Bender

A bending machine and frame technology, which is applied in the field of bending machines, can solve the problems of inability to guarantee accuracy, complex occupation of space, detachment of floating structure molds, etc., and achieve the effect of simple structure and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described below with reference to the drawings and embodiments.

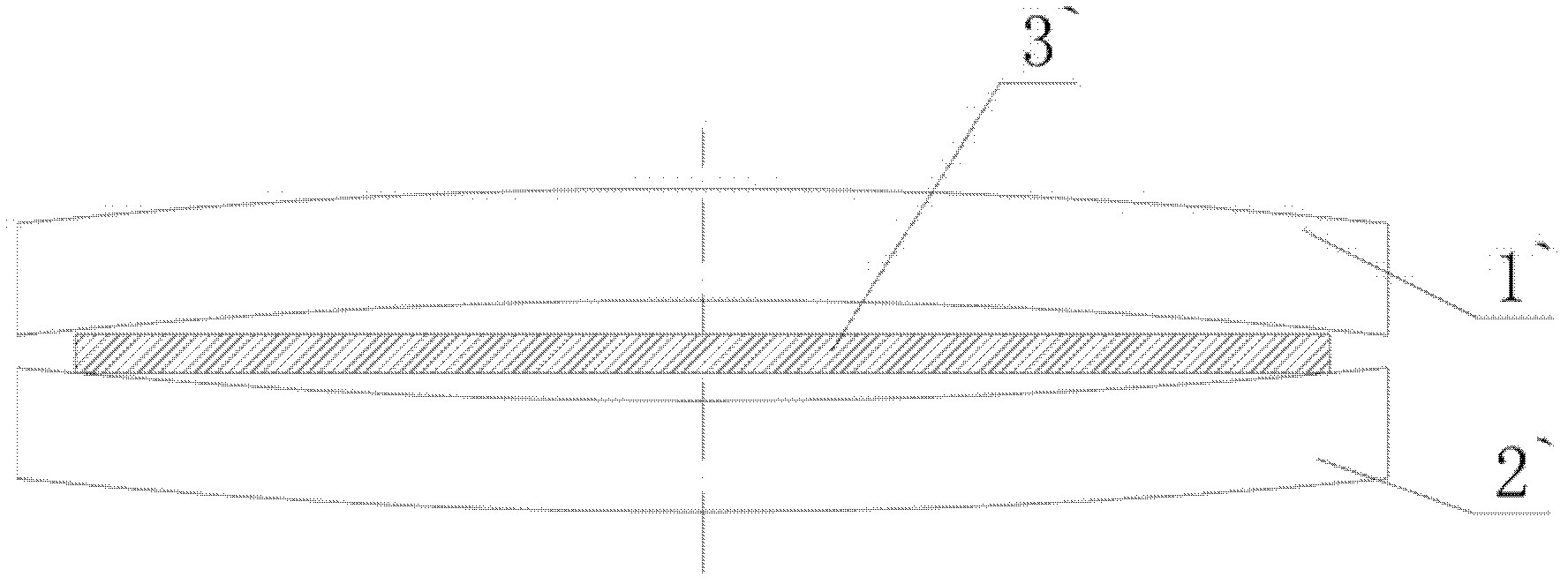

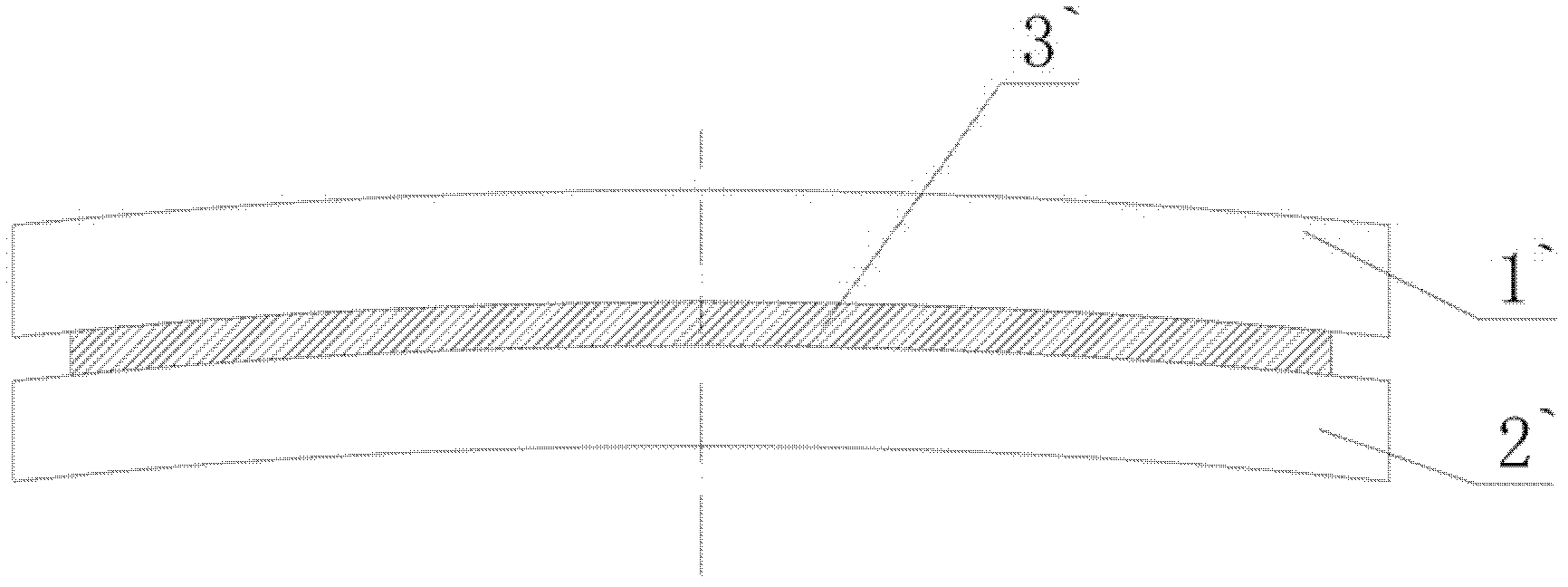

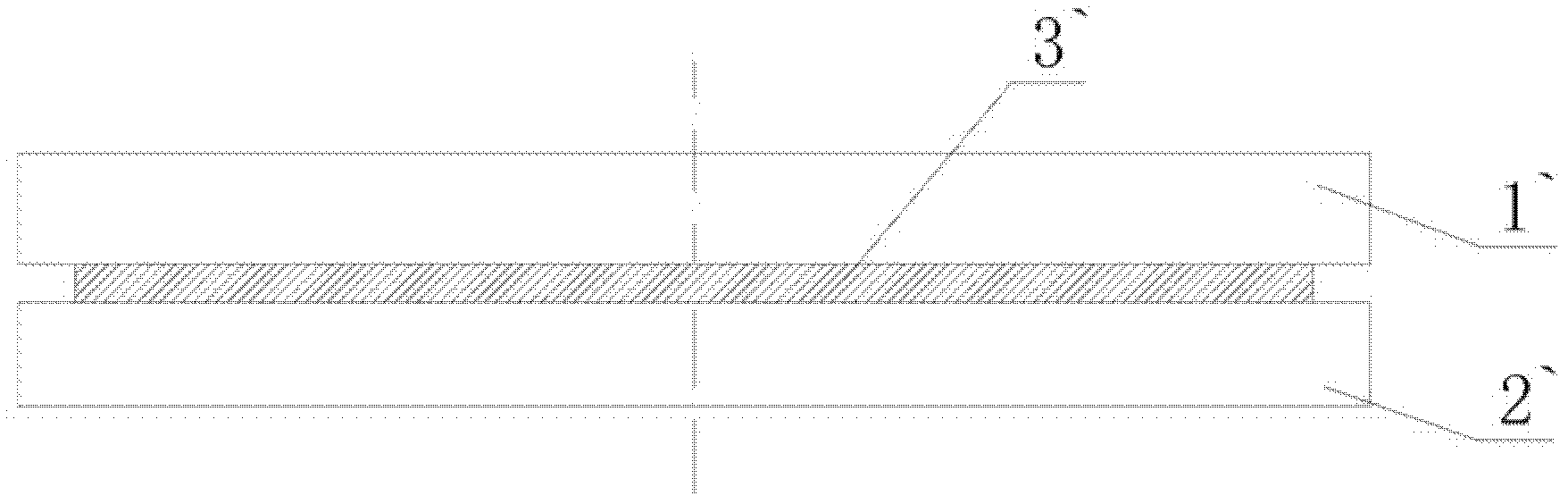

[0021] Such as Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the present invention discloses a bending machine with a bidirectional deflection automatic compensation function, including a frame 1, a sliding block 2 and a worktable 15, four screw drive mechanisms a, b, c, d and a sliding block 2. Fixed connection, screw drive mechanisms a and d are respectively arranged at both ends of the slider 2 in the horizontal direction, screw drive mechanisms b, c are set in the middle of the slider 2, and the workbench 15 is equipped with a deflection compensation device e, the workbench The panel 16 is placed on the deflection compensation device e, and the lower die 14 is installed on the workbench panel; the screw nuts of each screw drive mechanism are fixedly installed in the bearings, and the screw nuts are fixed on the frame through the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com