Thinned image capture module and manufacturing method thereof

An image capture and module technology, which is applied in image communication, radiation control devices, color TV components, etc., can solve problems such as gold wire tearing, displacement, and adhesion difficulties, so as to solve alignment difficulties and prevent interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

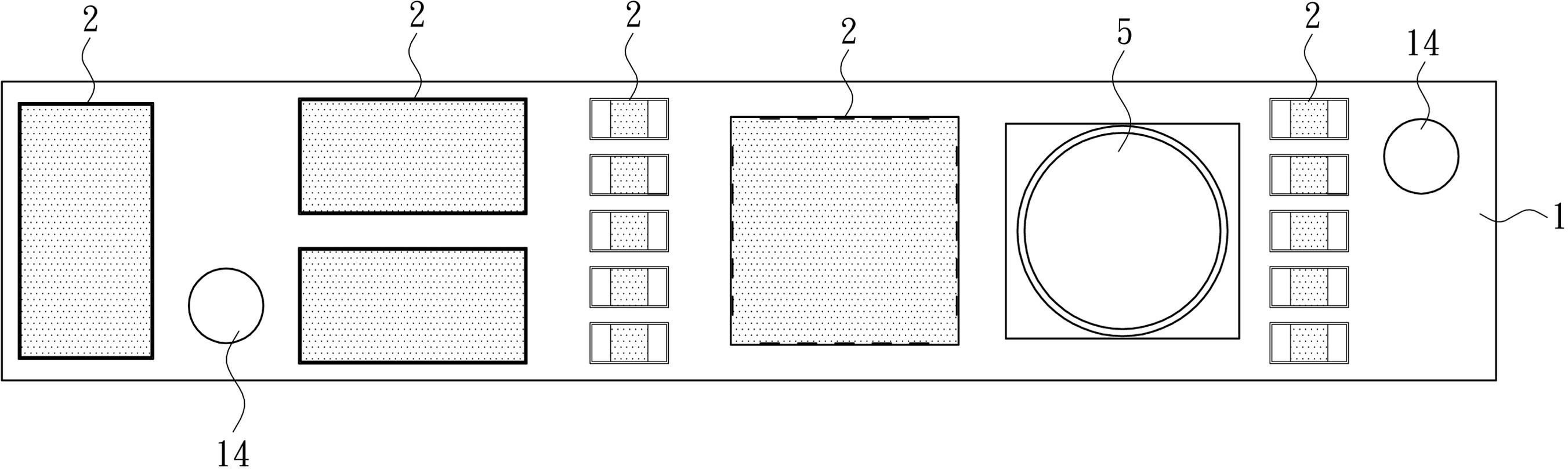

[0056] Please refer to Fig. 1 to Fig. 13, the structure and manufacturing method of the selected embodiment of the present invention are shown in the figure, which is for illustration only, and is not limited by this embodiment in patent application.

[0057] The present invention provides a thinned image capture module and a manufacturing method thereof. Firstly, the structure of the image capture module of this embodiment is described.

[0058] As shown in Figures 1 to 3, the image capture module of this embodiment includes a printed circuit board 1, a number of electronic components 2, a photosensitive element 3, a light-transmitting glass 4 and a lens 5, wherein: As shown in Figure 3, the printed circuit board 1 has soldering pads 10 on the front surface, the soldering pads 10 mentioned above are connected to the circuit (not shown in the figure) in the printed circuit board 1, and the aforementioned electronic components 2 are correspondingly connected to each other. on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com