Photocatalyst for degrading organic dye waste water pollutants and preparation method thereof

A technology of photocatalysts and organic dyes, applied in water pollutants, chemical instruments and methods, energy wastewater treatment, etc., can solve the problems of affecting the effective area of catalysts, unfavorable photocatalyst efficiency, and limiting large-scale applications, etc., to achieve high commercial efficiency application prospects, high visible light absorption capacity, and loose application conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

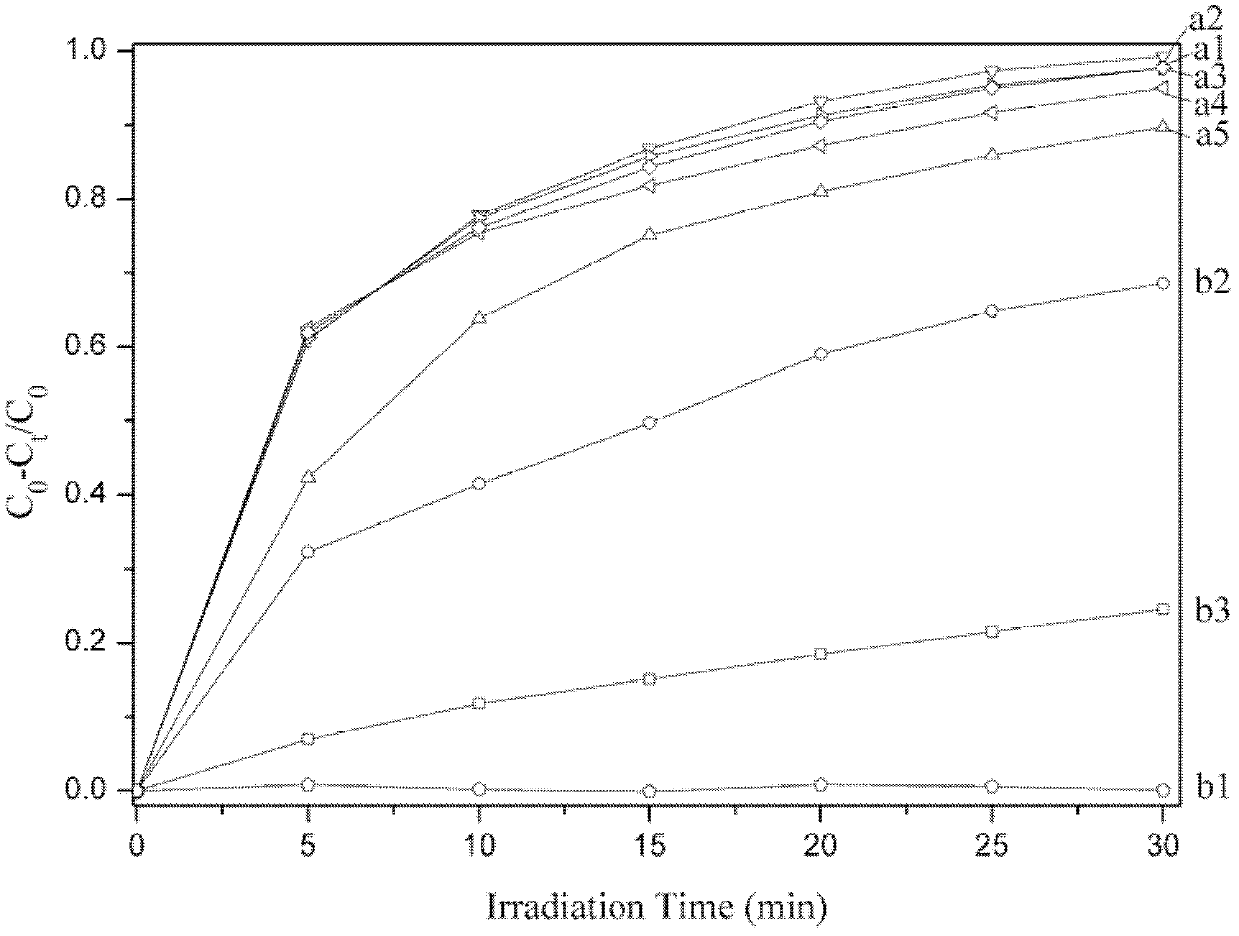

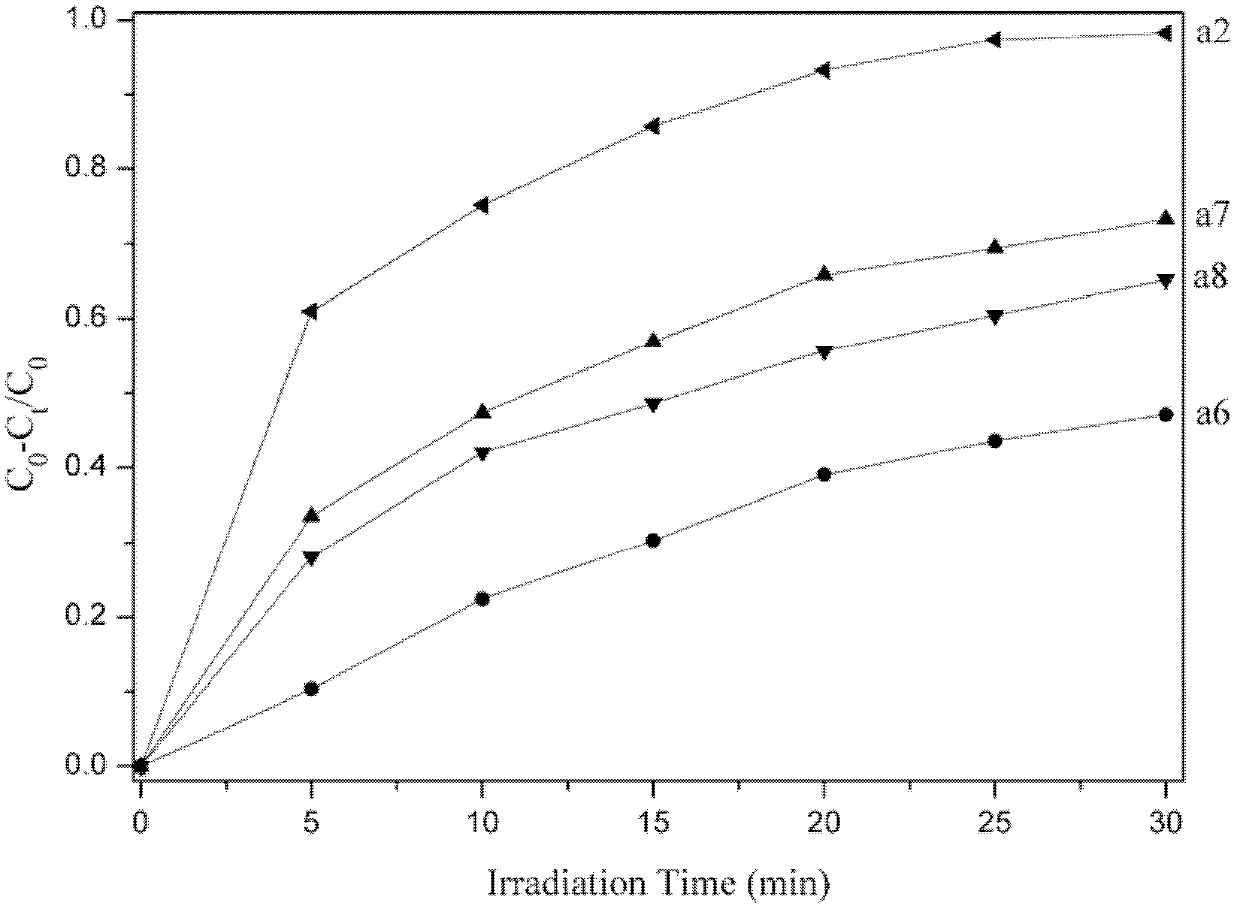

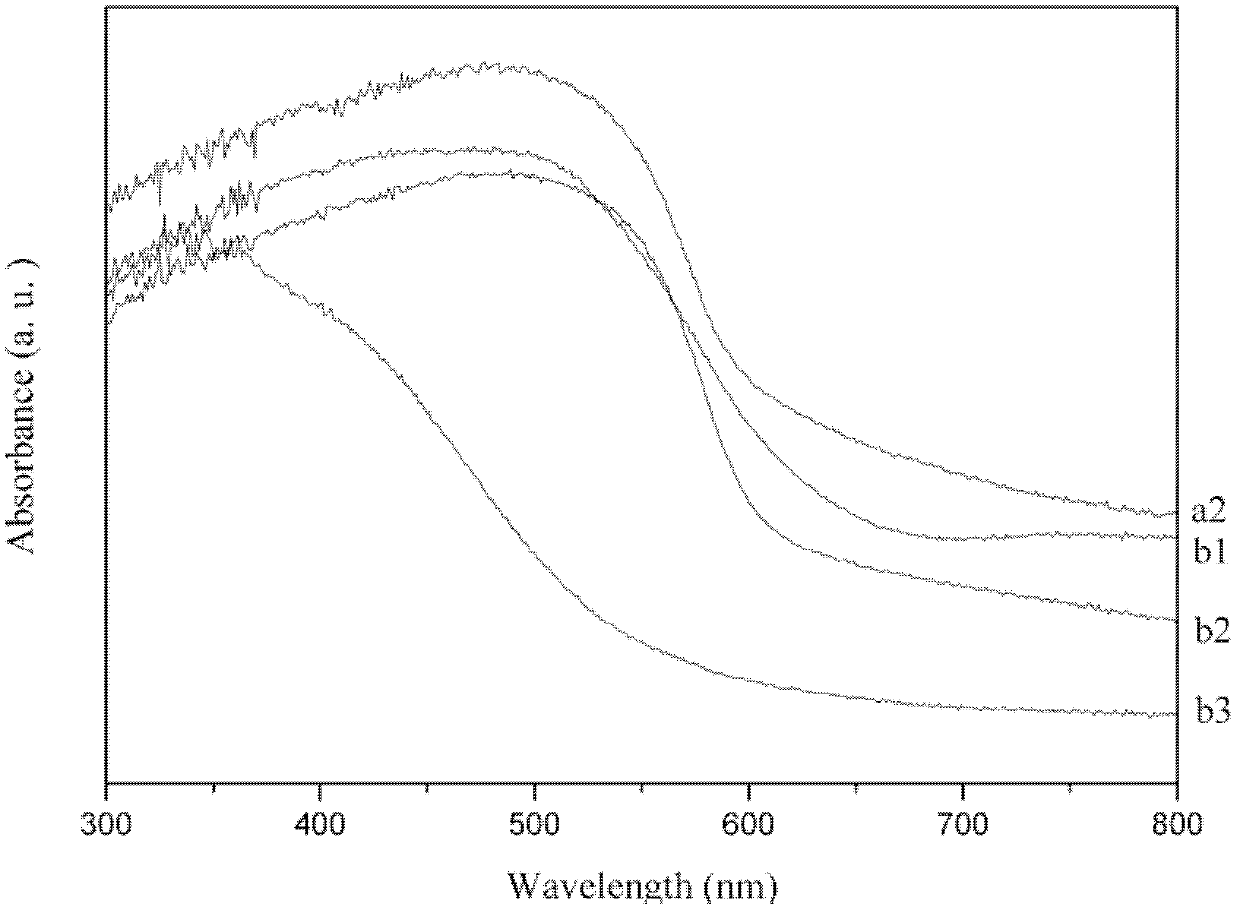

Embodiment 1

[0025] (1) Weigh 6.46g, 2.05g and 7.56g of ferric nitrate, magnesium nitrate and citric acid respectively, and dissolve them in 20ml of deionized water while stirring. Add about 20 ml of 30% ammonia water dropwise to the above mixed solution at a temperature of 60° C., adjust its pH value to 7, and continue stirring until a green gel is formed. The green gel was dried at 120°C for 24 hours to obtain a black precursor, and finally ground and calcined at 700°C for 3 hours to obtain reddish-brown magnesium ferrite powder.

[0026] (2) Weigh 2.40 g of sodium hydroxide, dissolve in 30 ml of deionized water with stirring in a water bath at 30° C., to obtain a sodium hydroxide solution. Weigh 10.10 g of silver nitrate, dissolve it in 30 ml of deionized water, stir and dissolve in a water bath at 30° C., and obtain a silver nitrate solution. Then, the silver nitrate solution was slowly added dropwise to the sodium hydroxide solution while stirring to form a yellow precipitate, which ...

Embodiment 2

[0029] (1) With the step of (1) in embodiment 1.

[0030] (2) With the step of (2) in embodiment 1.

[0031] (3) Weigh 0.002g of magnesium ferrite and 1.0g of silver vanadate, mix and grind them for 10min according to the mass ratio of magnesium ferrite / silver vanadate, and finally bake them at 300°C for 4 hours, and cool them naturally That is, MgFe calcined at 300°C 2 o 4 / Ag 3 VO 4 MgFe with a mass ratio of 0.002 2 o 4 / Ag 3 VO 4 Composite catalyst.

Embodiment 3

[0033] (1) With the step of (1) in embodiment 1.

[0034] (2) With the step of (2) in embodiment 1.

[0035] (3) Weigh 0.003g of magnesium ferrite and 1.0g of silver vanadate respectively, mix and grind them for 10min according to the mass ratio of magnesium ferrite / silver vanadate, and finally roast them at 300°C for 4 hours, and cool them naturally That is, MgFe calcined at 300°C 2 o 4 / Ag 3 VO4 MgFe with a mass ratio of 0.003 2 o 4 / Ag 3 VO 4 Composite catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com