Novel heating fiber material with bidirectional temperature regulating function and preparation method thereof

A heating fiber and function technology, applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of insufficient heat supply, insufficient heat preservation ability, low efficiency, etc., and achieve the effect of solving light and thin, efficient management, and saving raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Padding liquid formula:

[0038] Phase change microcapsules 2-30%

[0039] Binder 2-30%

[0040] Water 40-96%

[0041] Wherein, phase change microcapsules (preparation method refers to article Journal of Applied Polymer Science, 2005,97:390) main component is capsule core is phase change alkane, and shell layer is urea-formaldehyde resin, or polymers such as polyurethane, and particle size can be varied. Controlled between 100 nanometers and 1000 microns.

[0042] The adhesive is normal temperature adhesive NJ101 (provided by Jiangshan Hongxin Printing Material Co., Ltd.).

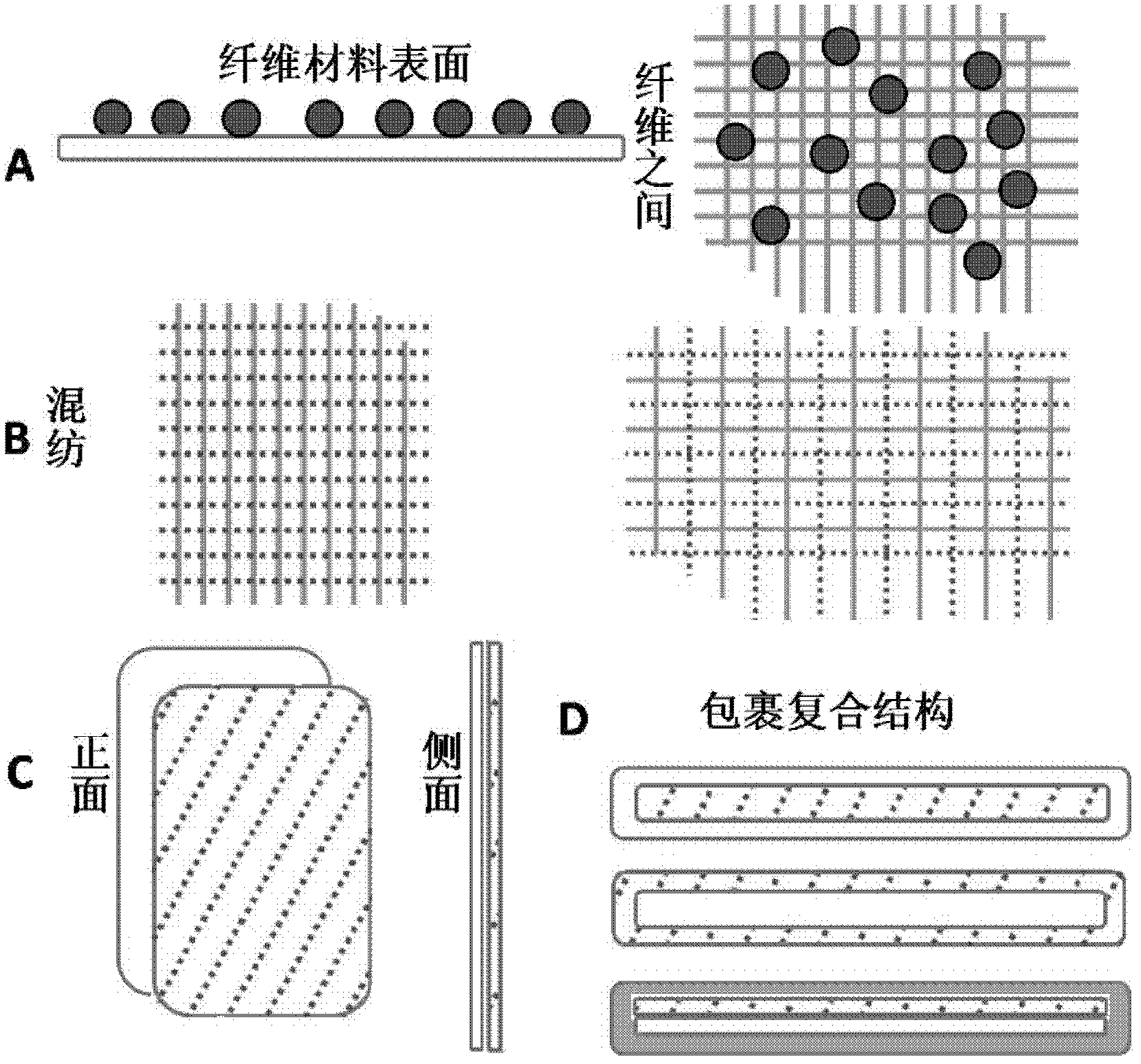

[0043] The heat-generating fiber (cupro ammonia fiber or cross-linked acrylate fiber is selected here) is dipped and rolled twice, and then dried at 80°C. A heating fiber material with two-way temperature regulation function according to the present invention can be obtained.

Embodiment 2

[0045] 200g of phase-change microcapsule material dispersion (for the preparation method refer to the article Journal of Applied Polymer Science, 2005, 97: 390; Colloidal and Polymer Science, 280: 290), with 800g of distilled water, 1.5g of sodium polypropylene and 2g of di-succinate The alkyl ester sulfonate is mixed well until no solid material is evident. Use a commercially available pump spray bottle to spray the dispersion system obtained above evenly onto the heating fiber material. In this example, cupro ammonia fiber or cross-linked acrylate fiber can be used, and the spraying amount is the mass of the fiber material. 20%, and then dry the sprayed flakes at 100°C to obtain a heating fiber material with two-way temperature regulation function according to the present invention.

Embodiment 3

[0047] The phase change energy storage fiber, PVA / paraffin phase change energy storage fiber is selected here (refer to the Journal of Composite Materials for the preparation method, 2008, 25, 17-22), and the cross-linked acrylate fiber and acrylic fiber (the ratio of the three is phase change energy storage fiber / heating fiber / acrylic fiber, 80:4:16), for blending. After weaving, the heating fiber material with two-way temperature regulation function of the present invention can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com