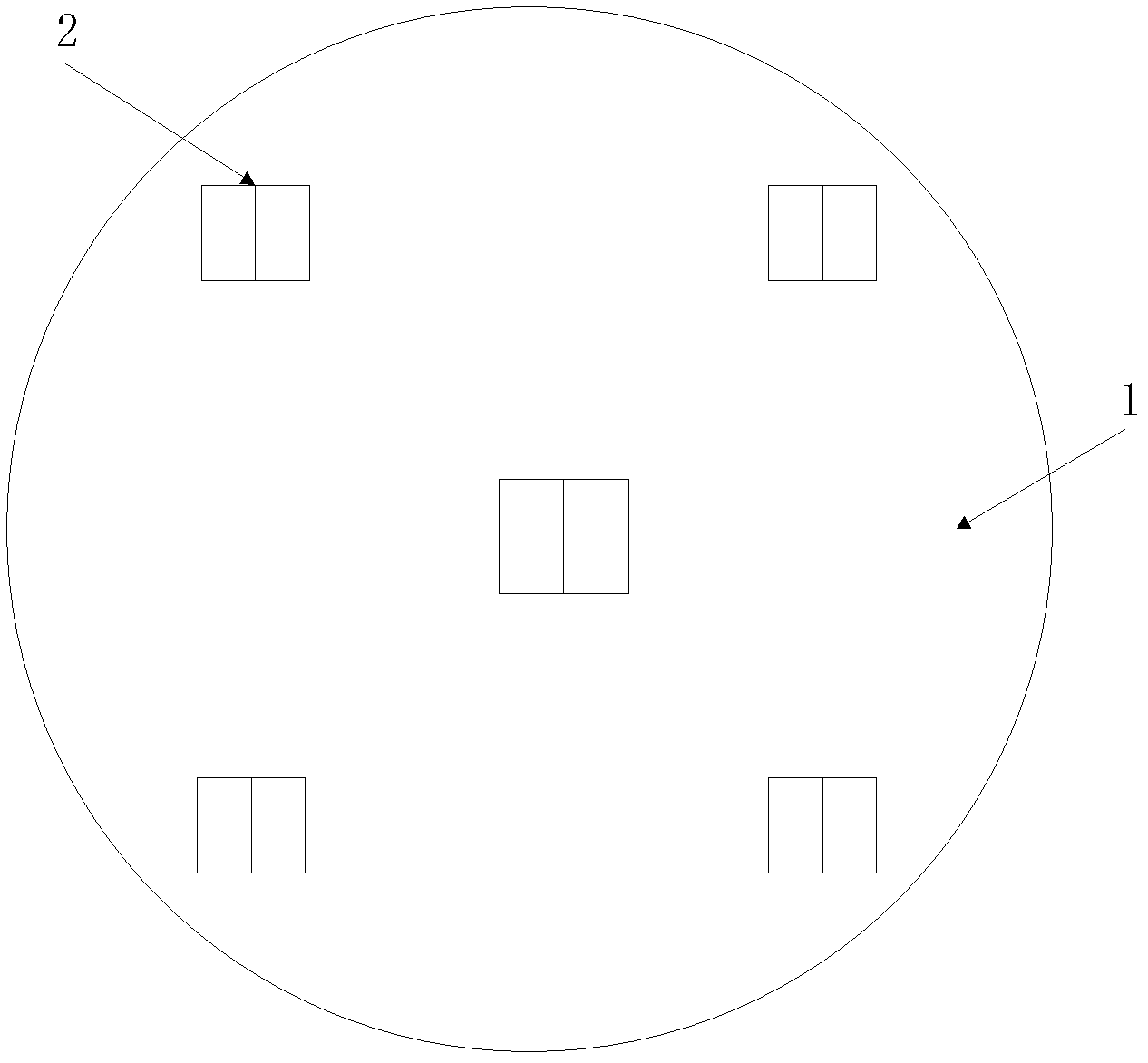

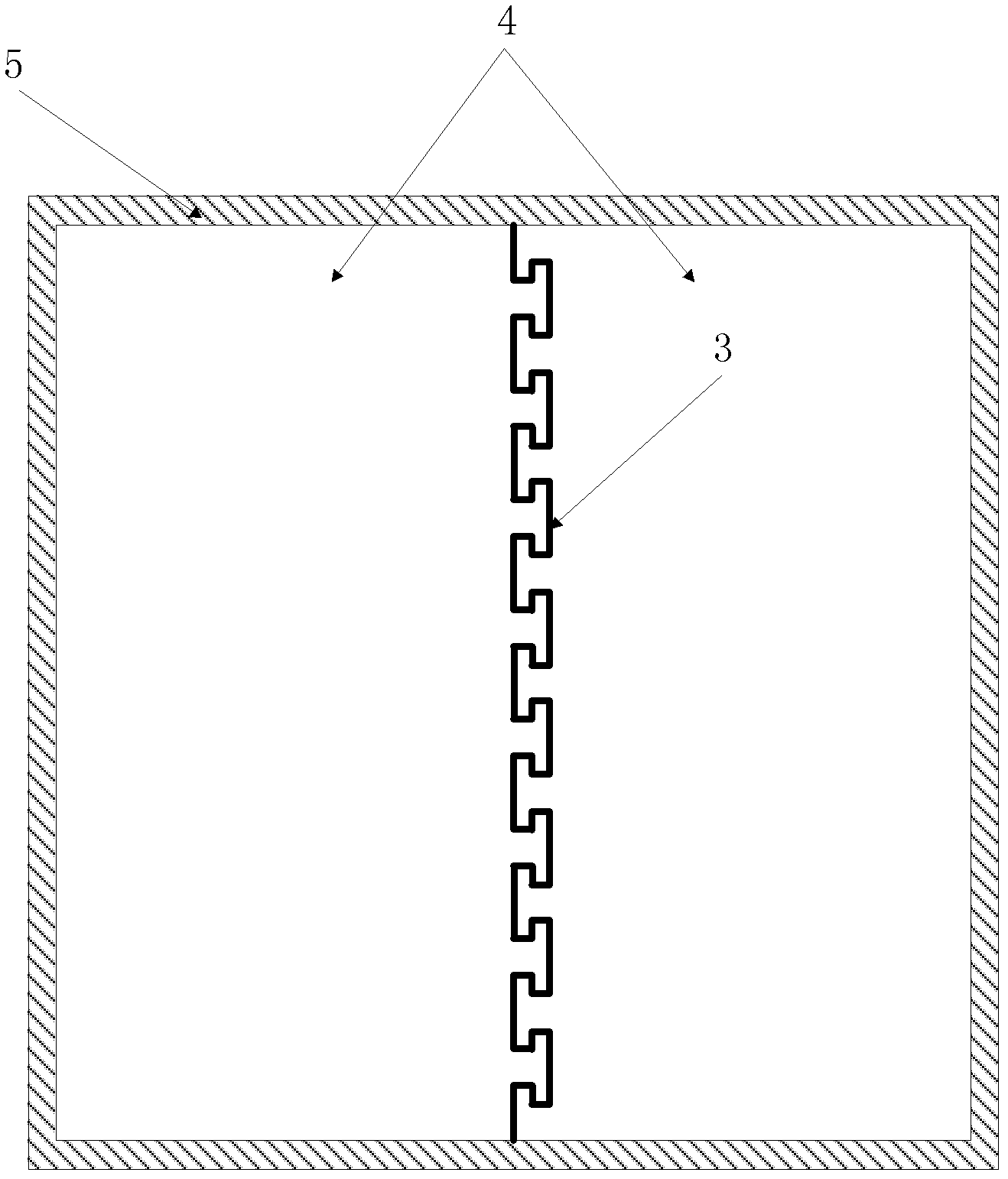

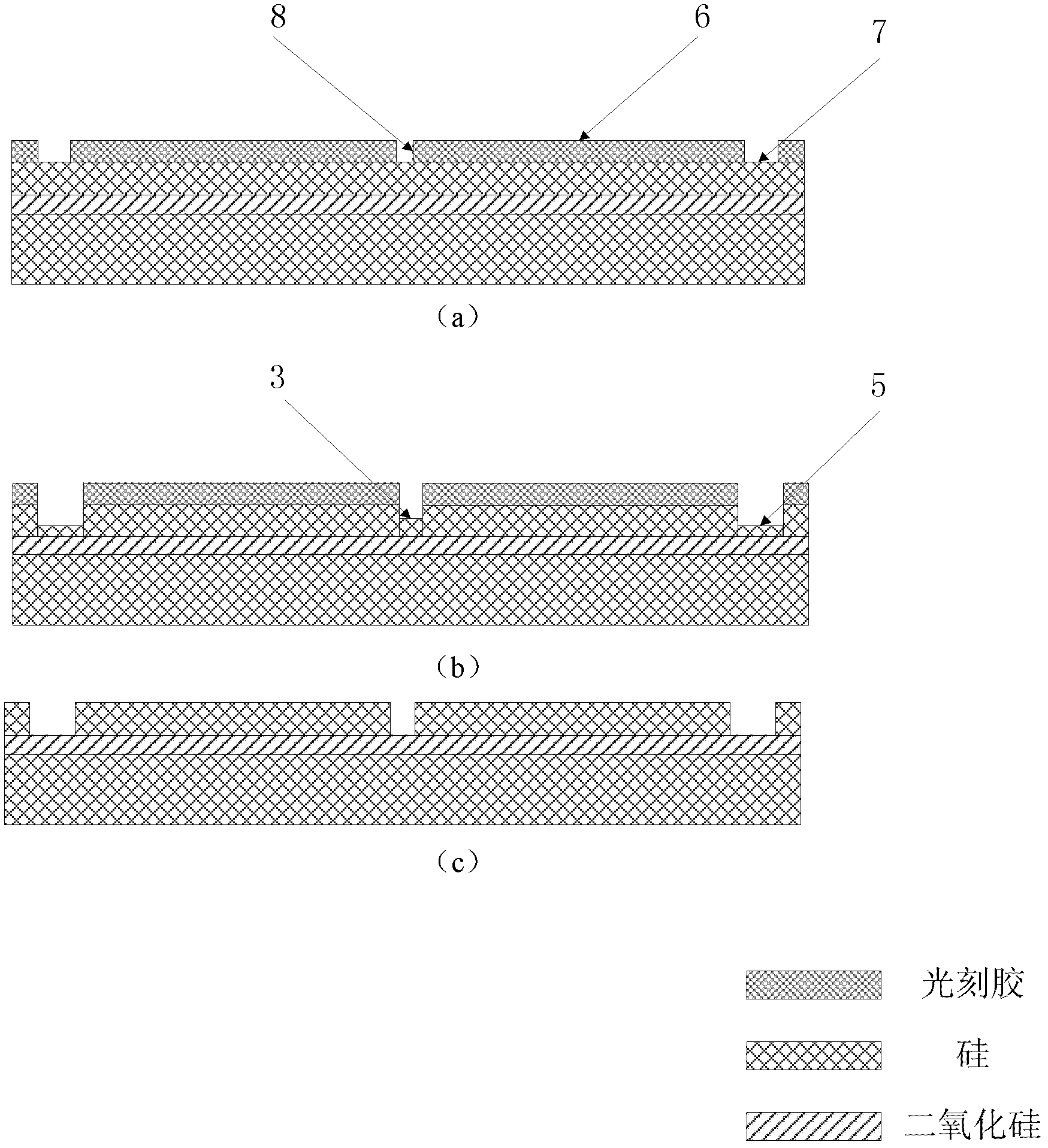

[0023] refer to Figure 5 , this embodiment is a torsion mirror. In the two-dimensional scanning mirror driven electrostatically by the vertical comb teeth, it is necessary to apply voltages to the anchor points of the inner mirror surface and the outer frame to drive the mirror surface and the outer frame to make corresponding twists, but The anchor point of the inner mirror is connected to the outer frame, so that the inner mirror cannot generate a potential difference to make it twist. The trench isolation trench 10 can be used to isolate the inner mirror surface and the outer frame, and an oxide layer is first grown in the etched trench isolation trench as an insulating layer of the isolated mirror surface, and then filled with polysilicon to make the isolated mirror surface have a good Mechanical connection, which not only ensures that the inner mirror surface and the outer frame are a mechanical whole, but also realizes electrical isolation. On the twisted mirror of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com