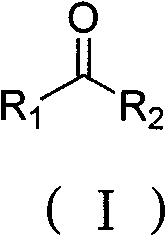

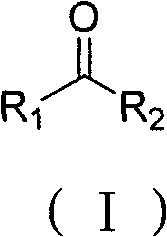

Method for preparing corresponding alcohol through carbonyl compound selective hydrogenation

A carbonyl compound and selectivity technology, applied in the field of selective hydrogenation of carbonyl compounds to prepare corresponding alcohols, can solve problems such as poor selectivity, and achieve the effects of low cost, good selectivity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the autoclave, add 600 milliliters of water, 100 grams of acetophenone and 20 grams of catalyst, and adjust the pH value of the solution to 9.0 with potassium hydroxide, wherein the content of Raney Ni in the catalyst used is 90.0 mass %, Ni(OH) 2 The content is 4.0% by mass, Ca(OH) 2 The content is 4.0% by mass, Al 2 o 3 The content is 2.0% by mass, seal the autoclave, fill the autoclave with nitrogen to 3.0MPa to replace the air in the kettle, then fill the hydrogen to 3.0MPa to replace the nitrogen in the kettle, fix the initial pressure of hydrogen to 3.0MPa, and the speed is 840 rpm, the reaction temperature is controlled At about 50°C, the rotation speed is 840 rpm, until the hydrogen pressure no longer changes, the reaction ends. The catalyst was filtered off, and the filtrate was extracted with ethyl acetate, concentrated, and weighed 99.4 g. The yield of 1-phenylethanol was 97%, and the selectivity was 99.2%.

[0023] The product is detected by gas chroma...

Embodiment 2

[0027] Add 500 milliliters of ethanol in autoclave, 100 grams of 4-phenyl-3-buten-2-ketone and 20 grams of catalyzer, the pH of solution with potassium carbonate regulator is 9.5, wherein the content of Raney Ni in the catalyzer used is 95.0% by mass, Ni(OH) 2 The content is 1.5% by mass, Ca(OH) 2 The content is 1.5% by mass, Al 2 o 3 content of 2.0% by mass, seal the autoclave, fill the autoclave with nitrogen to 3.0MPa to replace the air in the kettle, then fill the hydrogen to 3.0MPa to replace the nitrogen in the kettle, fix the initial pressure of hydrogen to 2.5MPa, control the reaction temperature at about 45°C, and the rotation speed is 760 rpm, until the hydrogen pressure no longer changes, the reaction is over. The catalyst was filtered off, the filtrate was concentrated and weighed 99.5 g, the yield of 4-phenyl-3-buten-2-ol reached 97.9%, and the selectivity was 99.7%. The product is detected by gas chromatography, and the gas phase conditions are column tempera...

Embodiment 3

[0031] Add 500 milliliters of water, 100 grams of acetone and 20 grams of catalyst in the autoclave, and adjust the pH of the solution with sodium carbonate to be 8.5, wherein the content of Raney Ni in the catalyst used is 92.0 mass %, Ni(OH) 2 The content is 3.5% by mass, Ca(OH) 2 The content is 3.5% by mass, Al 2 o 3 The content of hydrogen is 1.0% by mass, seal the autoclave, fill the autoclave with nitrogen to 3.0MPa to replace the air in the kettle, then fill the hydrogen to 3.0MPa to replace the nitrogen in the kettle, fix the initial pressure of hydrogen to 2.5MPa, control the reaction temperature at about 55°C, and the rotation speed is 620 rpm, until the hydrogen pressure no longer changes, the reaction is over. The catalyst was filtered off, and the filtrate was extracted with ethyl acetate, concentrated, and weighed 100.9 g. The yield of isopropanol reached 97.3%, and the selectivity was 99.7%. The product is detected by gas chromatography, and the gas phase con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com