Method and device for producing welded connections

A welding connection and welding device technology, applied in welding equipment, transportation and packaging, application, etc., can solve the problems of difficult thin steel wire, expensive surface, increased steel consumption, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

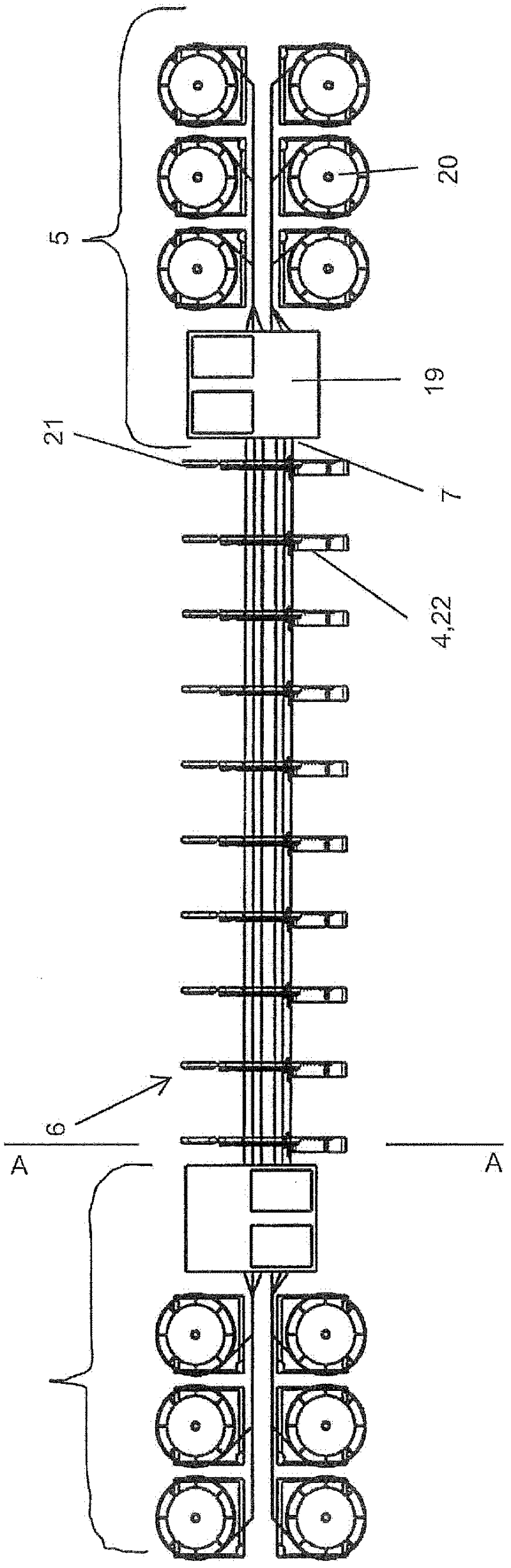

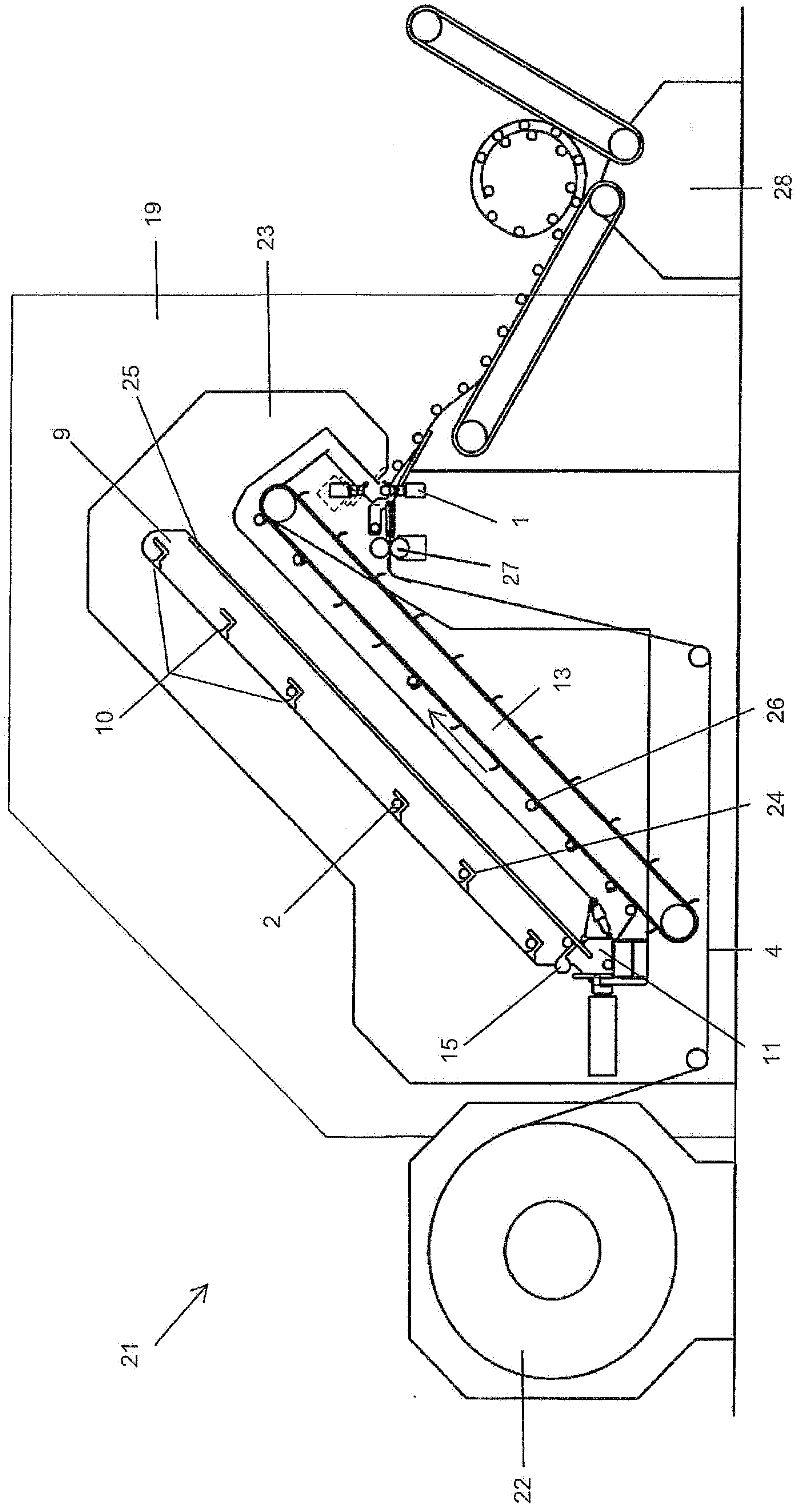

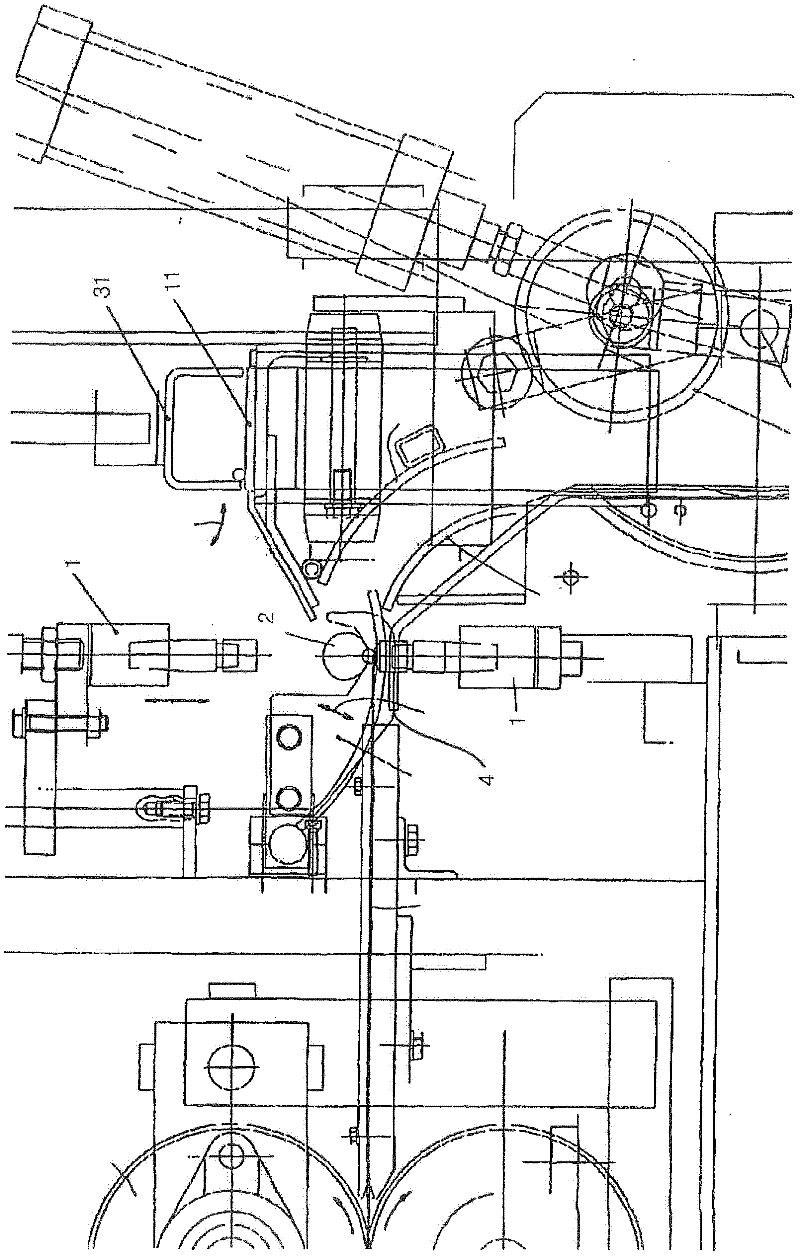

[0024] figure 1 A top view of a machine for manufacturing uniaxially reinforced reinforcement mesh mats according to the invention is shown. The overall length of the machine is about 30 meters, of which 15 meters are used for the mat machine 6. The left side and the right side of the mesh pad machine 6 show the pre-set bins 5 for reinforcing steel bars 2, which in this embodiment consist of a steel bar forming machine 19, which will be wound on a steel coil 20 with Wires of different diameters are drawn, straightened and shortened. Here, according to the invention, the steel coil 20 can carry steel wires with a diameter of up to 20 mm. Due to the mechanical deformation of the steel wire during the bar forming process, its suitability for the method according to the invention may be reduced. In this case, on the right side and / or the left side of the mesh pad machine 6, a pre-set bin 5 in the form of a reinforcement bin is set, wherein the pre-bundled reinforcing steel bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com