Tunnel vacuum drying equipment

A technology of vacuum drying equipment and tunnels, which is applied in the direction of drying solid materials, progressive dryers, lighting and heating equipment, etc., and can solve the problems of not saving energy, taking a long time, and not being fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

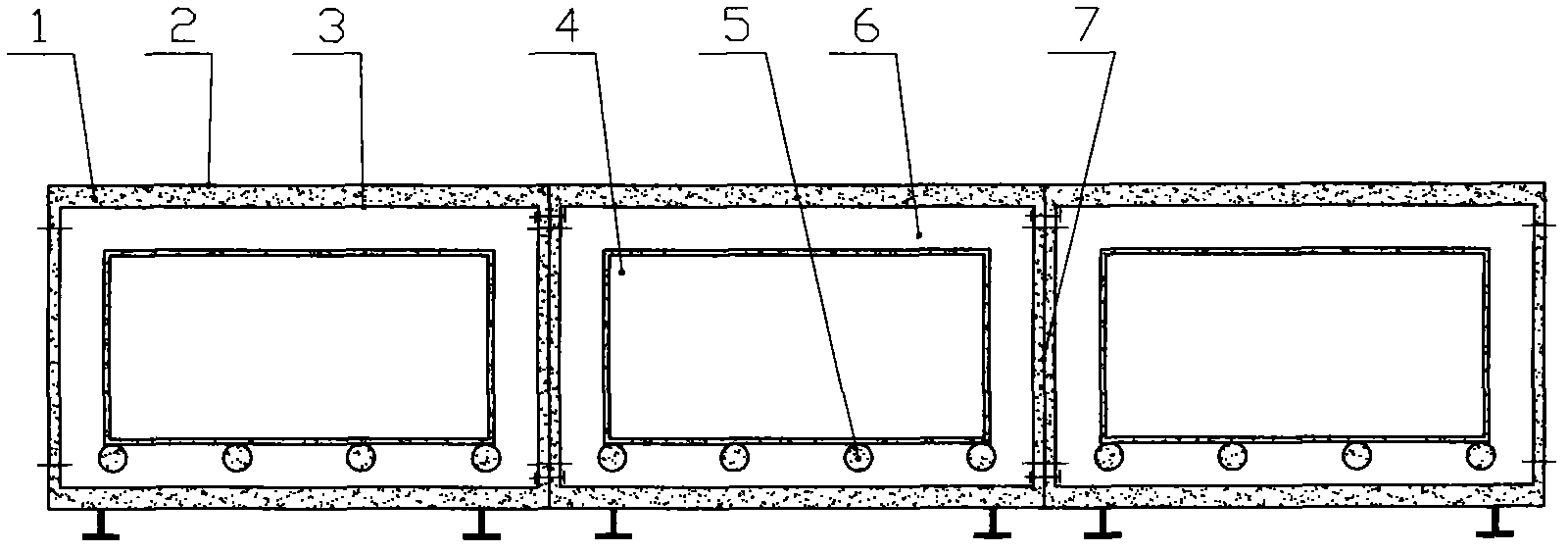

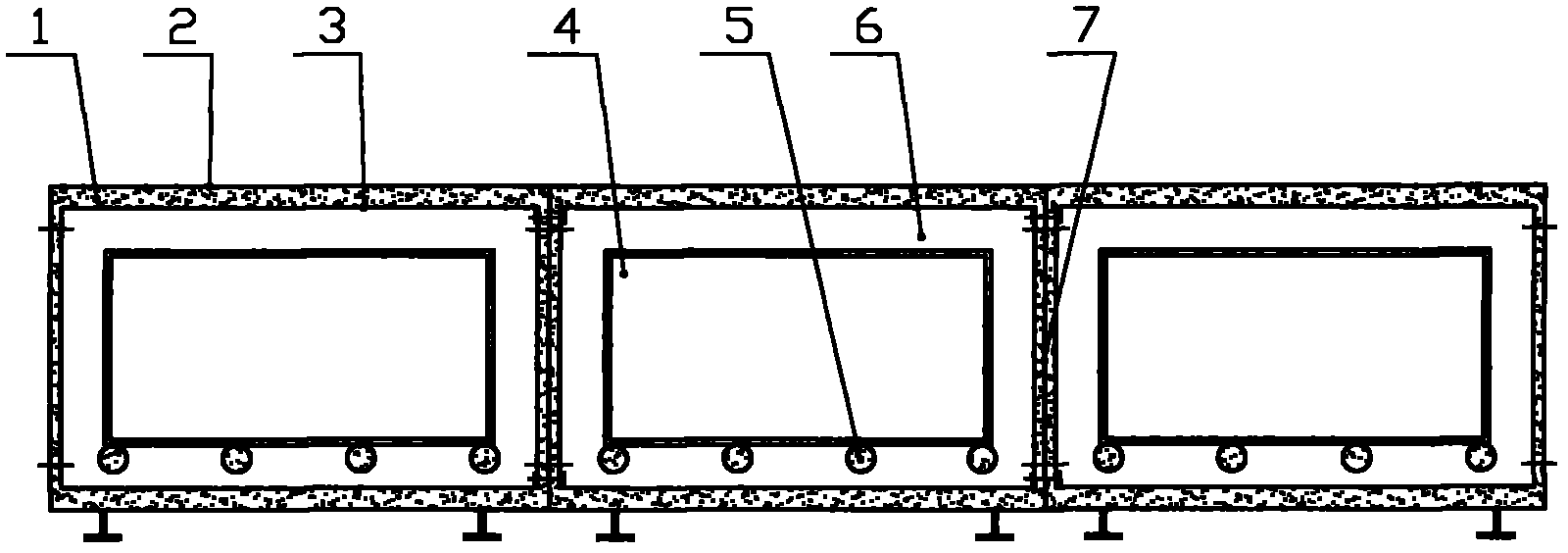

[0011] A tunnel vacuum drying equipment, such as figure 1 As shown, it includes: an outer shell 2, an inner tank 3 is fixedly connected inside the outer shell 2, an insulating material 1 is filled between the inner tank 3 and the outer shell 2, an isolation door 7 is connected to the two ends of the outer shell 2 and the inner tank 3, and the inner cavity 6 is equipped with an air inlet and outlet, a steam heating device and a condensed water cooling device, and a temperature control device is installed on the inner cavity 6, and a roller 5 is connected to the inner cavity 6, and a vacuum box 4 is connected to the roller 5. The box body 4 is equipped with a sealed door, and the vacuum box body 4 is fixedly connected with a pipeline, and a valve is installed on the pipeline; two or more tunnel vacuum drying equipment are used together.

[0012] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com