Cylinder head guide column drilling rectifying tool and application method

A cylinder head and column hole technology, which is applied in the field of cylinder head drilling guide column hole correction tools, can solve the problems of high size and position accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

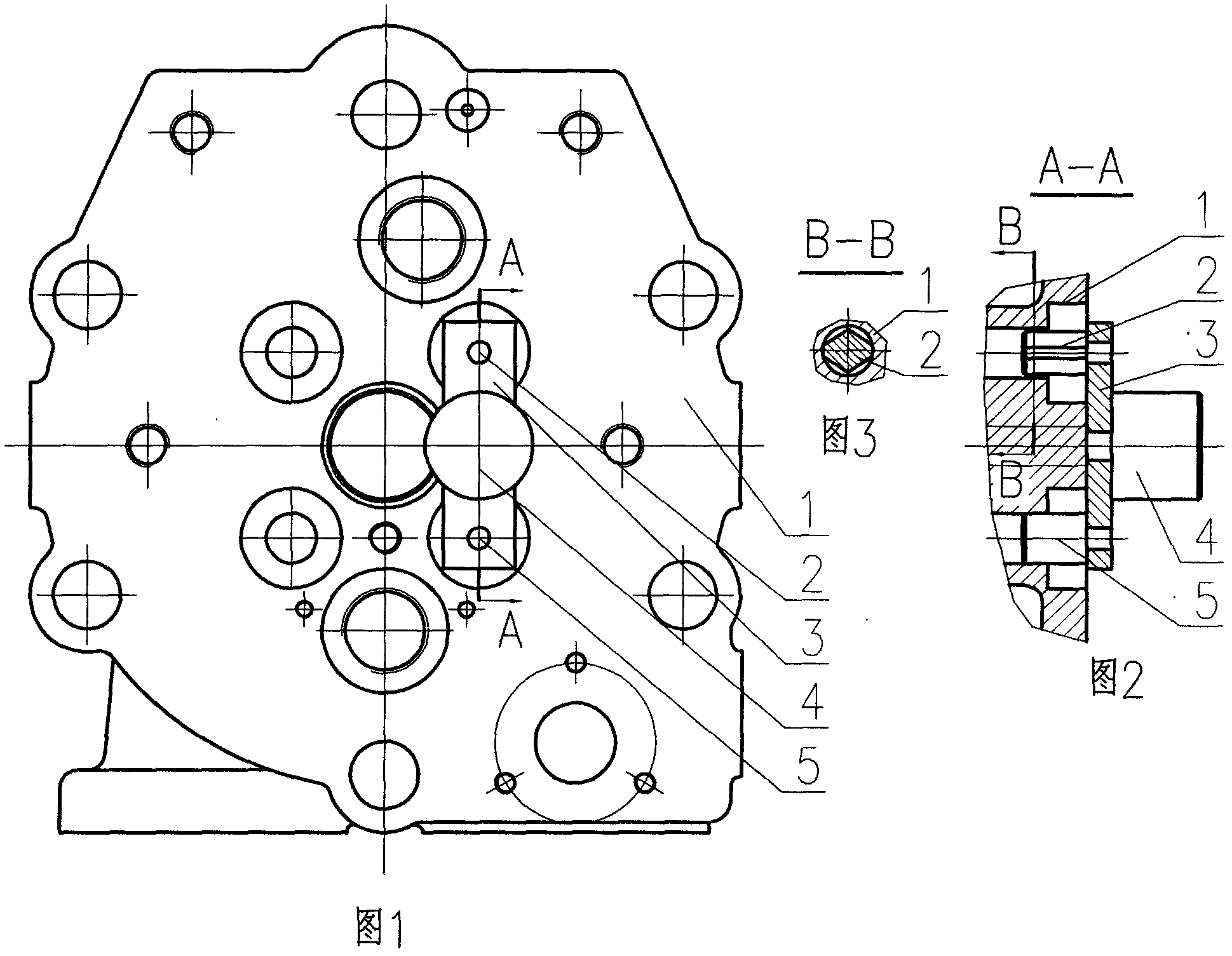

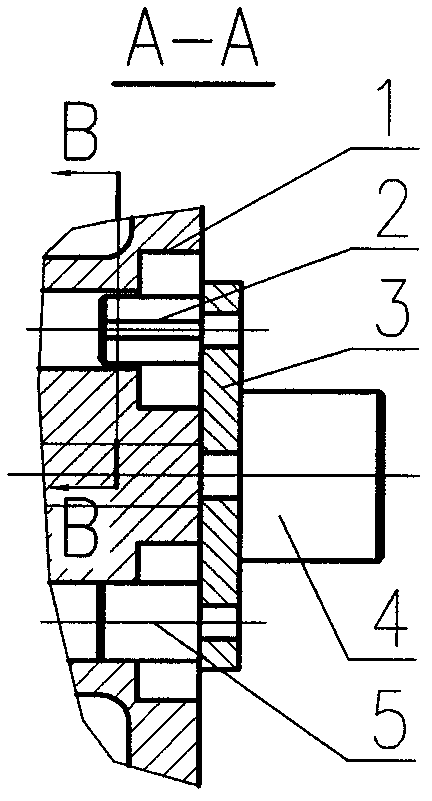

[0012] The accompanying drawing is an assembly drawing of the drill guide post hole correction tool for the cylinder head (1) of a 16V240ZJ diesel engine.

[0013] Referring to the accompanying drawings, the diameter of the conduit installation hole of the 16V240ZJ diesel engine cylinder head (1) is 28mm. The diameter of the guidepost hole is 22mm. The distance between the two conduit holes on the same side is 104±0.2mm. middle. The conduit mounting hole must be processed from the combustion face of the cylinder head (1) together with its coaxial valve seat hole, and the guide post hole will be processed from the other side of the cylinder head (1). According to the working principle of the cylinder head (1), the guide post holes on the same side are associated with the conduit mounting holes. The position of the guide post hole is determined by the position of the cylinder head (1) conduit mounting hole, and the positioning reference of the calibration tool is exactly the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com