Improved microporous polymer film and preparation method thereof

A microporous polymer, an improved technology, applied in the field of applied chemical industry, can solve the problems of unreported thermal stability of β crystal, unreported thermal stability, difficult metal drum peeling, etc., to achieve good film forming stability and Pore-forming performance, improved porosity, and excellent productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

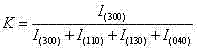

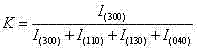

[0031] According to the extrusion method, the molten polymer mixture (the specific composition is described in detail below) at 210 o After extrusion at the extrusion temperature of C, at a melt stretching rate of 50 m / min, the stretching is carried out by a pull-out roller to 50 times respectively, and solidified to obtain a polypropylene base film. at 120 o C crystallization, the crystallization time is 0.1min, and the recorded polypropylene base film β crystal content K is 0.89, and on the DSC melting curve of the obtained polypropylene base film, the melting initiation temperature of the β crystal melting peak (T onset ) for 147 o C, the termination melting temperature (T endset ) for 156 o c. Next the two polypropylene base films were stretch oriented in machine and transverse directions and finally set.

[0032] The polypropylene film has the following composition:

[0033] 84.95wt% high isotactic polypropylene homopolymer (PP), its 13 The C-NMR isotacticity...

Embodiment 2

[0046] According to the extrusion method, the molten polymer mixture (the specific composition is described in detail below) at 210 o After extrusion at the extrusion temperature of C, at a melt stretching rate of 2m / min, the stretching is drawn to 2 times through the take-off roller, and solidified to obtain a polypropylene base film. at 120 o C crystallization, crystallization time 3min. The beta crystal content K of the polypropylene base film was measured to be 0.94. On the DSC melting curve of the prepared polypropylene-based film, the melting onset temperature of the β crystal melting peak (T onset ) for 147 o C, the termination melting temperature (T endset ) for 158 o c. Next, the polypropylene base film was stretch-oriented in the longitudinal and transverse directions, and finally set.

[0047] The polypropylene film has the following composition:

[0048] 84.95wt% high isotactic polypropylene homopolymer (PP), its 13 The C-NMR isotacticity is 98% and ...

Embodiment 3

[0061] According to the extrusion method, the molten polymer mixture (the specific composition is described in detail below) at 210 o After extrusion at the extrusion temperature of C, at a melt stretching rate of 2m / min, the stretching is drawn to 2 times through the take-off roller, and solidified to obtain a polypropylene base film. at 130 o C crystallization, crystallization time 5min. The beta crystal content K of the polypropylene base film was measured to be 0.91. On the DSC melting curve of the prepared polypropylene-based film, the melting onset temperature of the β crystal melting peak (T onset ) for 145 o C, the termination melting temperature (T endset ) for 156 o c. Next, the polypropylene base film was stretch-oriented in the longitudinal and transverse directions, and finally set.

[0062] The polypropylene film has the following composition:

[0063] 84.95wt% high isotactic polypropylene homopolymer (PP), its 13 The C-NMR isotacticity is 98% and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com