Combined type transformer for photovoltaic power generation

A combined transformer and photovoltaic power generation technology, applied to transformers, fixed transformers, circuits, etc., can solve the problems of long maintenance and replacement requirements, increased fuel tank volume, increased oil consumption, etc., to ensure safe and normal operation, replacement, etc. Simplified work and reduced fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

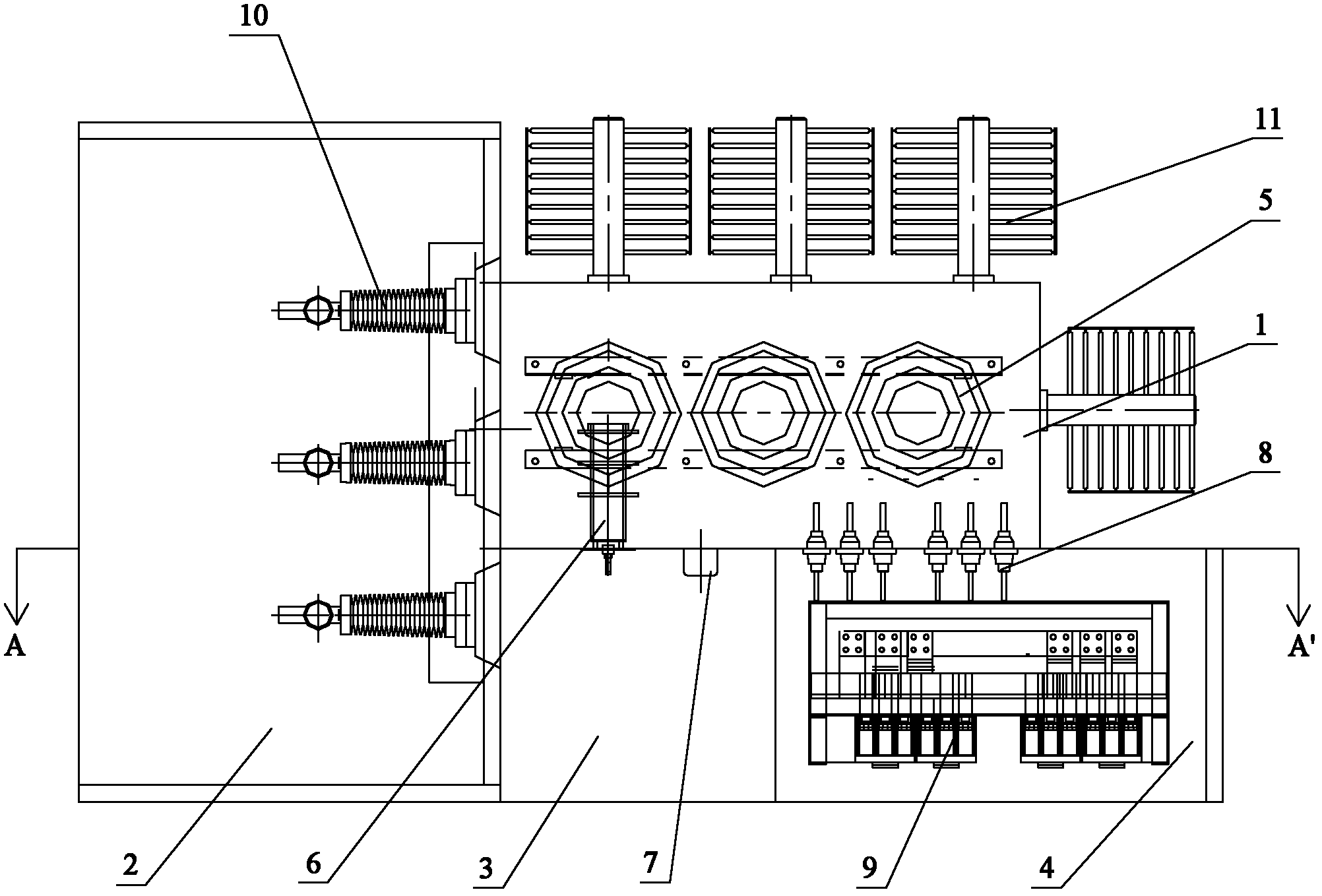

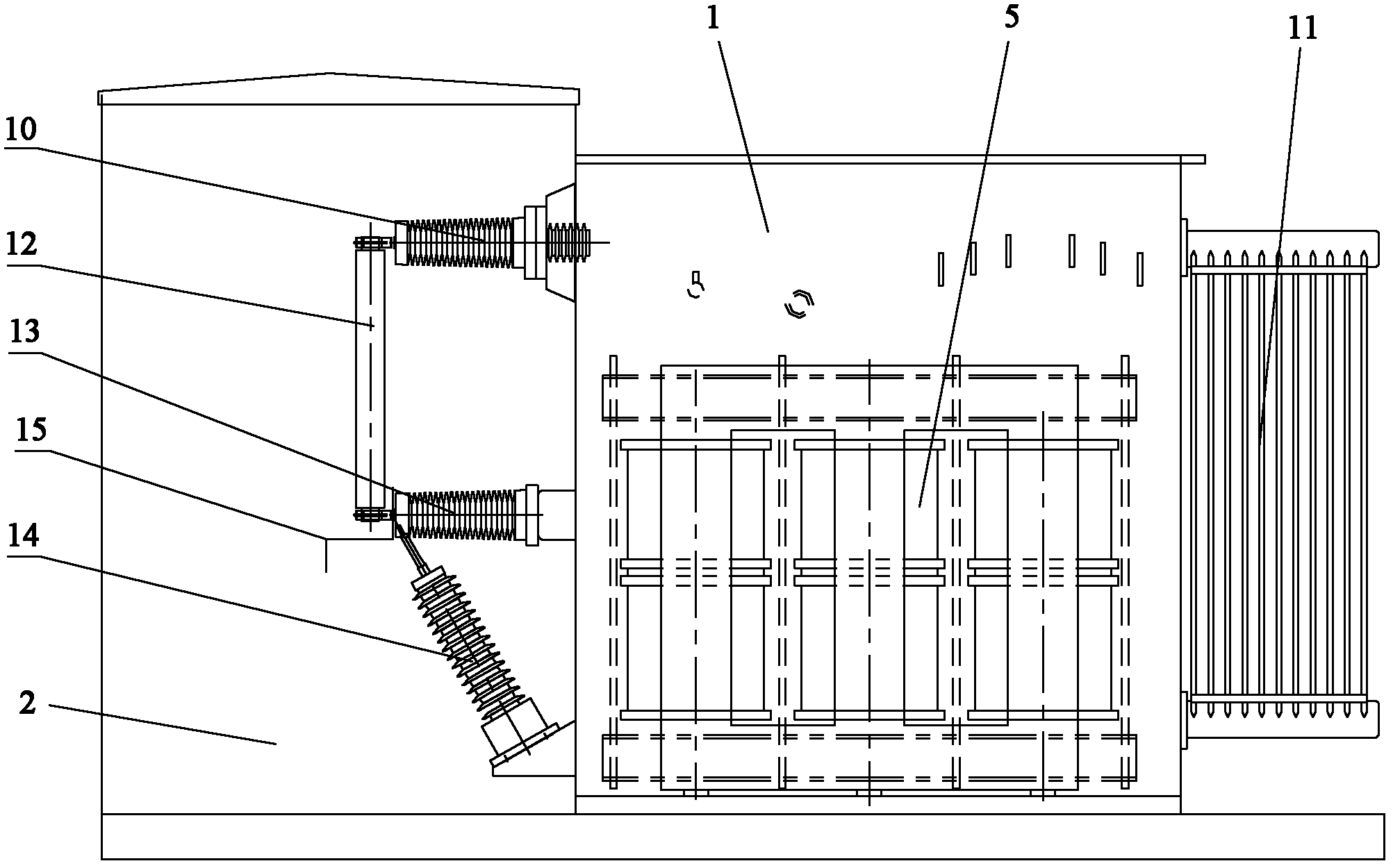

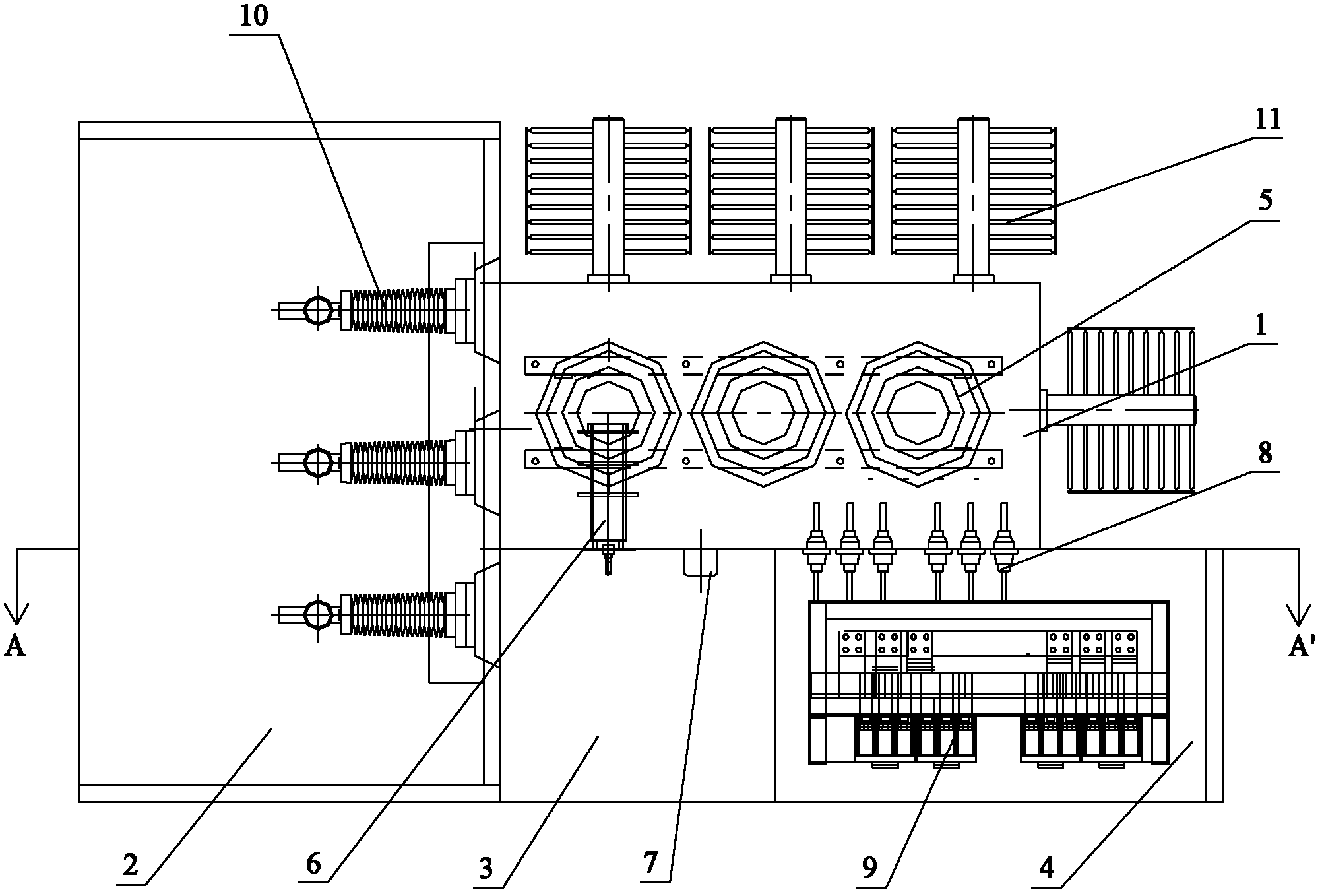

[0020] Such as figure 1 with figure 2 As shown, a combined transformer for photovoltaic power generation includes a transformer oil tank 1; the left side of the transformer oil tank 1 is provided with a high-voltage cable room 2, and the front side is provided with a high-voltage operation room 3 and a low-voltage operation room 4; a high-voltage cable room 2, a high-voltage The operating room 3 and the low-voltage operating room 4 are respectively made into a box body, and are connected with the transformer oil tank 1 through bolts to form a whole.

[0021] The transformer oil tank 1 is provided with an axial double-split three-phase transformer 5 and a high-voltage load switch 6 and a tap changer 7 connected to the high-voltage side of the axial doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com