Power failure automatic knife retracting control method and device of numerical control machine tool

A technology of CNC machine tools and control methods, applied in the direction of digital control, electrical program control, etc., can solve the problem of high cost of machine tools and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

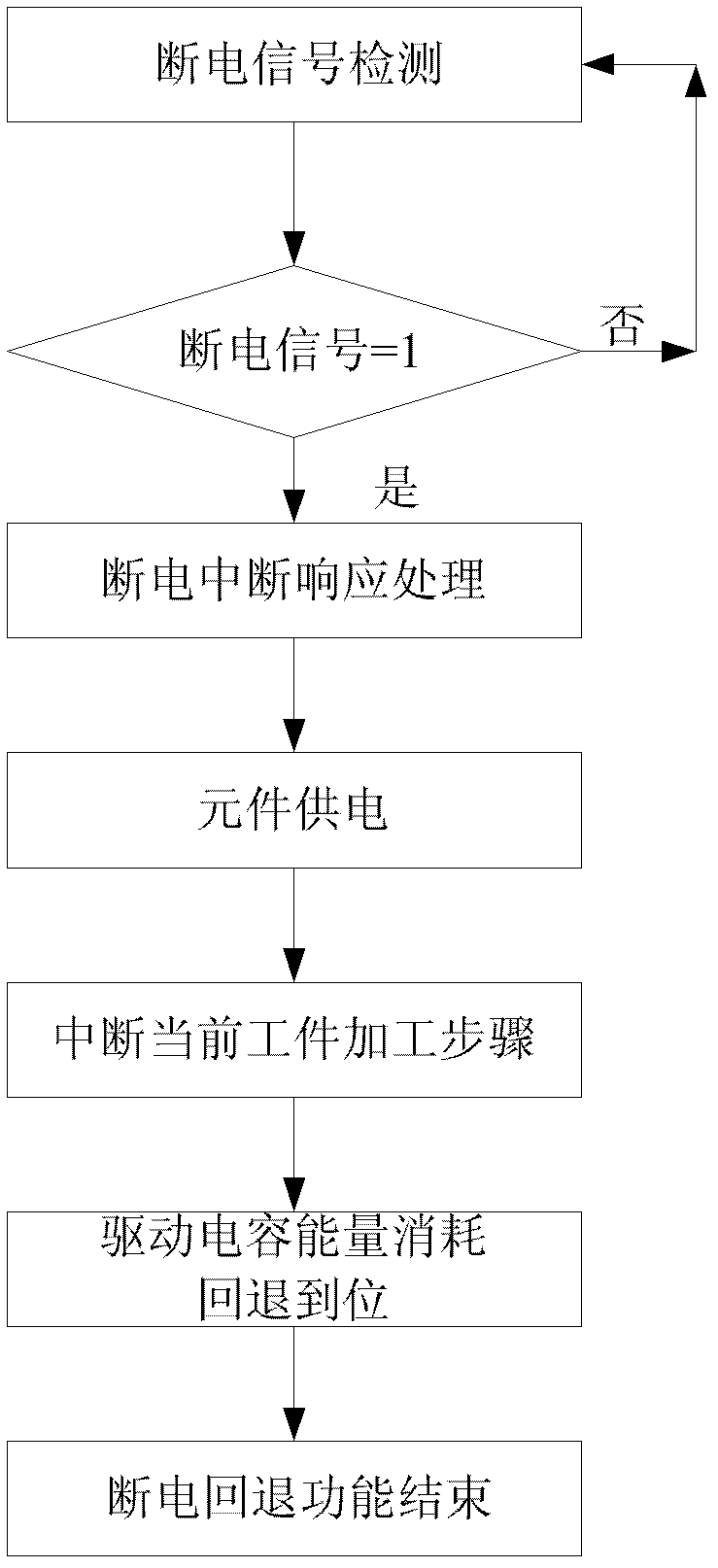

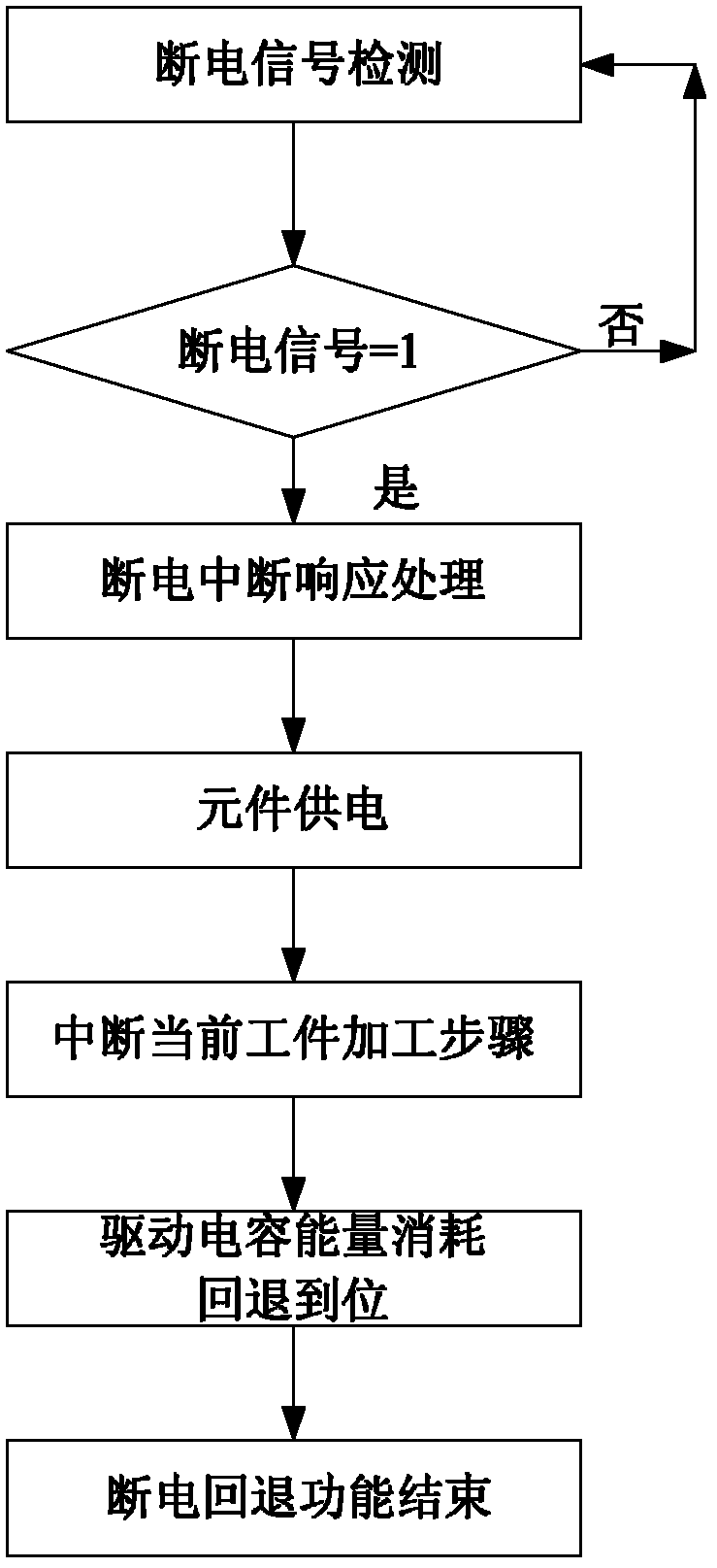

[0016] Embodiment 1: as figure 1 , figure 2 As shown, a control method for automatic tool retraction of a CNC machine tool after power failure includes the following steps:

[0017] 1) The power-off detection signal module detects the power-off signal, and when the power-off signal is detected, the power-off interruption response signal is processed by the programmable logic controller, and an interruption signal is sent;

[0018] 2) Start the charging power supply system to supply power, and the CNC machine tool control unit controls the machine tool to interrupt the processing program of the current workpiece; the charging power supply system supplies power to the programmable logic controller, the CNC machine tool control unit, and the servo drive module;

[0019] 3) Start the grinding wheel frame retraction module in the servo drive module, and the feed servo motor consumes energy for the feed servo motor capacitor module through the grinding wheel frame retraction modul...

Embodiment 2

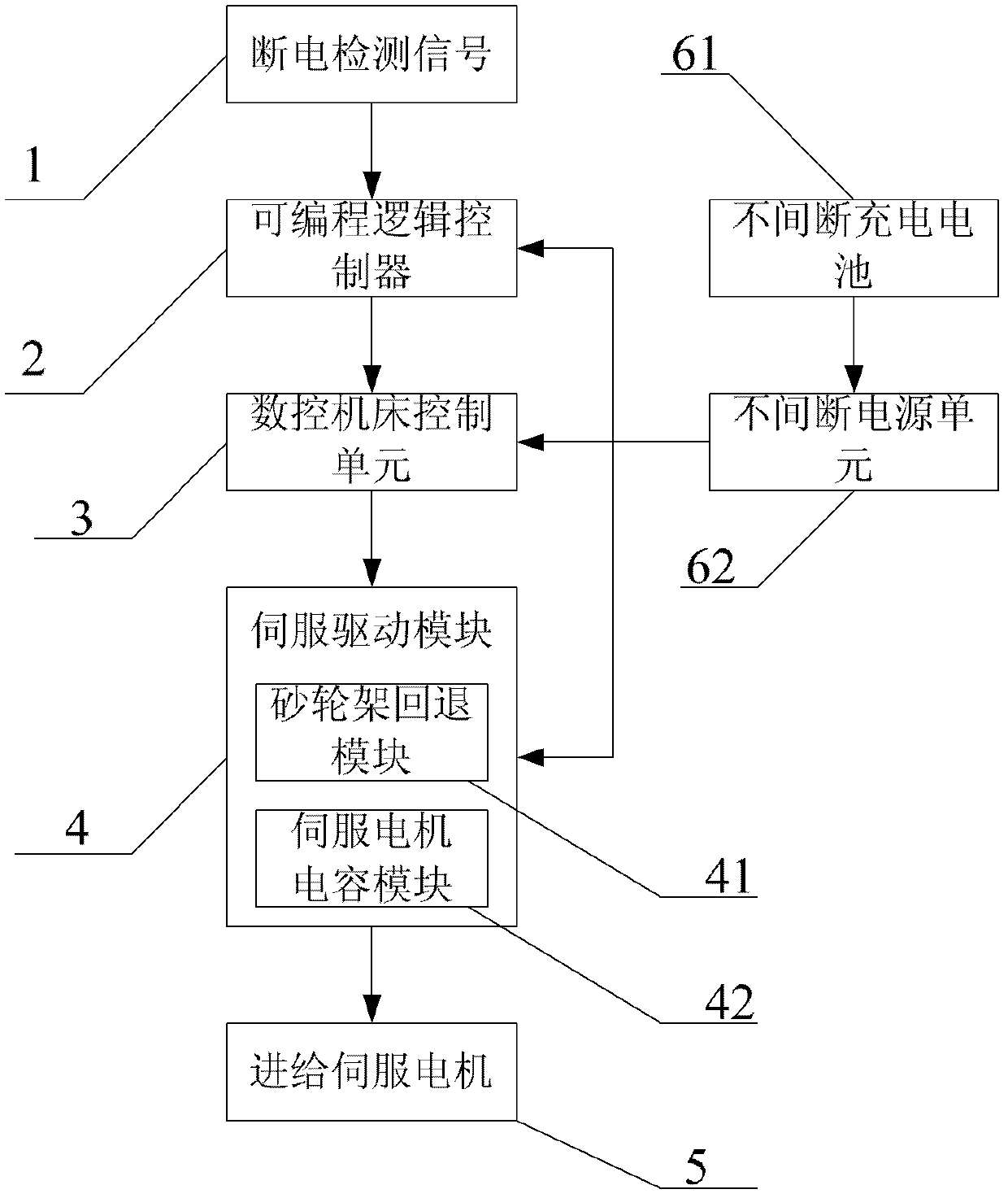

[0021] Embodiment 2: as figure 1 , figure 2 As shown, the present invention also provides a control device for automatic tool retraction of a CNC machine tool, including a power-off detection signal module 1 for detecting a power-off signal, and the power-off detection signal module 1 is driven to respond to a power-off interruption signal The programmable logic controller 2 for processing, the programmable logic controller 2 drives the CNC machine tool control unit 3 for controlling the machine tool to interrupt the processing of the current workpiece, the CNC machine tool control unit 3 drives the servo drive module 4, and the servo drive module 4 drives the Give the servomotor 5 retraction, and the described servo drive module 4 includes the grinding wheel carrier retraction module 41 and the servomotor capacitor module 42 for energy consumption of the feed servomotor capacitor module; the programmable logic controller 2 1. The CNC machine tool control unit 3 and the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com