Design method of one-step molded gas bag, and one-step molded safe gas bag

A design method and technology for airbags, which are applied to vehicle safety arrangements, pedestrian/occupant safety arrangements, fabrics, etc., can solve problems such as inability to carry out industrialized production, large investment in production equipment and raw materials, and cumbersome and complicated weaving and processing processes. The effect of gas barrier properties, improved breaking strength and good damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0026] Concrete embodiment: following examples all carry out under following raw material and weaving process condition:

[0027] Raw materials: Select high-strength nylon industrial filaments with warp and weft yarn numbers of 470Dtex, single strength of 7-9CN / Dtex, and elongation at break of 18-24%;

[0028] Weaving process: Jacquard air-jet loom is used for weaving. The warp density on the upper machine is 44 threads / cm, the weft density is 38 threads / cm, and the tension on the upper machine is 110CN / loom.

Embodiment 1

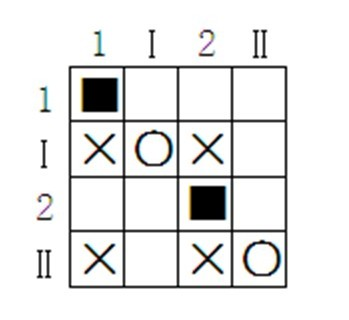

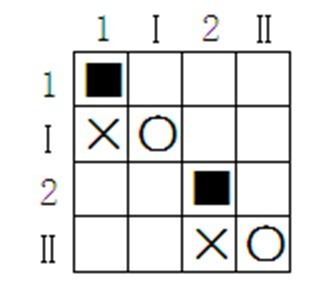

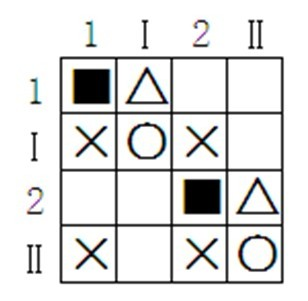

[0029] Embodiment 1: airbag bag body 1 adopts figure 1 The shown double layer plain weave, airbag double edge banding 2 adopts figure 2 , 3 For any one of the double-layer plain weave stitches, the width of the edge banding is 3 mm, and the edge banding of the airbag and the cutting line area 4 and the border area 5 between adjacent airbags are separately woven with a double-layer weave and a single-layer weave.

[0030] During the weaving process, when the edge banding of the airbag and the cutting line area 4 and the border area 5 between adjacent airbags are woven with double-layer weaving, its warp and weft density is basically consistent with that of the airbag body 1, and the warp openings in the entire width direction are clear, and the weaving The mouth is parallel, which is good for beating up and the surface of the cloth is smooth and smooth, and the appearance effect is good. When single-layer weaving is used, the latitude and longitude density of the edge bandin...

Embodiment 2

[0032] Embodiment 2: Airbag bag body 1 adopts figure 1 Double-layer plain weave, airbag edge banding and cutting line area 4 and the junction area 5 between the connected airbags adopt double-layer plain weave or other double-layer fabric weaves with joints, and airbag double edge banding 2 adopts figure 2 , 3 Any one of the two-layer plain weave joints is the surface warp sinking and inner weft jointing ( figure 2 ) or inside warp lifting and table weft connection ( image 3 ), and the edge widths are 3mm and 1mm respectively for weaving.

[0033]The airbag fabric obtained by designing the width of the above-mentioned airbag edge banding was tested for the relevant performance of the airbag edge banding, and the test results are shown in Table 1.

[0034] Table 1 Embodiment 2 adopts the comparative results of different edge banding widths

[0035]

[0036] It can be seen from the above table that when the airbag edge is used with a large edge width, when the fabric s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com