Blade for carrying out groove processing and cutting

A grooving and blade technology, which is applied to lathe cutting tools, metal processing equipment, turning equipment, etc., can solve problems such as flying out of the tool body, wear or chipping, and difficulty in complete contact between the upper and lower positioning surfaces, etc., to achieve Improve the ability to withstand cutting force and impact resistance, low manufacturing precision requirements, and increase the effect of positioning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

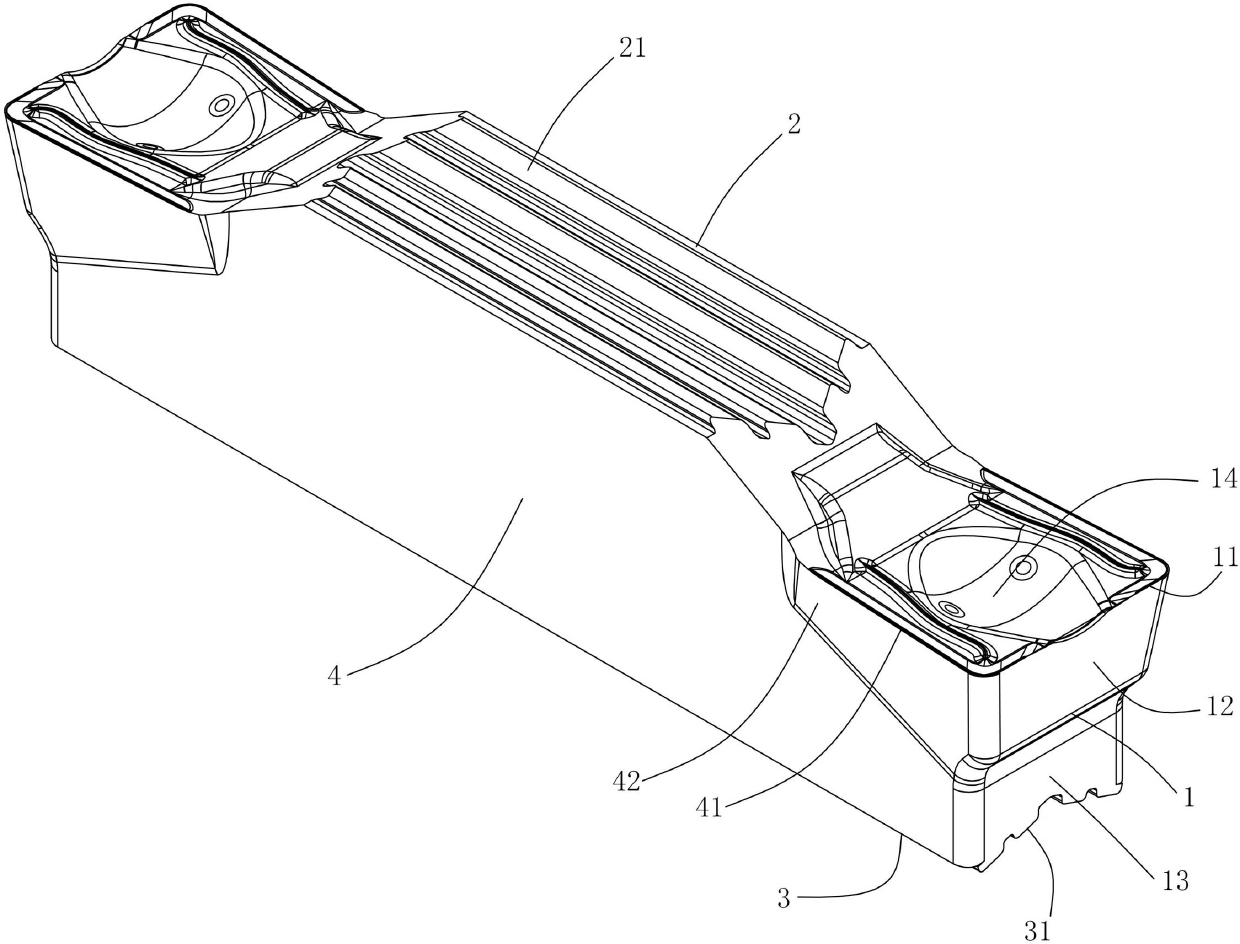

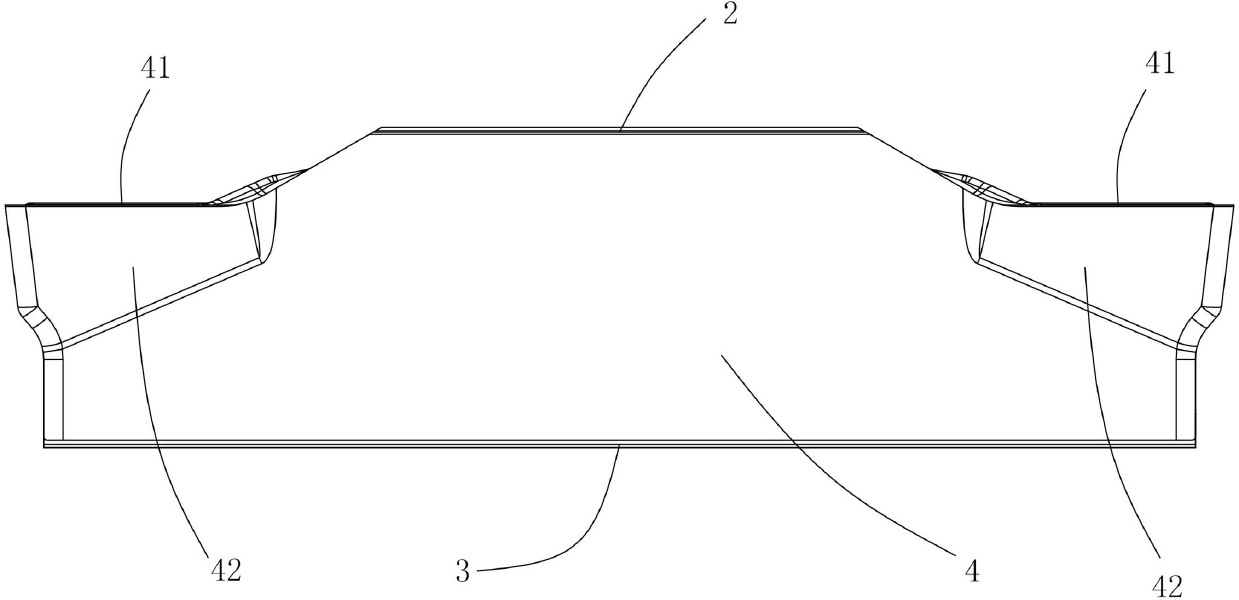

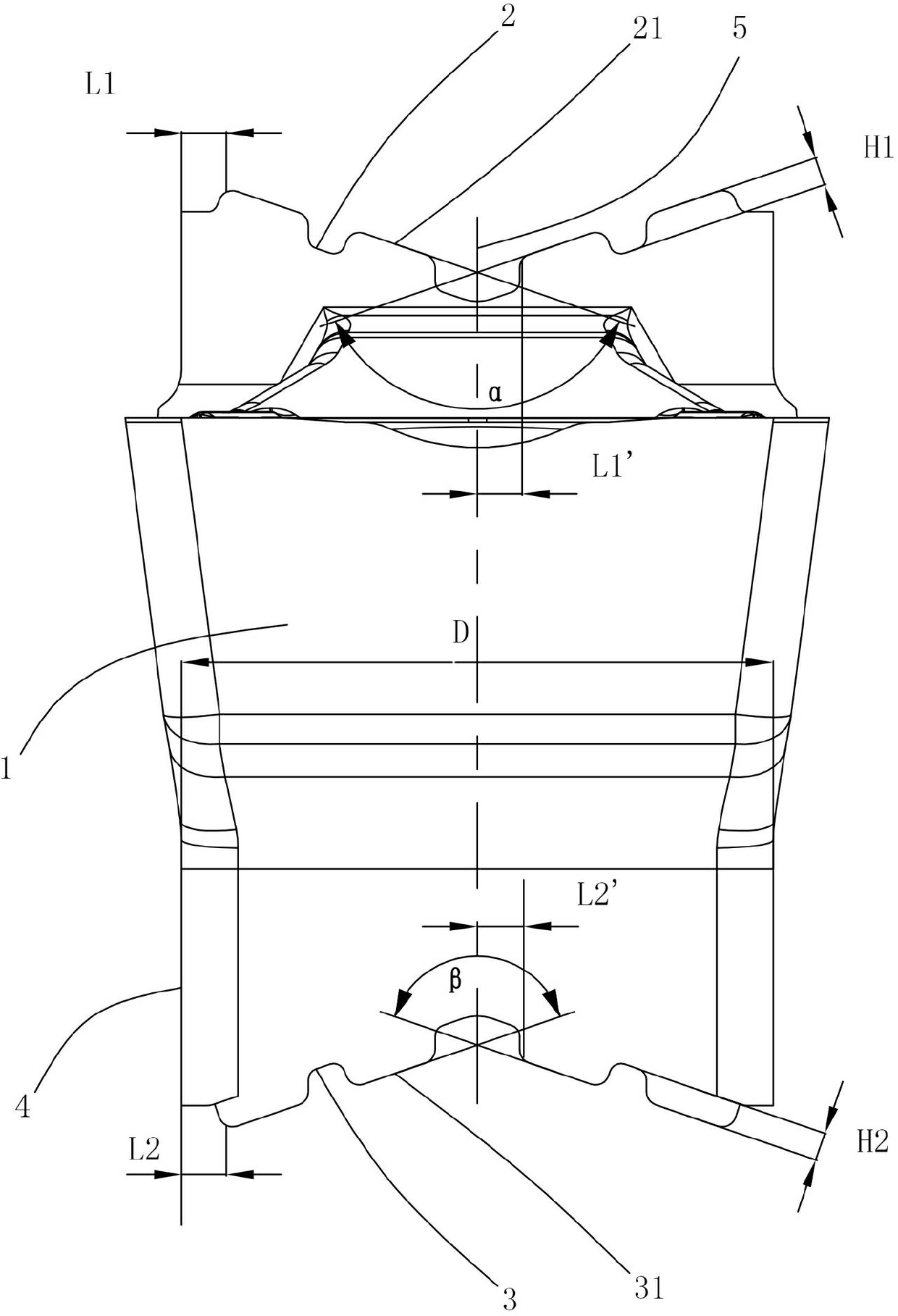

[0022] Figure 1 to Figure 4 It shows the first embodiment of the cutting insert for grooving of the present invention, which includes an upper positioning surface 2, a lower positioning surface 3, two side surfaces 4 and two end surfaces 1, and the two side surfaces 4 are connected to the upper positioning surface 2 and the lower positioning surface 3, the middle part of the upper positioning surface 2 and the lower positioning surface 3 is concave, and the cutting part of the insert is provided with a side edge 41, a side edge flank 42, an end edge 11, an end edge flank 12 and a chip guide groove 14 , the end face 1 is also provided with an end positioning surface 13, the structures at both ends of the blade are arranged symmetrically, the upper positioning surface 2 is provided with M discontinuous upper positioning platforms 21, and the lower positioning surface 3 is provided with N discontinuous lower positioning platforms. Positioning platform 31, 2≤M≤10, 2≤N≤10, M=N=4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com