Ejection mechanism of fixed die push plate

A technology of ejecting mechanism and fixed template, applied in the field of mold accessories, can solve the problems of uneven distribution of ejection force, failure to reach the deformation of ejected products, clamping mold, etc., and achieve the effect of solving unqualified mold products and ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

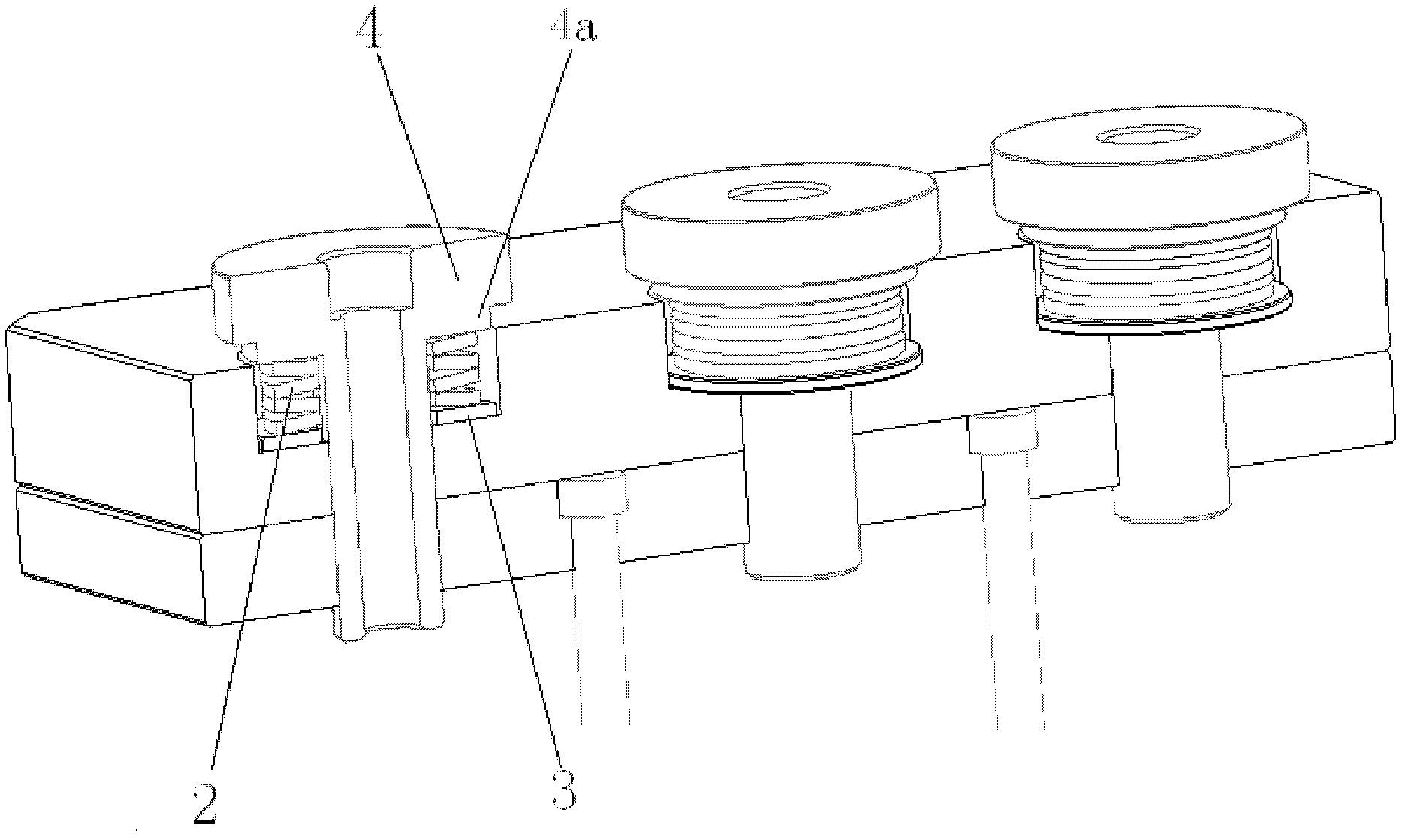

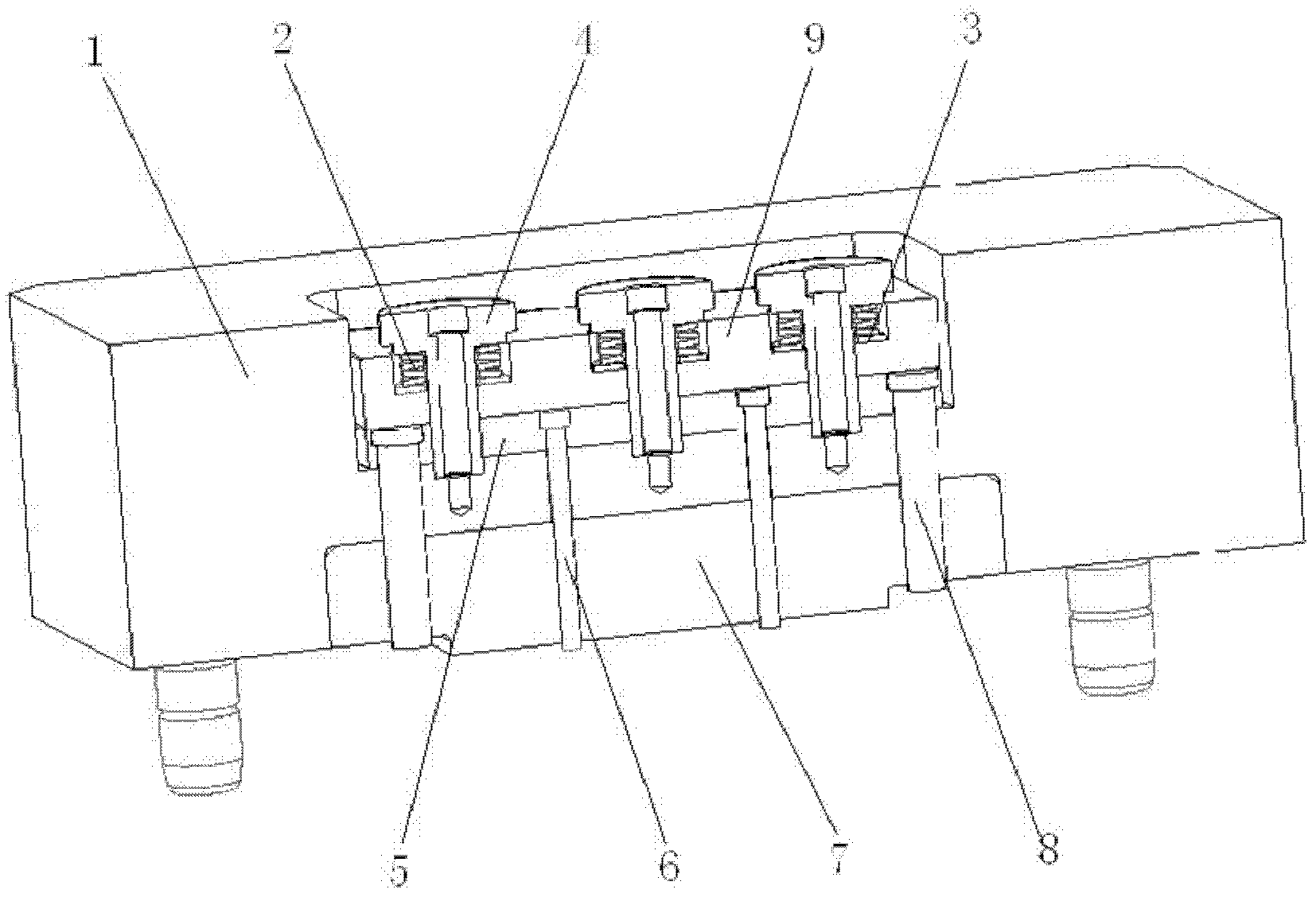

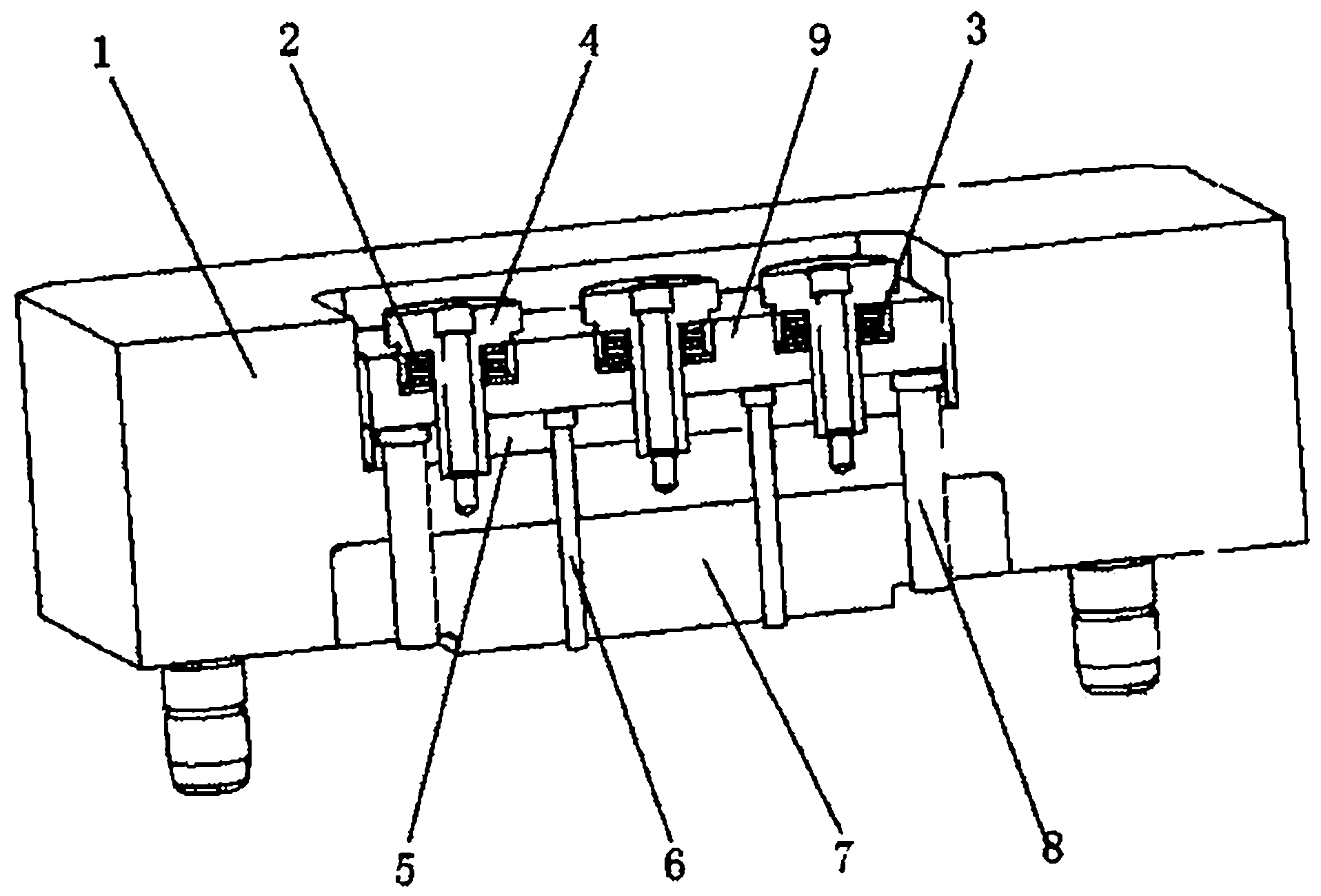

[0015] Such as figure 1 , figure 2 A fixed mold push plate ejection mechanism is shown, including a fixed template 1, a butterfly spring 2, a gasket 3, a guide rod 4, a push rod fixing plate 5, a push rod 6, a fixed inner mold 7, a reset rod 8, a push rod Plate 9, two corresponding mounting grooves are arranged on the upper and lower sides of the fixed template 1, and a push rod fixing plate 5 and a push pedal 9 are installed in the mounting groove above the fixed template 1 from bottom to top; There is a mounting hole, and the mounting hole is T-shaped; on the T-shaped shoulder of the mounting hole, there is a spacer 3 and several disc springs 2 from bottom to top, and a guide rod is set on the spacer 3 and disc spring 2 4. The guide rod 4 is T-shaped and has a threaded hole in the middle. The top surface of the guide rod head 4a is flush with the top surface of the fixed inner mold 7. A small round platform protrudes from the bottom surface of the guide rod head 4a, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com