Continuous crystallizing tank and continuous evaporative crystallization process

A technology of evaporative crystallization and crystallization tank, which is applied in the field of continuous crystallization tank and continuous evaporative crystallization process, which can solve the problems of low production efficiency of monosodium glutamate, poor uniformity of monosodium glutamate particles, and restrictions on product production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Utilize crystallization pot evaporation crystallization monosodium glutamate of the present invention

[0051] 1. Crystallization process

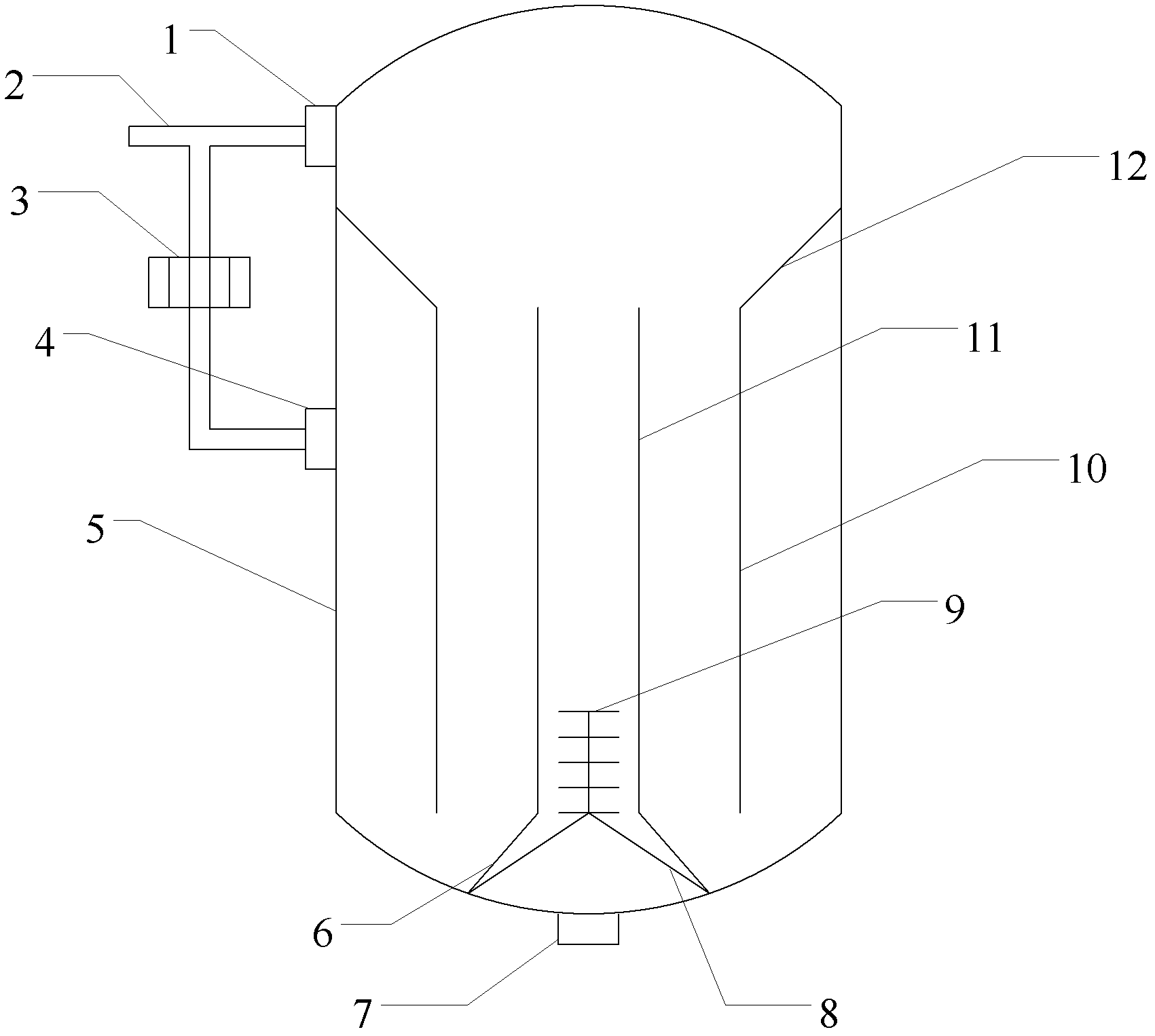

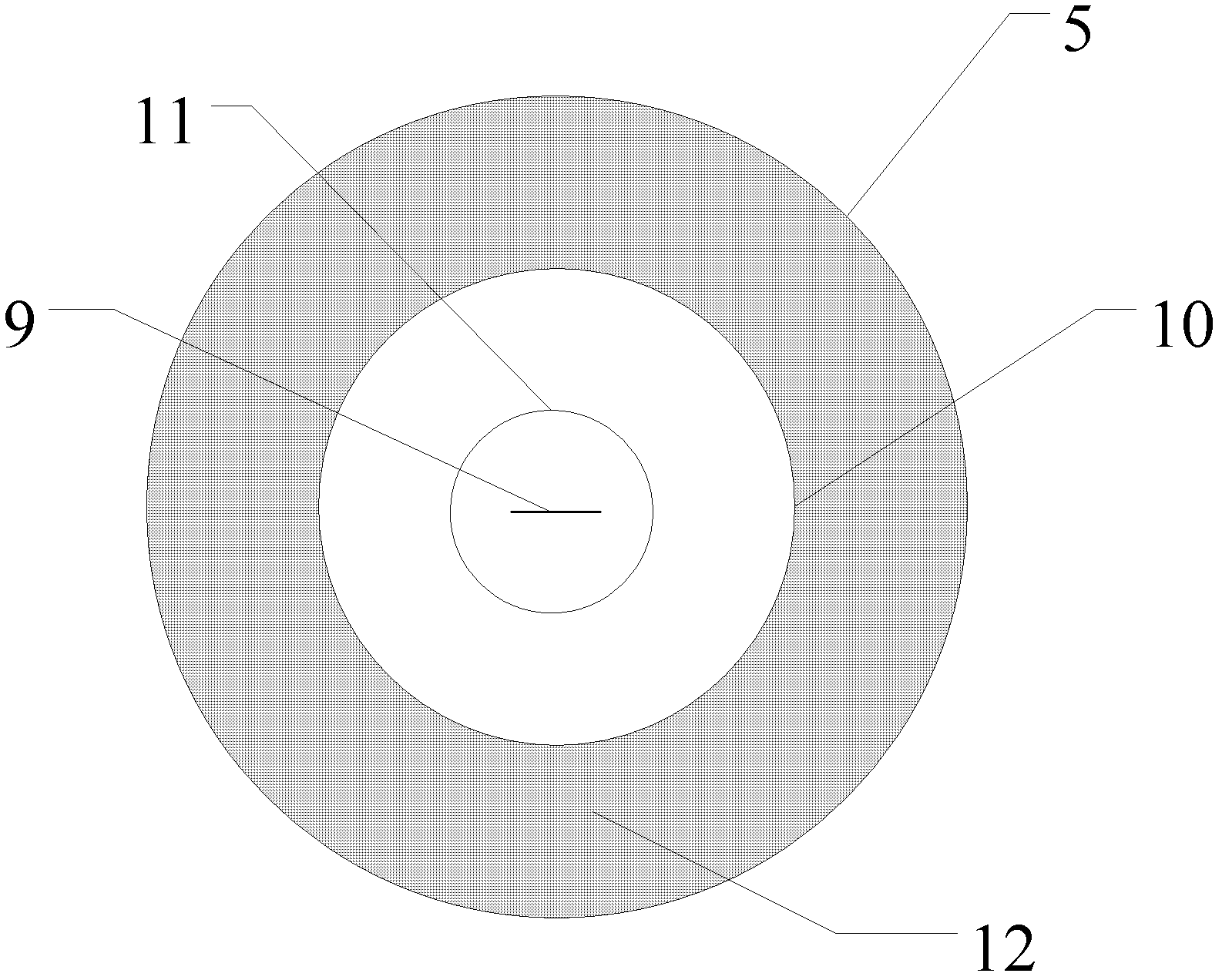

[0052] The crystallization tank used: no thickener is connected, the tank body is cylindrical and the top and bottom are hemispherical, the first sleeve and the second sleeve are cylinders with unsealed ends, the tank body, the first sleeve , The axis line of the second sleeve coincides, the agitator is on the axis line of the second sleeve, the structure diagram is shown in figure 1 and figure 2 ;

[0053] Preheat the monosodium glutamate feed solution to be crystallized after decolorization to about 70°C through a plate heat exchanger, enter the crystallization tank of the present invention from the first feed port, and evaporate under vacuum and a stirring speed of 80r / min Crystallization, the obtained crystals are precipitated to the bottom of the crystallization tank and sent out from the first crystal outlet,...

Embodiment 2

[0058] Embodiment 2: Utilize crystallization pot evaporation crystallization monosodium glutamate of the present invention

[0059] 1. Crystallization process

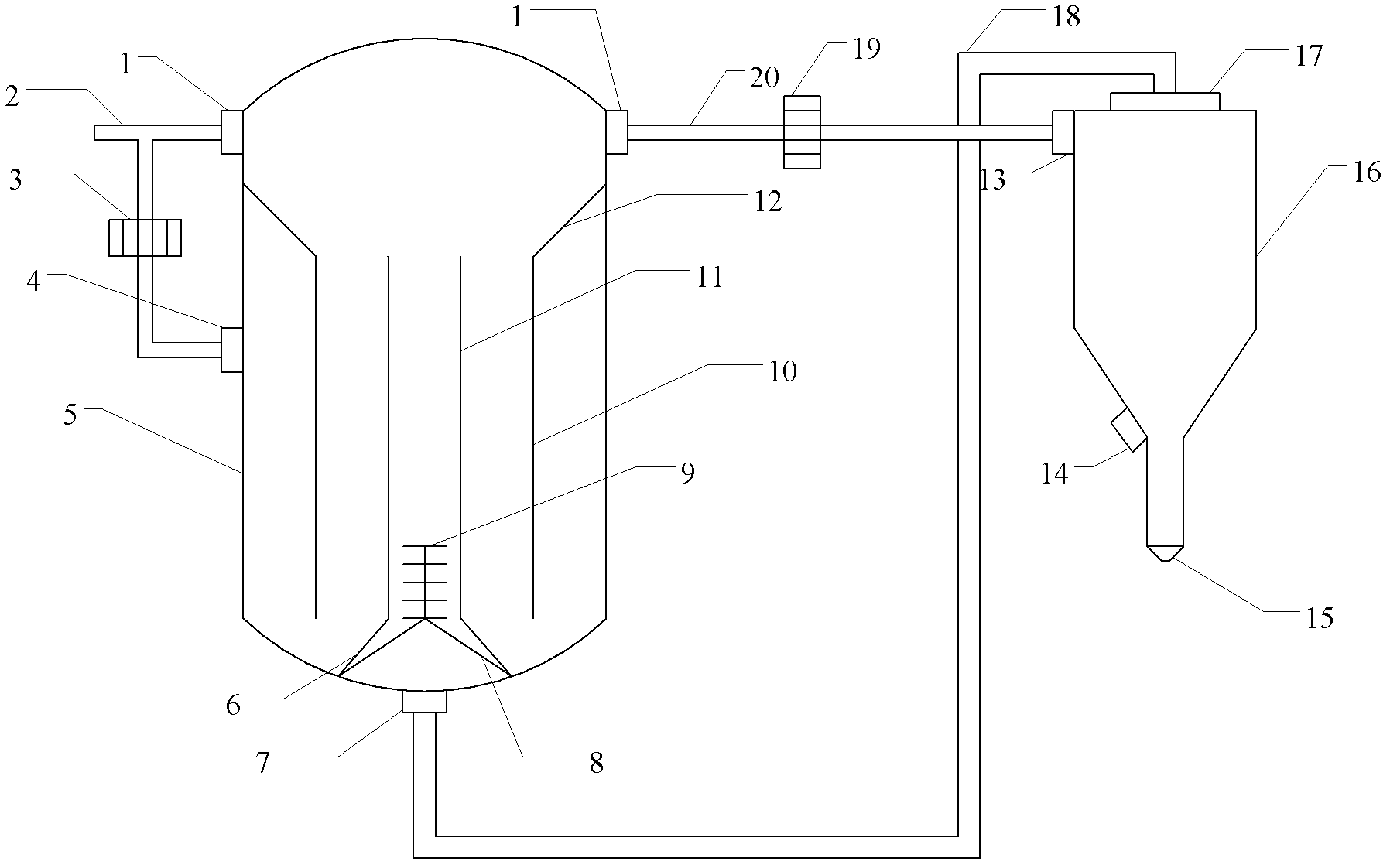

[0060] The crystallization tank used: connected with a thickener, the tank body is cylindrical and the top and bottom are hemispherical, the first sleeve and the second sleeve are cylinders with unsealed ends, the tank body, the first sleeve, The axes of the second sleeve coincide with each other, and the agitator is on the axis of the second sleeve; the thickener is a cylindrical funnel-shaped container, and the structure diagram is shown in figure 2 and image 3 .

[0061] The monosodium glutamate feed solution to be crystallized after decolorization is preheated to about 70°C through a plate heat exchanger, and enters the crystallization tank of the present invention from the first feed port, and evaporates under vacuum and a stirring speed of 90r / min Crystallization, the obtained crystals are precipitated to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com