Method by adopting impulse airflow method to grow gallium phosphide (GaP) current extension layer

A technology of current spreading layer and pulsed air flow, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problems of affecting the efficiency and life of LED, reducing light extraction efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

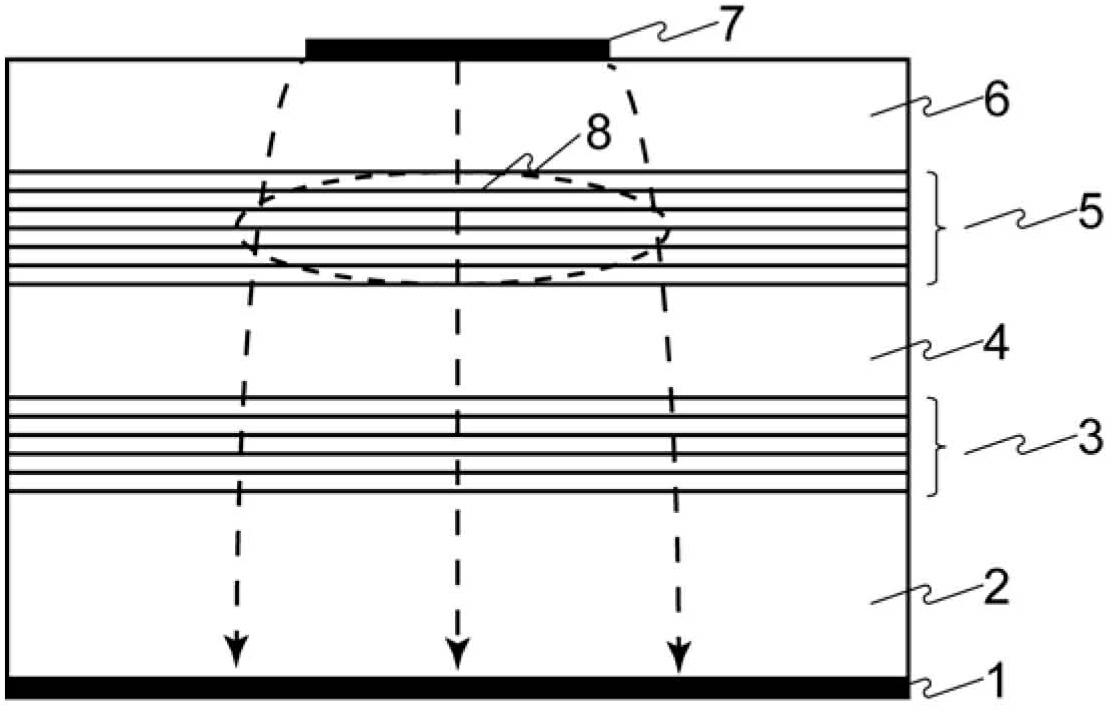

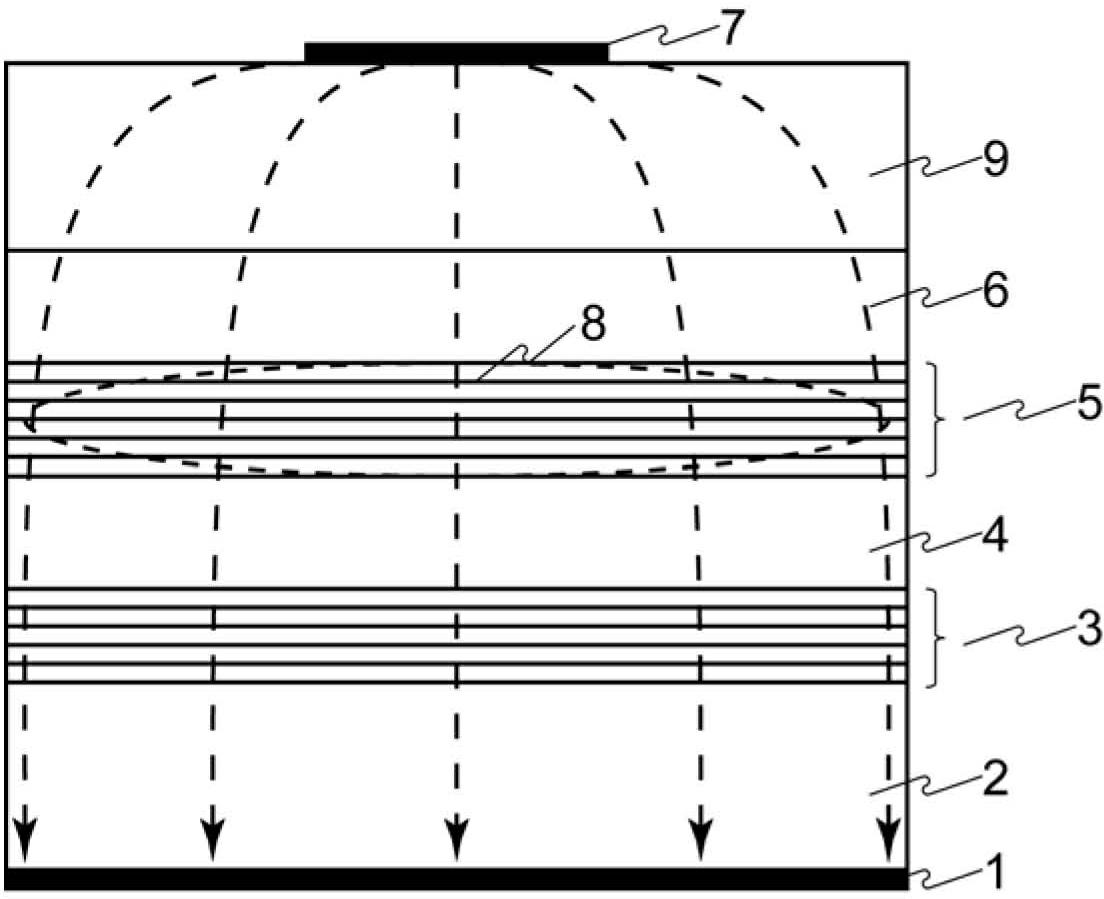

[0020] Such as figure 2 As shown, a distributed Bragg reflection layer 3 , a first-type epitaxial layer 4 , a light-emitting layer 5 and a second-type epitaxial layer 6 are sequentially grown on a GaAs substrate 2 by MOCVD. The distributed Bragg reflection layer 3 is composed of a combination of AlAs, GaAs, AlGaAs, AlInP, GaInP, and AlGaInP. The first-type epitaxial layer 4 is composed of AlAs, GaAs, AlGaAs, AlInP, GaInP, AlGaInP, and is doped with first-type impurities. The light emitting layer 5 is composed of AlAs, GaAs, AlGaAs, AlInP, GaInP, AlGaInP. The second-type epitaxial layer 6 is composed of AlAs, GaAs, AlGaAs, AlInP, GaInP, AlGaInP, and is doped with second-type impurities.

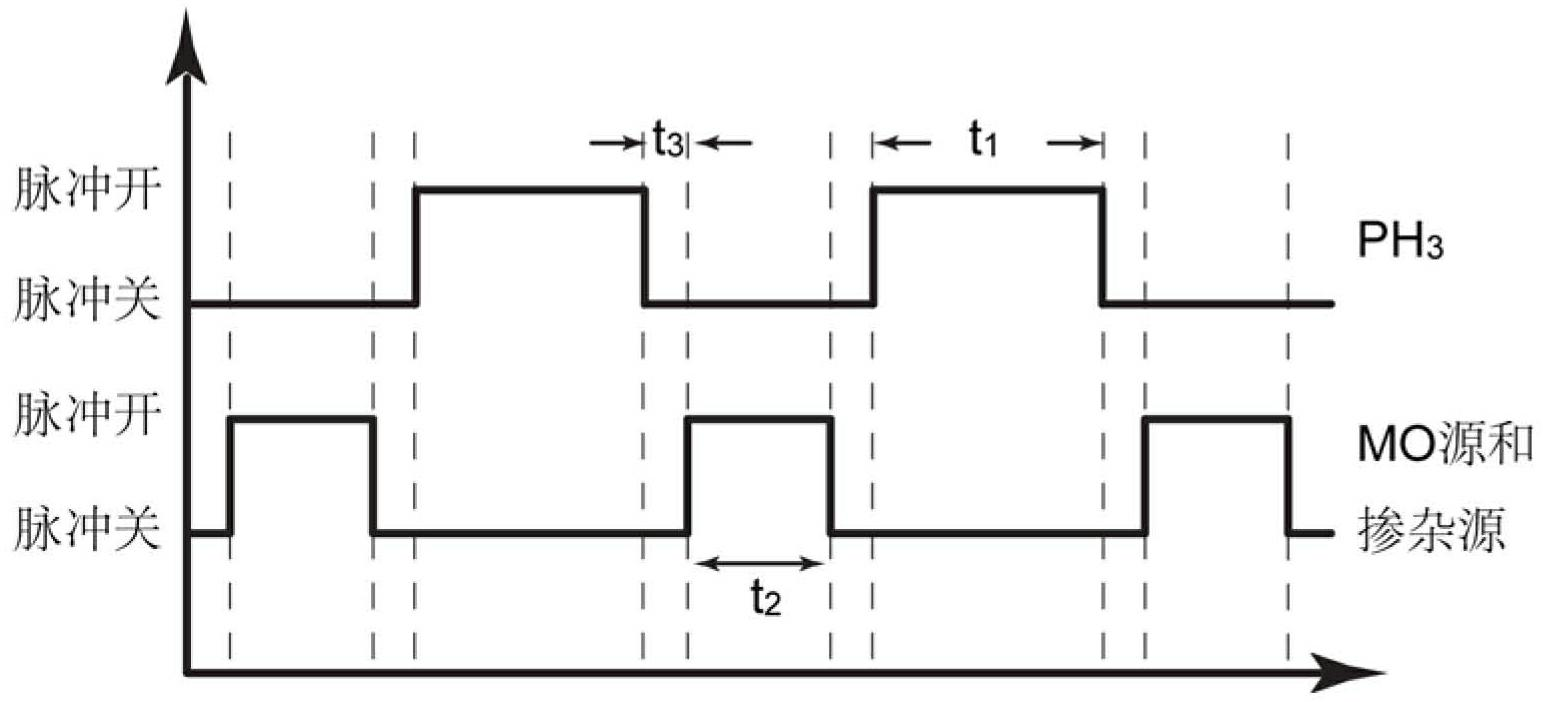

[0021] On the second-type epitaxial layer 6, the metal-organic compound source (MO source) containing gallium atoms, phosphine (PH 3 ) and the dopant source are pulsed into the MOCVD reaction chamber. The GaP current spreading layer 9 is grown by using the first pulse working mode or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com