Preparation method of acrylic resin/graphene oxide nanometer composite leather finishing agent

A leather finishing agent, acrylic resin technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of poor film-forming mechanical properties, hot stickiness and cold brittleness, external temperature sensitivity, etc., and achieves smooth hand feel and improved tear strength. , the effect of flame retardant and antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

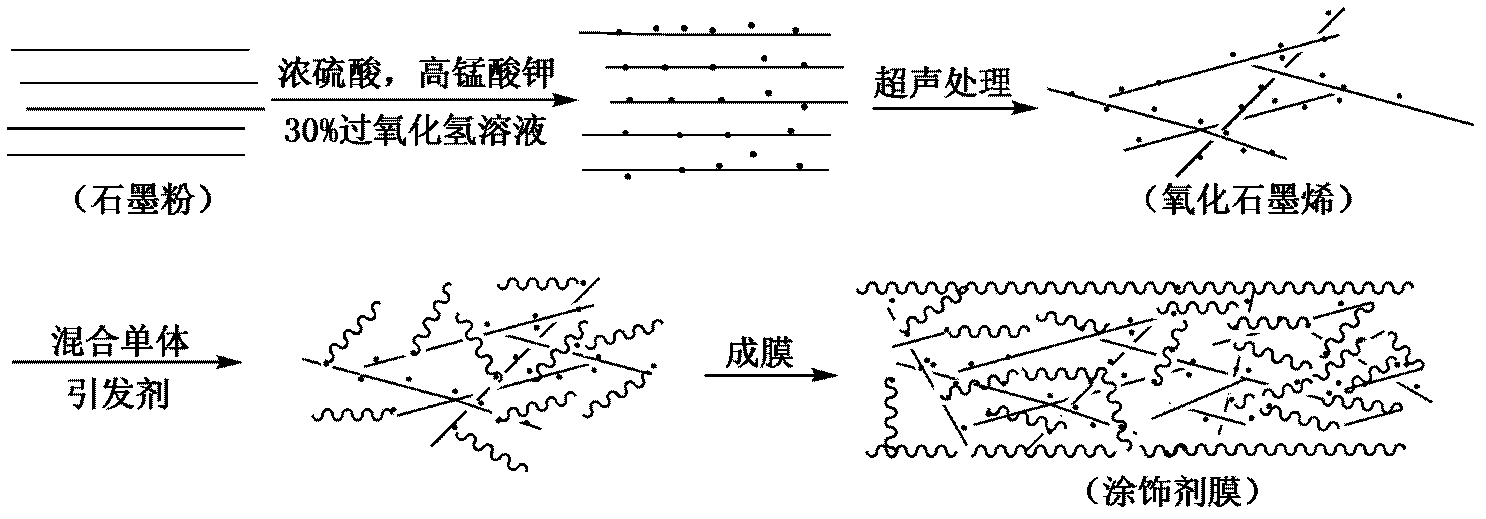

[0020] Example 1: see figure 1 ,

[0021] 1) Preparation of graphene oxide suspension

[0022] Stir and mix 6 parts of graphite powder with a particle size of <30 microns, 3 parts of sodium nitrate and 60 parts of concentrated sulfuric acid with a mass fraction of 98% in parts by mass at less than 35°C and slowly add 14 parts of potassium permanganate to react for 24 Slowly add 300 parts of deionized water after 1 hour, heat up to 58°C and continue to react for 1.5 hours, then add 16 parts of hydrogen peroxide solution with a mass fraction of 30% dropwise, precipitate and wash repeatedly for several times, then use sodium hydroxide to adjust the pH to 6. Finally, centrifuge and add the separated precipitate graphene oxide into 100 parts of deionized water, and perform ultrasonic treatment for 30 minutes to obtain graphene oxide nano-suspension;

[0023] 2) Graphene oxide / monomer mixture:

[0024] Get 8 parts of graphene oxide suspensions and 10 parts of methyl acrylate, 3 p...

Embodiment 2

[0029] 1) Preparation of graphene oxide suspension

[0030] Stir and mix 6 parts of graphite powder with a particle size of <30 microns, 3 parts of sodium nitrate and 60 parts of concentrated sulfuric acid with a mass fraction of 98% in parts by mass at less than 35°C and slowly add 14 parts of potassium permanganate to react for 24 Slowly add 300 parts of deionized water after 1 hour, heat up to 58°C and continue to react for 1.5 hours, then add 16 parts of hydrogen peroxide solution with a mass fraction of 30% dropwise, precipitate and wash repeatedly for several times, then use sodium hydroxide to adjust the pH to 6. Finally, centrifuge and add the separated precipitate graphene oxide into 100 parts of deionized water, and perform ultrasonic treatment for 30 minutes to obtain graphene oxide nano-suspension;

[0031] 2) Graphene oxide / monomer mixture:

[0032] Get 9 parts of graphene oxide suspensions and 6 parts of methyl acrylate, 4 parts of ethyl acrylate, 26 parts of bu...

Embodiment 3

[0037] 1) Preparation of graphene oxide suspension

[0038] Stir and mix 6 parts of graphite powder with a particle size of <30 microns, 3 parts of sodium nitrate and 60 parts of concentrated sulfuric acid with a mass fraction of 98% in parts by mass at less than 35°C and slowly add 14 parts of potassium permanganate to react for 24 Slowly add 300 parts of deionized water after 1 hour, heat up to 58°C and continue to react for 1.5 hours, then add 16 parts of hydrogen peroxide solution with a mass fraction of 30% dropwise, precipitate and wash repeatedly several times, then use sodium hydroxide to adjust the pH to 6. Finally, centrifuge and add the separated precipitate graphene oxide into 100 parts of deionized water, and perform ultrasonic treatment for 30 minutes to obtain graphene oxide nano-suspension;

[0039] 2) Graphene oxide / monomer mixture:

[0040] Get 10 parts of graphene oxide suspension and 8 parts of methyl acrylate, 5 parts of ethyl acrylate, 28 parts of butyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com