Adhesive film

A technology of adhesive film and adhesive layer, which is applied in the direction of adhesives, film/sheet adhesives, adhesive products, etc., can solve the problems of adhesive residue, increased adhesive force, and difficult peeling, etc., to achieve adhesion Small increase in resultant force, small change in adhesive force, and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] The following examples are given to further illustrate the present invention. However, the present invention is not limited to the following Examples unless it deviates from the gist. In addition, the evaluation method of the physical property in the following Example and a comparative example is as follows.

[0083] (1) Crystal fusion heat and crystallization heat

[0084] Weigh about 5 mg of polyolefin resin, use a differential scanning calorimeter (DSC-60) manufactured by Shimadzu Corporation, raise the temperature to 200°C at a heating rate of 10°C / min, and keep it at 200°C for 5 minutes. After cooling down to 0°C at a cooling rate of 10°C / min, and then raising the temperature to 200°C at a rate of 10°C / min, the heat of fusion and heat of crystallization can be obtained from the graph.

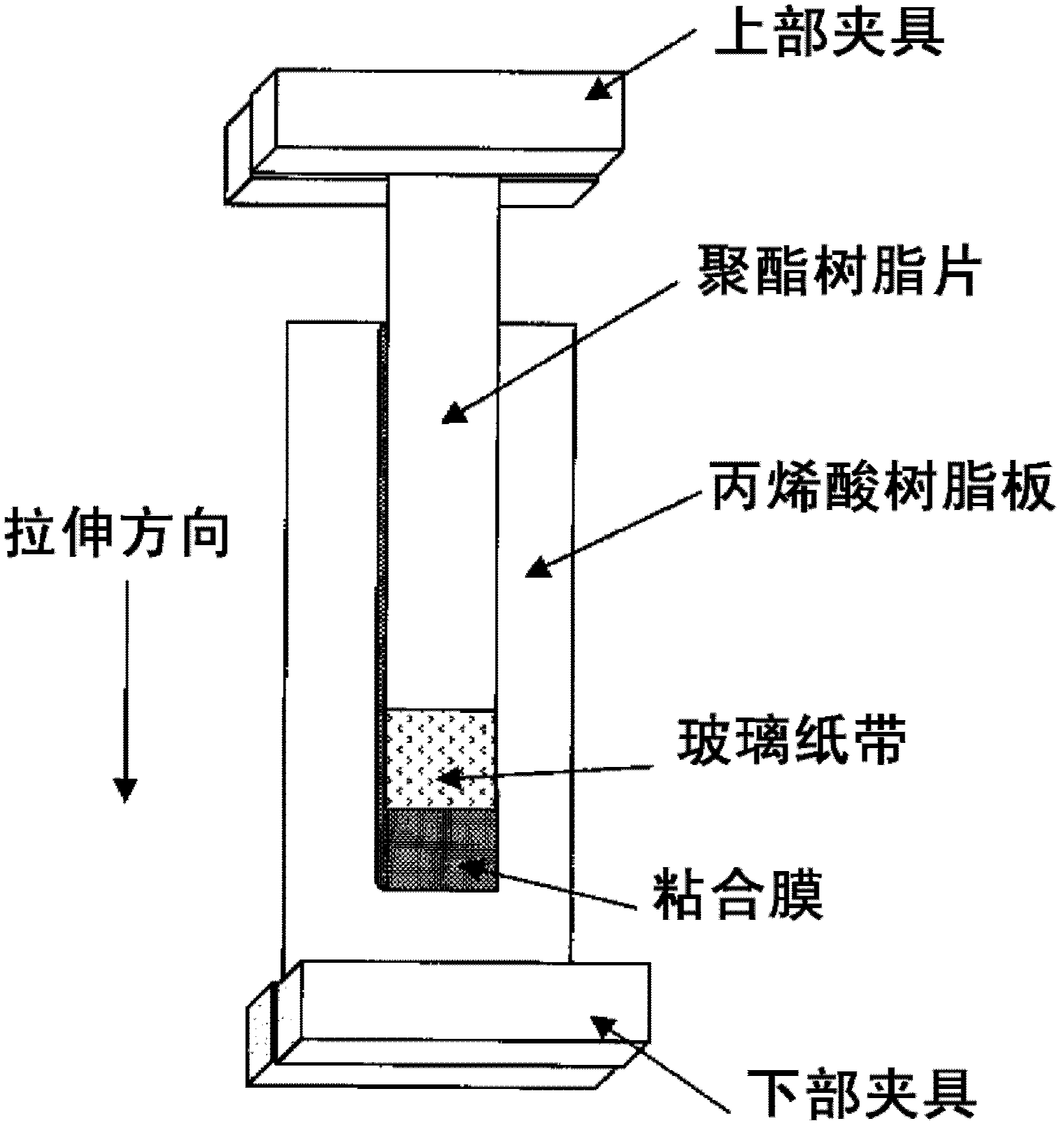

[0085] (2) Elastic modulus of the resin

[0086] According to the test method of JIS K7162, it measured under the following conditions.

[0087] Test piece: Type 1A

[0088] Be...

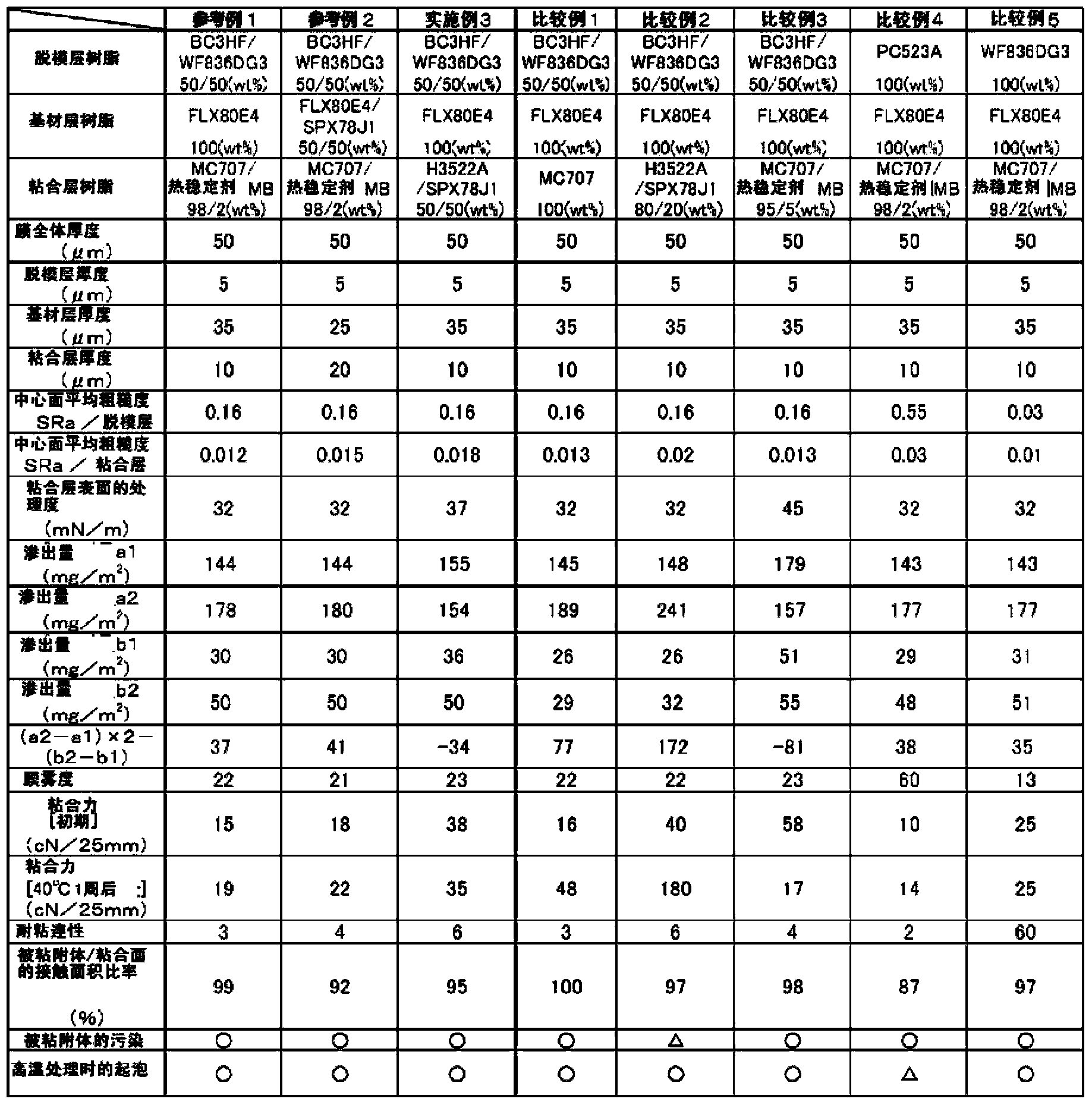

reference example 1

[0127] (Preparation of substrate layer)

[0128] 100 wt% of a homopolypropylene polymer (manufactured by Sumitomo Chemical: FLX80E4, tensile modulus: 1500 MPa) was melt-extruded with a 60 mmφ single-screw extruder (L / D: 22.4) to prepare a base layer.

[0129] (Preparation of adhesive layer)

[0130] 98wt% olefin-based elastomer (manufactured by Mitsubishi Chemical: Zealous MC707) and 2wt% heat stabilizer masterbatch (MB) containing 50000ppm Irganox1076 were melt-extruded with a 45mmφ twin-screw extruder (L / D: 19). became the adhesive layer.

[0131] (production of release layer)

[0132] Melt extrusion of 50wt% propylene-ethylene block copolymer (POLYPRO BC3HF Japan) and 50wt% propylene-ethylene random copolymer (manufactured by Sumitomo Chemical: WF836DG3) with a 65mmφ single-screw extruder (L / D: 25), A release layer was made.

[0133] (film production)

[0134] In the state where the base material layer, adhesive layer, and release layer are melted by each extruder, a 3...

reference example 2

[0137] In addition to making the resin of the base layer propylene-1-butene copolymer (manufactured by Sumitomo Chemical: SPX78J1, tensile modulus: 530MPa) 50wt% and a homopolypropylene polymer (manufactured by Sumitomo Chemical: FLX80E4, tensile modulus : 1500 MPa) Except for 50 wt%, a film was produced in the same manner as in Reference Example 1. The film also forms a smooth adhesive layer, has adhesiveness at room temperature, does not have uneven contact between the adherend and the adhesive layer, and has a small increase in the adhesive force after sticking to the adherend. Excellent, no blocking between the release layer and the adhesive layer, and a film with good handling properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com