Water-cooling temperature-control forming die for light alloy plates

A warm forming and light alloy technology, applied in the field of molds and molds in mechanical engineering, can solve the problems of reduced production efficiency, insufficient circulation cooling, lack of temperature acquisition and control equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

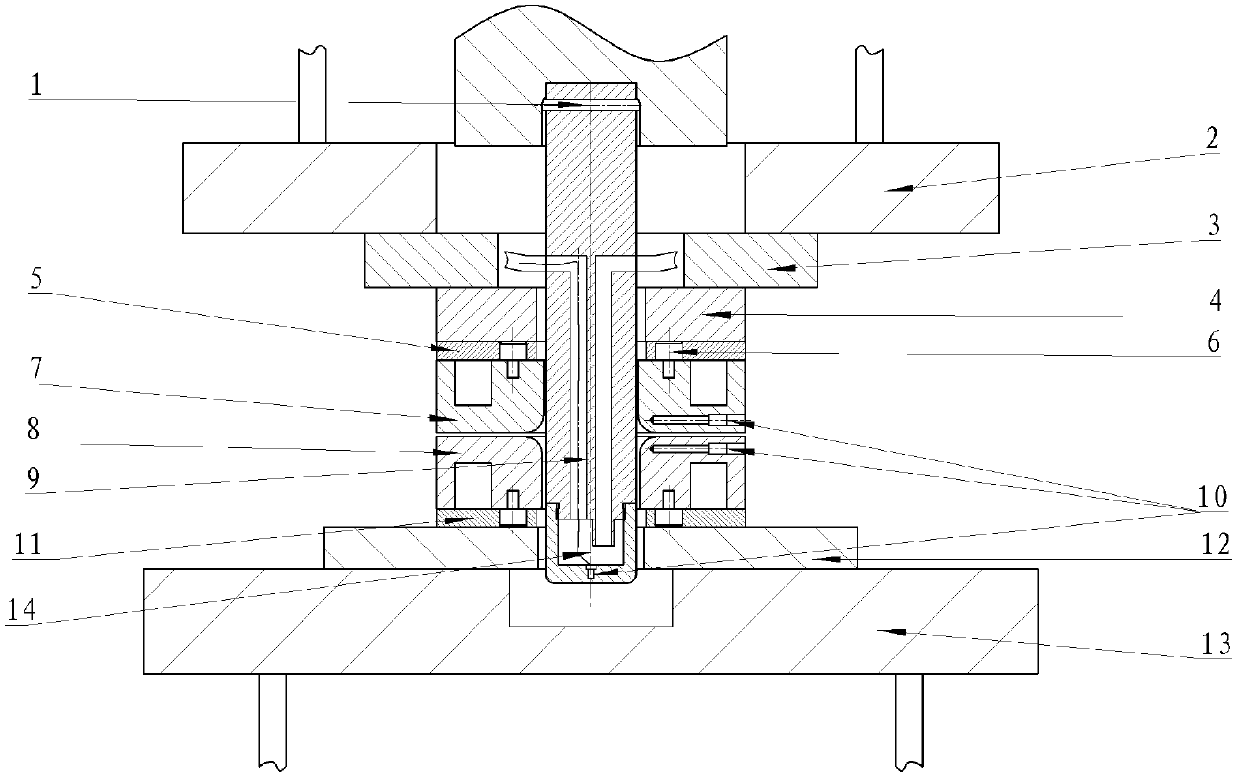

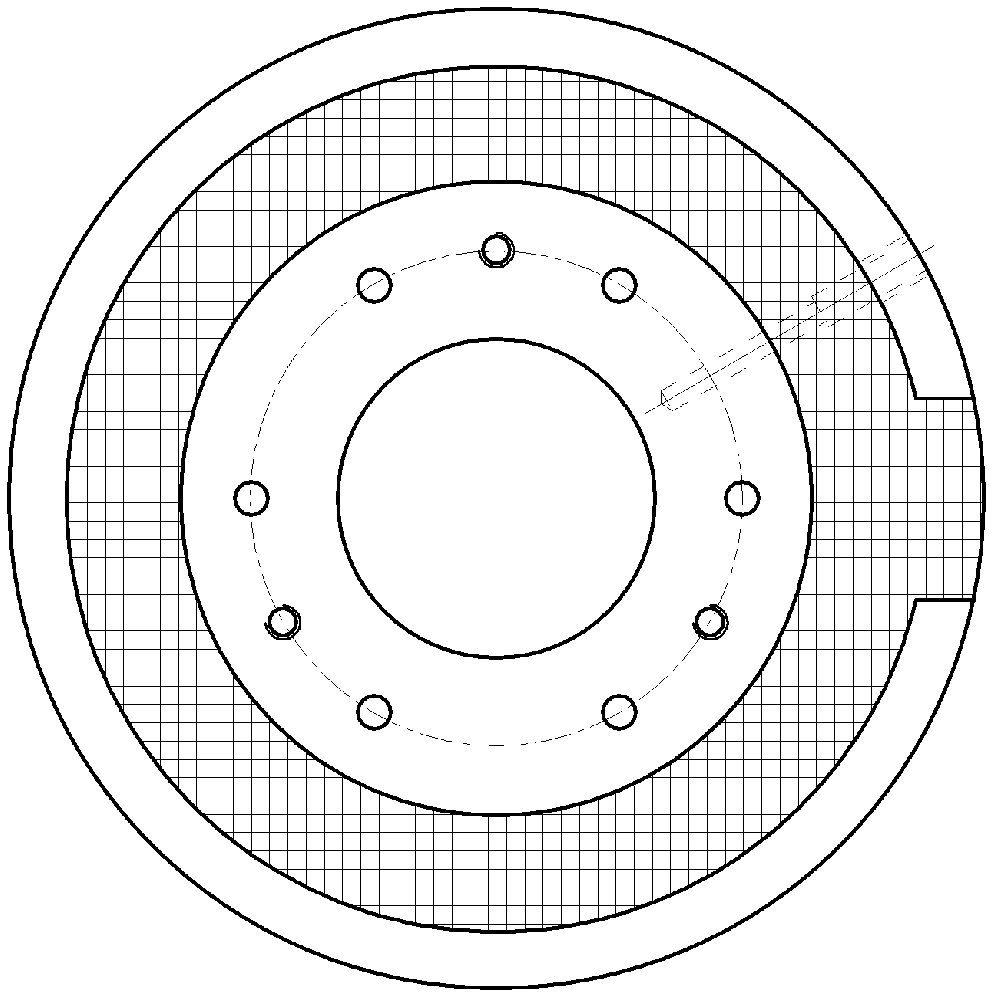

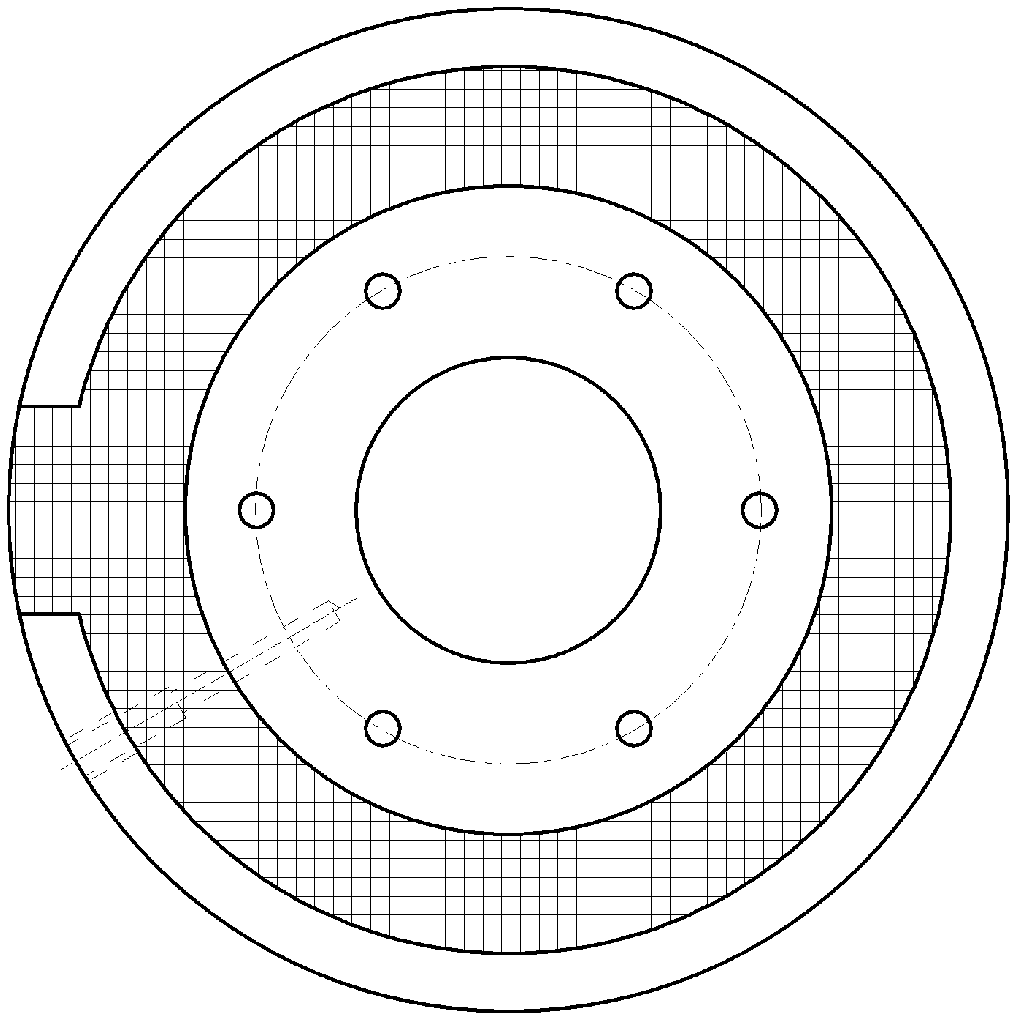

[0020] like figure 1 As shown, this embodiment provides a water-cooled and temperature-controlled forming mold for light alloy plates, which mainly consists of pins 1, upper template 2, first upper backing plate 3, second upper backing plate 4, upper asbestos gasket 5, feet 6, The blank holder ring 7, the die 8, the punch 9, the hot spot couple 10, the lower asbestos gasket 11, the lower backing plate 12, the lower template 13 and the circulating water cooling system 14 are composed. The punch 9 is assembled on the press through the pin 1; the blankholder 7, the first upper backing plate 3 and the second upper backi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com