Centrifugal wind wheel and air treatment device with same

A technology of air treatment device and centrifugal wind wheel, which is applied in the direction of electrostatic separation and external electrostatic separator, which can solve the problems of no dust adsorption and dust removal function, reduced filtration efficiency, frequent replacement, etc., and achieves dust removal efficiency without attenuation , high dust removal efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

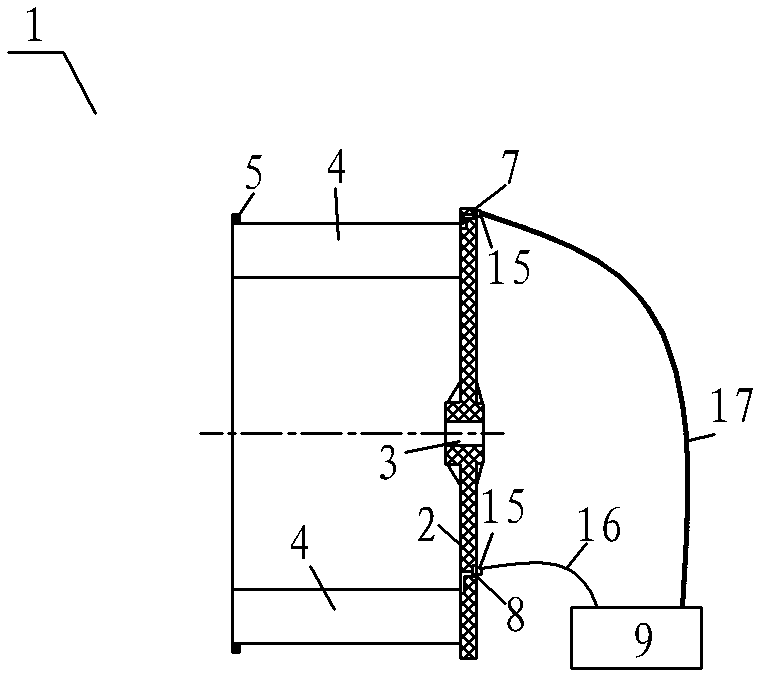

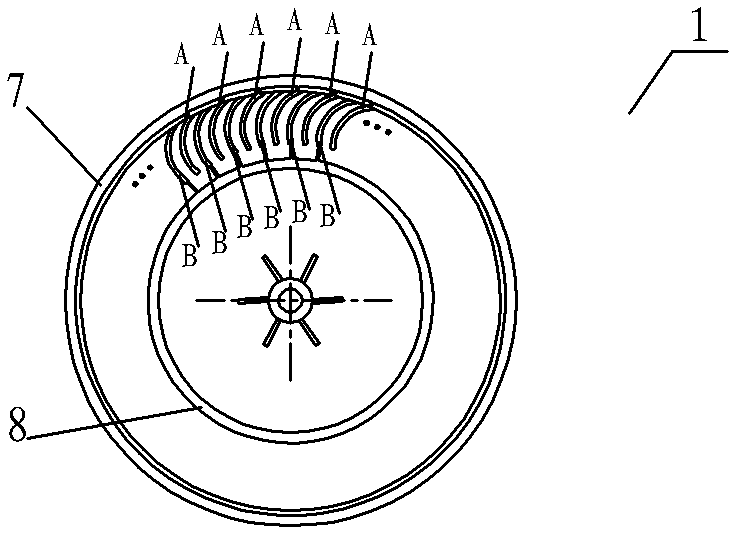

[0067] see Figure 1-Figure 2 , are the front view and the left view of the centrifugal wind rotor 1, respectively. The centrifugal wind wheel 1 includes a chassis 2 , a motor mounting hole 3 , blades 4 , and a reinforcing frame 5 . One end of the blade 4 is distributed on the chassis 2 at a certain interval along the circumferential direction, and the other end of the blade 4 is fixed on the reinforcing frame 5 along the circumferential direction.

[0068] The blades 4 include a first group of blades A and a second group of blades B, the two groups of blades are made of high internal resistance materials and have conductive properties, the first group of blades A and the second group of blades B are distributed alternately, the first The first group of blades A and the second group of blades B are insulated from each other and are not conductive; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com