Wet detoxification method of hexavalent chromium contained alkali waste residues

A technology of wet detoxification and hexavalent chromium, applied in the direction of improving process efficiency, etc., can solve the problems of incomplete detoxification and high treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

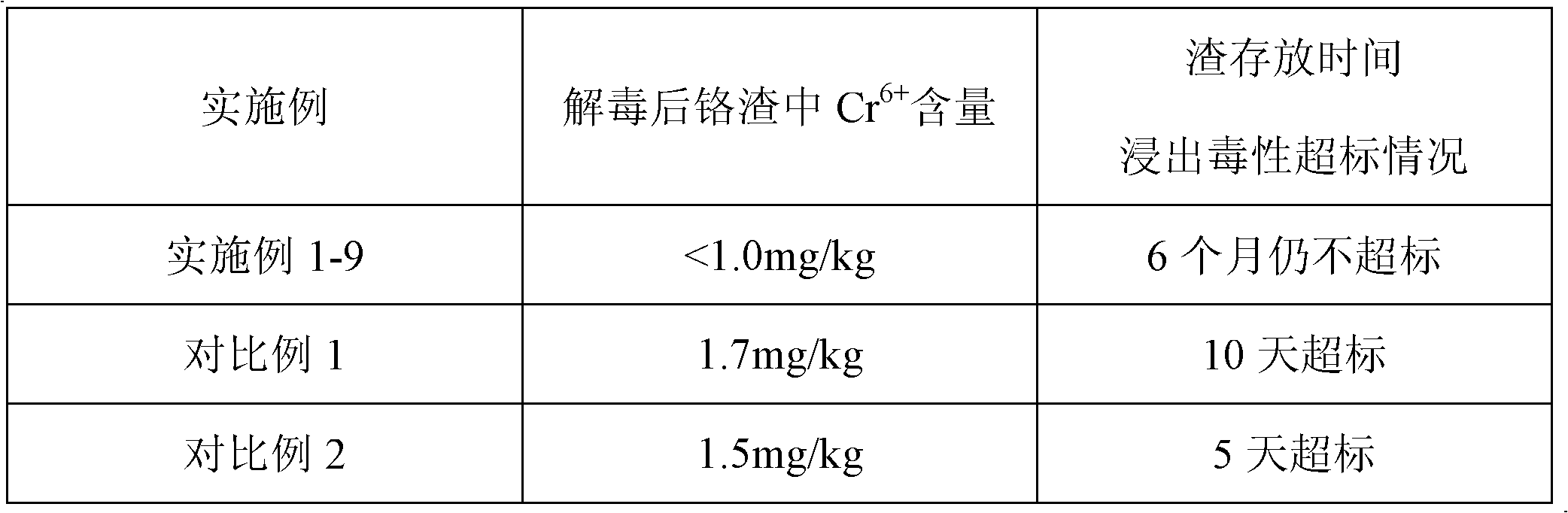

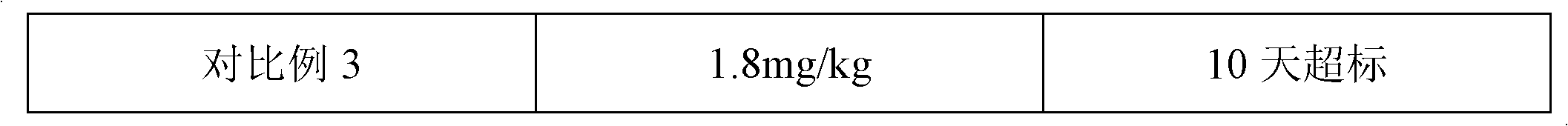

Examples

Embodiment 1

[0067] Slurry the chromium-containing iron slag containing 0.125% of hexavalent chromium completely in the pulping tank, add a certain amount of sulfuric acid to adjust the pH to 8.65, and then add 20% of the theoretical amount of calcium lignosulfonate, and wait until the calcium lignosulfonate After completely dispersed, add ferrous ammonium sulfate 4 / 3 times the theoretical amount to reduce hexavalent chromium, the reduction time is 1h, the temperature is 75°C, the liquid-solid ratio is 5:1, and the chromium slag after complete reduction can be filtered Obtain qualified iron slag whose leaching toxicity meets the national environmental protection industry standard promulgated by the Ministry of Environmental Protection, and the leaching toxicity does not exceed the standard after being piled in the open air for 6 months.

Embodiment 2

[0069] Completely slurry the chromium slag containing 0.137% hexavalent chromium in the slurry tank, add a certain amount of CO 2 Adjust the pH to 9.43, and then add 50% of the theoretical amount of calcium lignosulfonate. After the calcium lignosulfonate is completely dispersed, add ferrous sulfate 5 / 3 times the theoretical amount to reduce hexavalent chromium. The reduction time is 2 hours. The temperature is 80°C, the liquid-solid ratio is 4:1, and the chromium slag after complete reduction can be filtered to obtain qualified chromium slag whose leaching toxicity meets the national environmental protection industry standard promulgated by the Ministry of Environmental Protection. The leaching toxicity does not exceed the standard after being stacked in the open air for 6 months. .

Embodiment 3

[0071] Slurry the chromium-containing iron slag containing 0.176% hexavalent chromium in the slurrying tank, the slurrying time is 1h, the slurrying temperature is 80°C, and the liquid-solid ratio is 5:1. After the slurrying is complete, filter and the filtrate Return to the system, add the reduced mother liquor and filter residue into the slurrying tank with a liquid-solid ratio of 4:1, re-slurry, and raise the temperature to keep the temperature at 80°C. After the slurry is complete, add a certain amount of CO 2 Adjust the pH to 9.13, and then add 40% of the theoretical amount of sodium lignosulfonate. After the sodium lignosulfonate is completely dispersed, add ferrous sulfate 5 / 3 times the theoretical amount to reduce hexavalent chromium. The reduction time is 2 hours. The fully reduced chromium slag can be filtered to obtain qualified chromium slag whose leaching toxicity meets the national environmental protection industry standard promulgated by the Ministry of Environme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com