Bidirectional rotary electric cutter rest

A tool holder and electric technology, applied in the direction of tool holders, etc., can solve problems such as looseness, loud vibration and noise, and damage to the operator's hearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

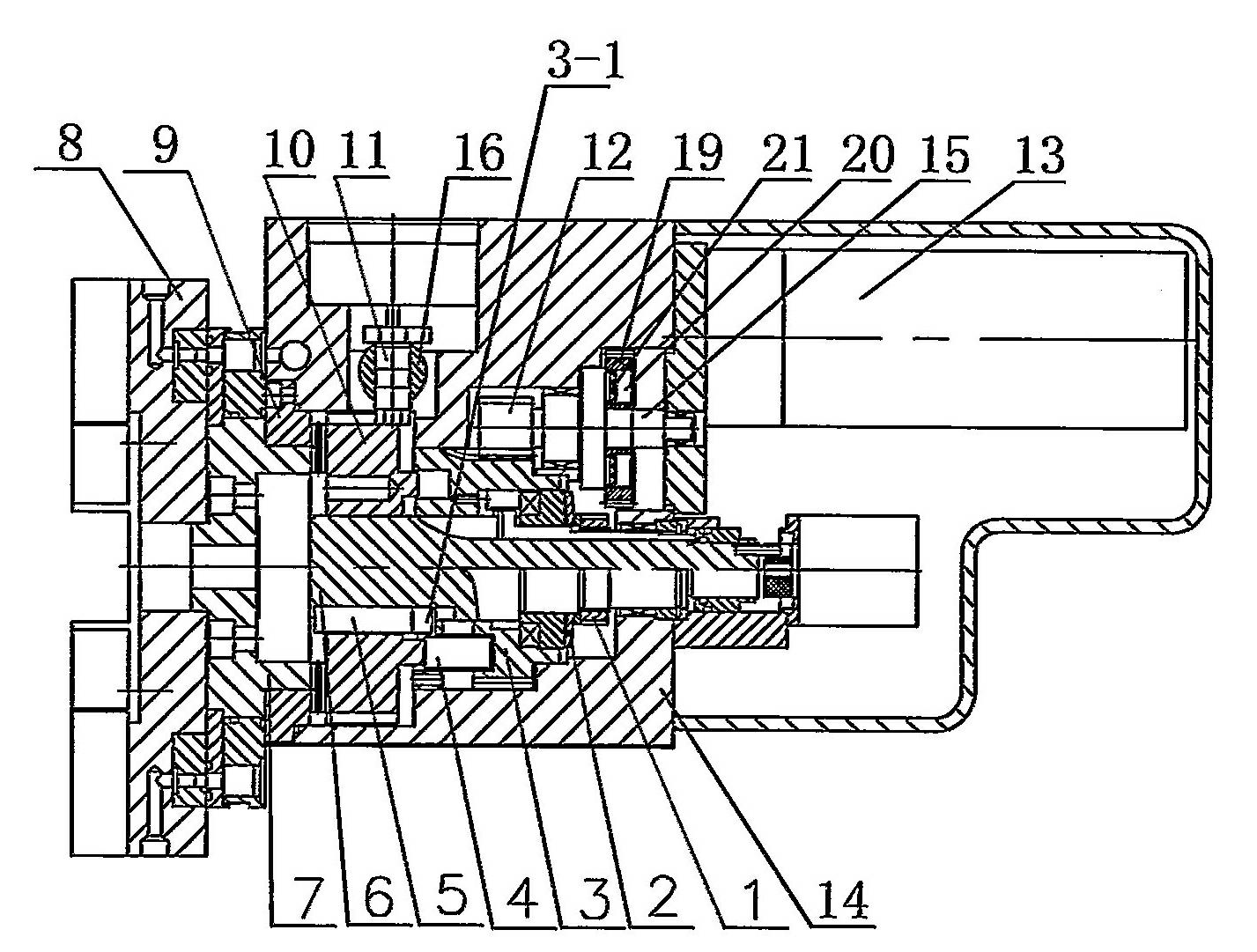

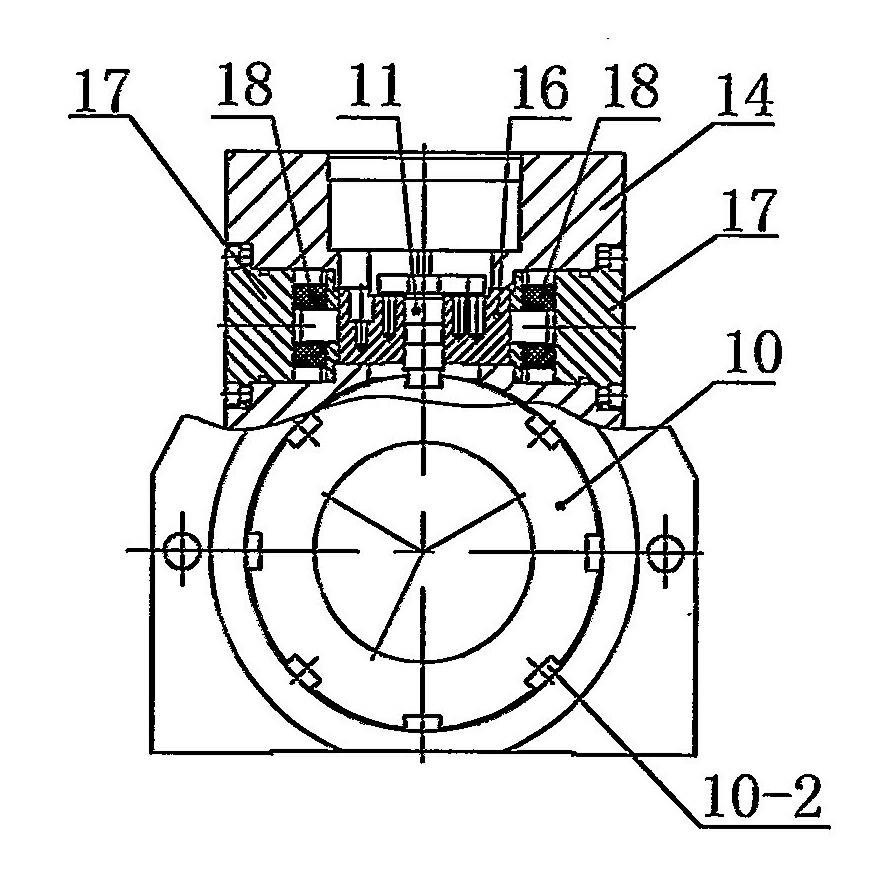

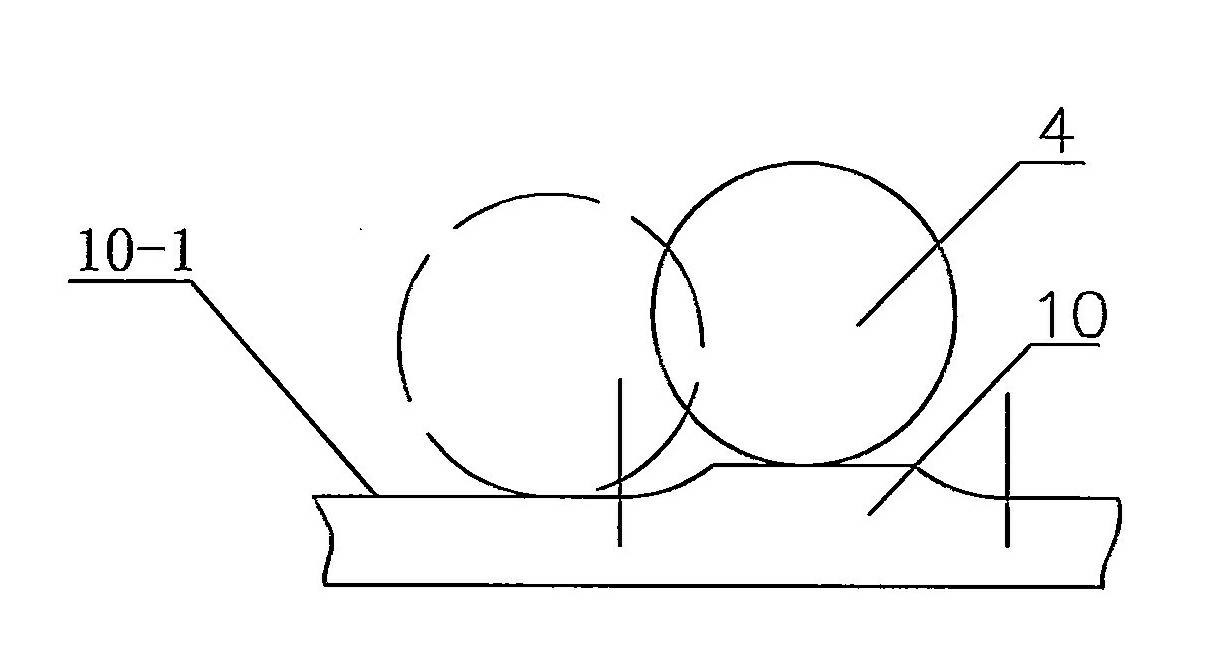

[0012] In order to make the content of the present invention easier to be understood clearly, the following further describes the present invention in detail based on specific embodiments in conjunction with the accompanying drawings.

[0013] Such as Figure 1~3 As shown, a two-way rotary electric tool post includes a box body 14, a cutter head 8, a gear shaft 15, a rotary shaft 6, a roller carrier 3, an outer gear ring 9, an inner gear ring 7 sleeved on the rotary shaft 6 and A motor 13 capable of forward and reverse rotation and a clamping ring gear 10 capable of meshing with the inner gear ring 7 and the outer gear ring 9. The gear shaft 15 is covered with a gear 12, the motor 13 drives the gear shaft 15 to rotate, and the gear 12 and the roller carrier 3 Engaged, the roller carrier 3 is rotatably supported on the rotary shaft 6 through bearings, the clamping gear ring 10 is movably sleeved on the rotary shaft 6 through the key 5, the inner gear ring 7 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com