Master-slave hydraulic mechanical arm controller

A hydraulic machinery and controller technology, applied in the field of master-slave hydraulic mechanical arm controllers, can solve problems such as low precision, poor operational flexibility, and difficult control procedures, and achieve high-voltage insulation, stable and reliable performance, and flexible and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

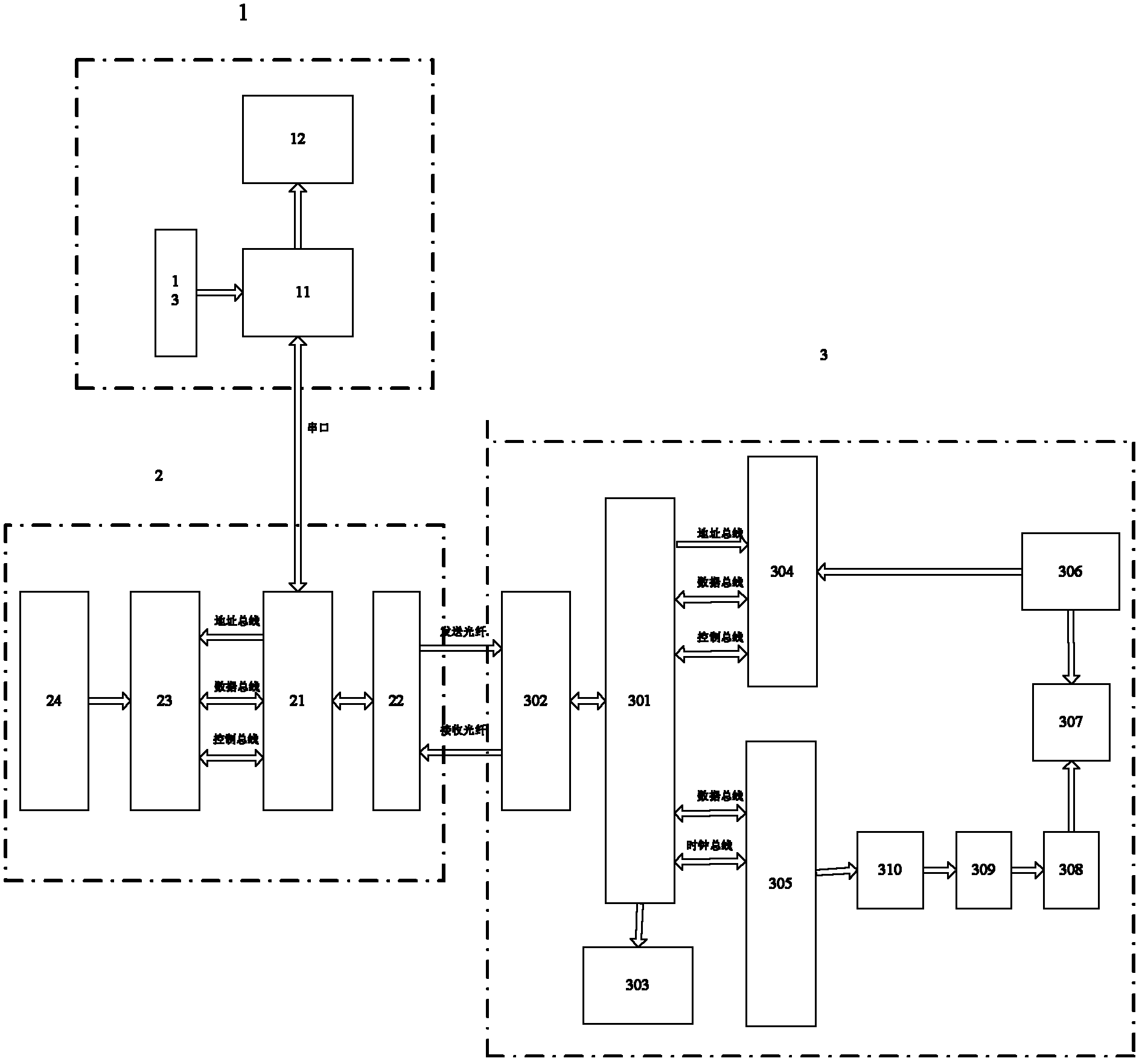

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

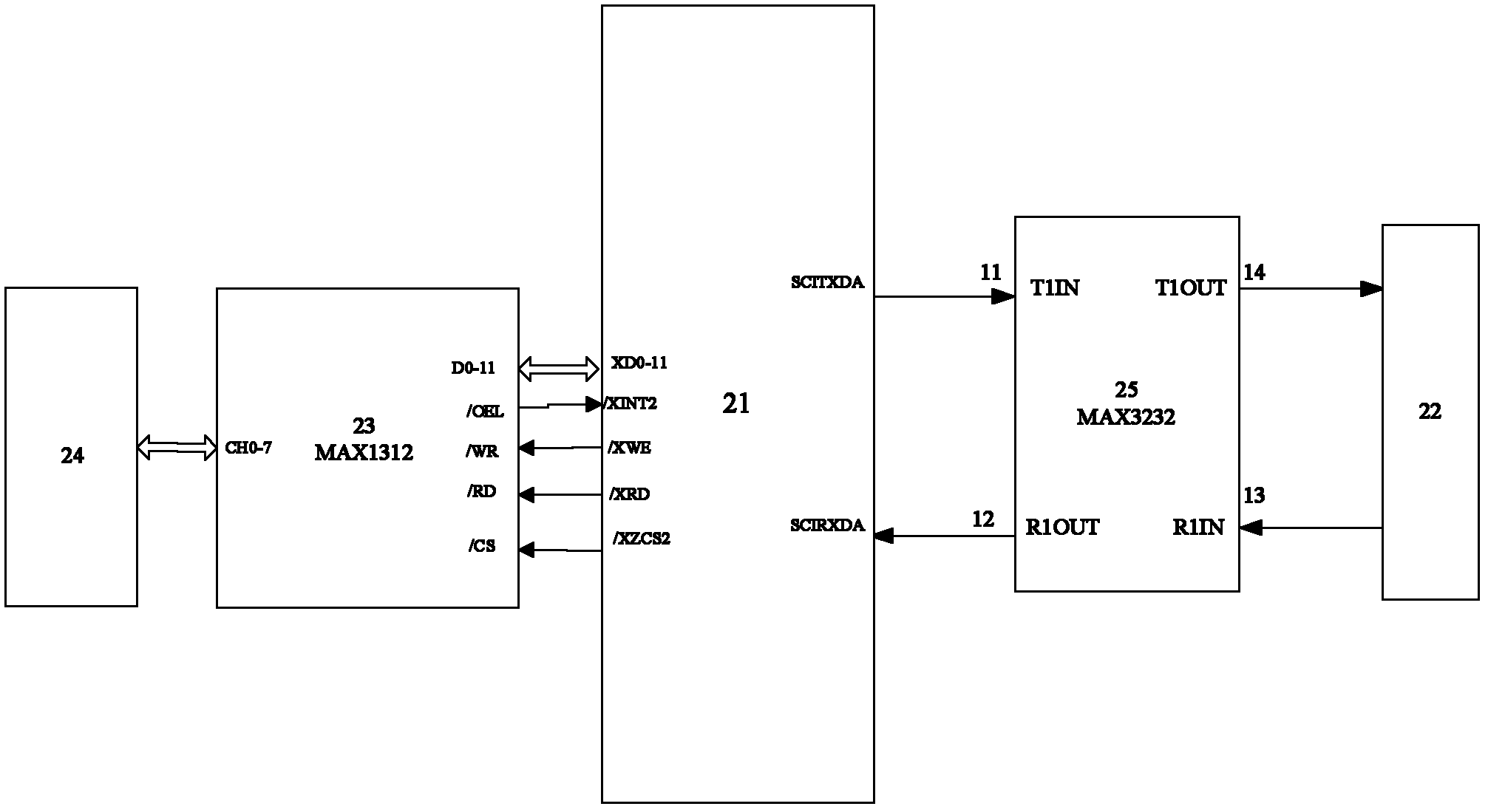

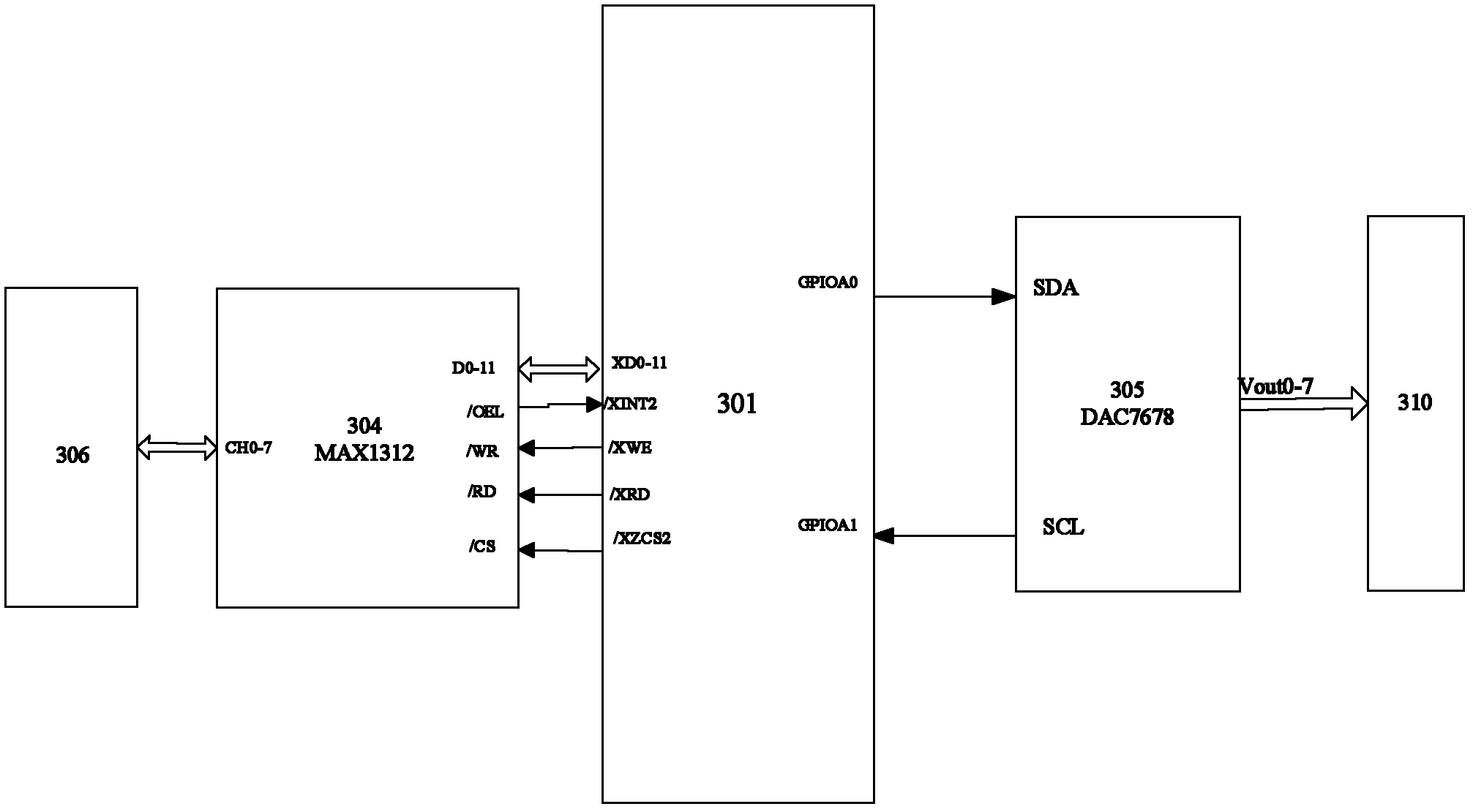

[0033] see figure 1 , a master-slave hydraulic manipulator controller, including a connected hand-held terminal 1, an embedded master hand controller 2 and a manipulator controller 3, the hand-held terminal 1 includes a microprocessor I11, and the microprocessor I11 is respectively Link to each other with the microprocessor II21 of man-machine interface unit and master controller 2; Described master controller 2 comprises microprocessor II21, and microprocessor II21 is connected with A / D converter I23, serial port to optical fiber module 22 respectively; A / D converter I21 is connected with the potentiometer 24 of main hand; Microprocessor III301 of mechanical arm controller 3 is connected with A / D converter II304, D / A converter 305, electromagnetic valve 303 respectively; A / D converter II304 is connected with the potentiometer 306 of the mechanical ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com