Gas-solid separator of recirculating fluidized bed boiler and boiler comprising same

一种气固分离器、循环流化床的技术,应用在流化床燃烧设备、分离方法、弥散粒子分离等方向,能够解决锅炉启停慢、飞灰量大、增加维修费用等问题,达到延长使用寿命、提高综合能效、减少烟尘排放的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

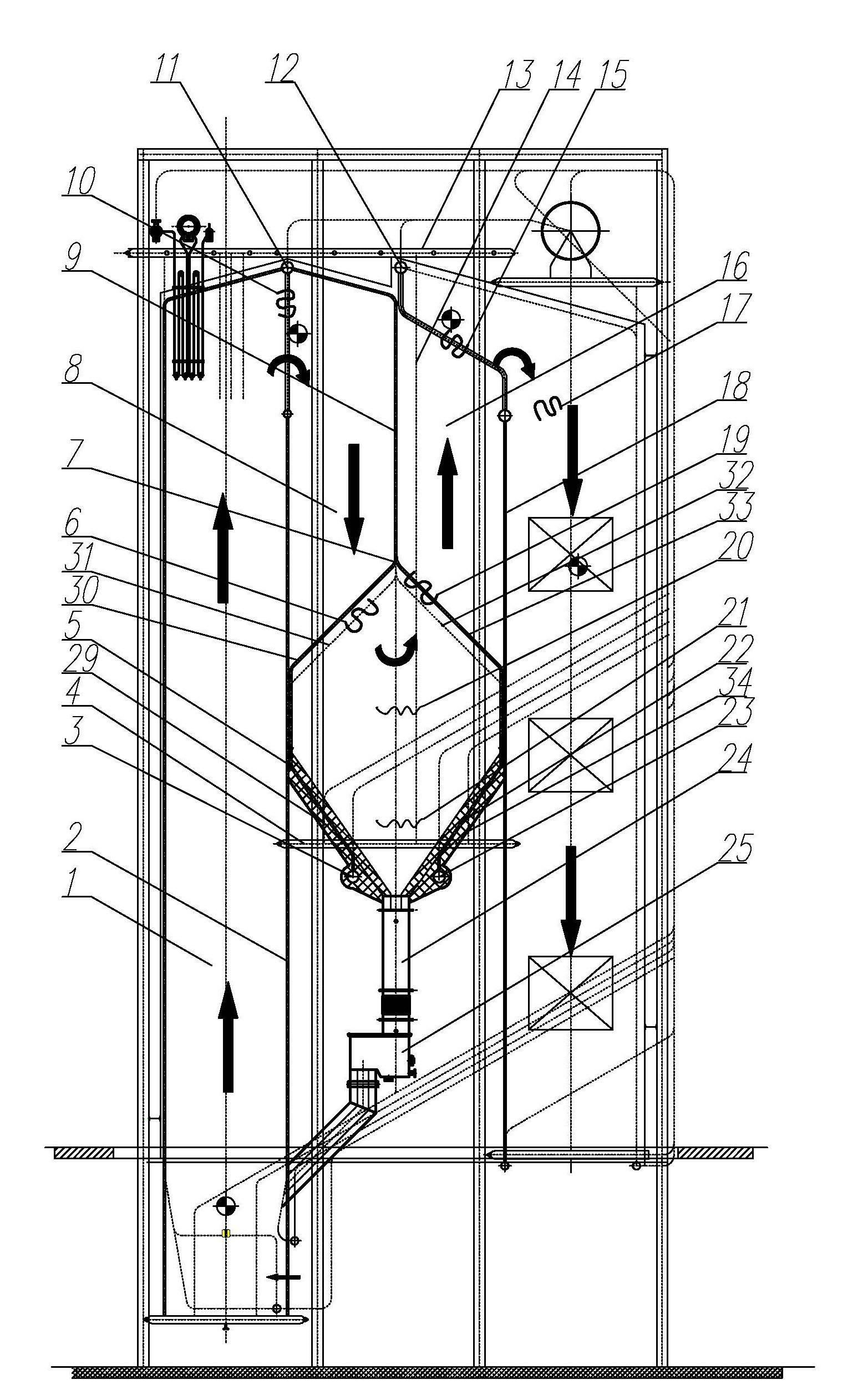

[0049] Embodiment 1: In this embodiment, the gas-solid separator of the circulating fluidized bed boiler is introduced together with the circulating fluidized bed boiler using the gas-solid separator. In this embodiment, only the gas-solid separation of the boiler is involved. The structure of the boiler and other structures of the boiler can adopt the conventional boiler structure or the new boiler structure, and the other parts of the boiler will not be described in detail. Please refer to the attached figure 1, in this embodiment, it mainly includes four major parts, namely boiler furnace 1, gas-solid separator, shaft 17 and return device (return device described in this embodiment is return valve 25), gas-solid separator It is arranged at the rear of the furnace 1 and the front of the shaft 17. In this embodiment, the gas-solid separator includes a downgoing flue 8 and an upgoing flue 16 separated from front to back by the lower and upper turning membrane screen 9 leading...

Embodiment 2

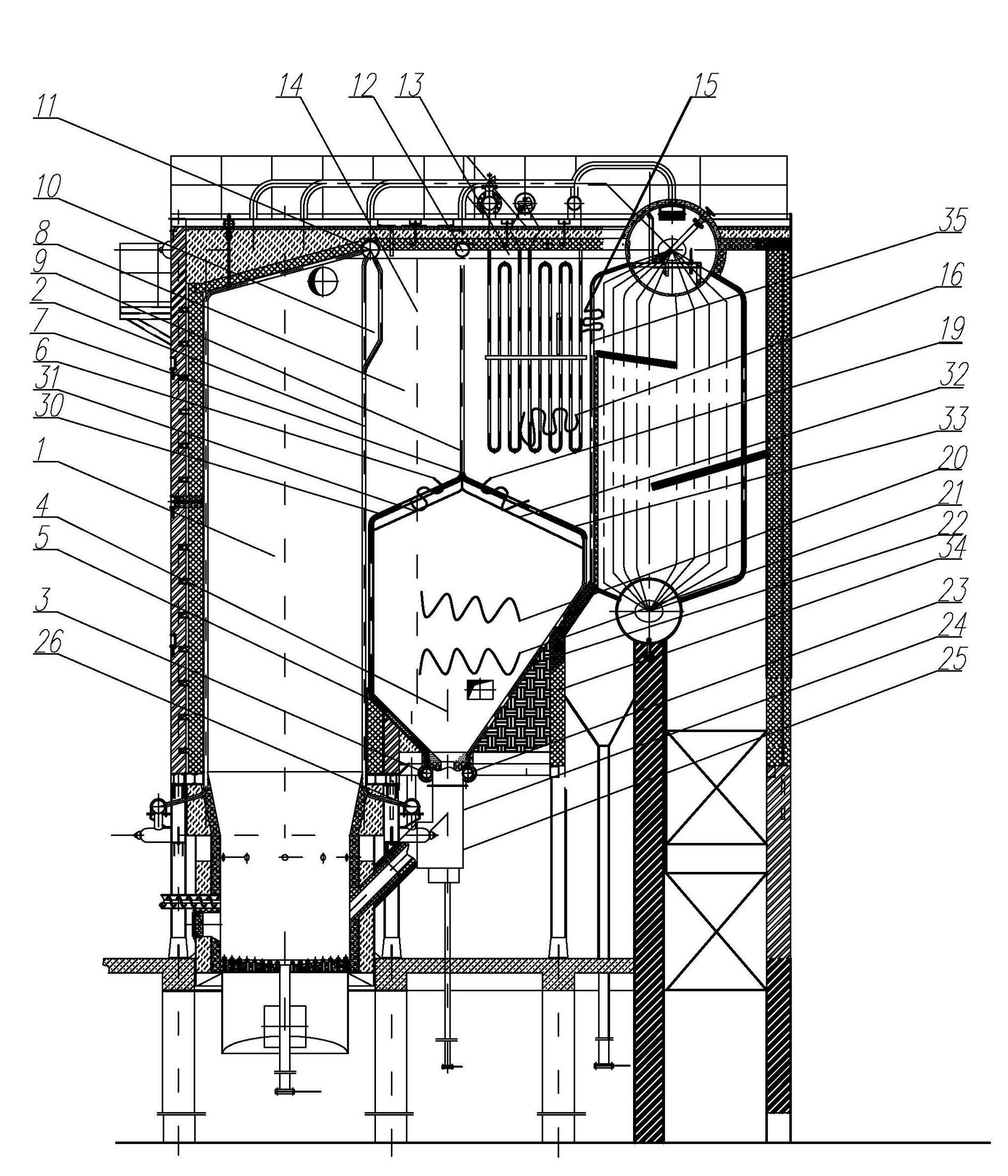

[0052] Example 2: See attached figure 2 In this embodiment, the tube bundles of the flue gas inlet 6 and the flue gas outlet 19 of the turning passage can be asymmetrical or symmetrical, and the front and rear wall tubes of the silo can be asymmetrical or symmetrical. The basic structure of this embodiment is similar to Embodiment 1. The main difference between this embodiment and Embodiment 1 is that the boiler in this embodiment is a horizontal double-drum boiler, and the shaft is at the lower end of the convection tube bundle, which is less than or equal to half shaft. The working process of the separator in this embodiment is the same as in Embodiment 1.

[0053] The flow velocity of the dense-phase zone and the dilute-phase zone of the boiler in this embodiment: higher than that of the fluidized bed boiler and lower than that of the low circulation rate fluidized bed boiler, the average flow velocity of the gas-solid separator downflow flue and upflow flue is 3m / s to 4m...

Embodiment 3

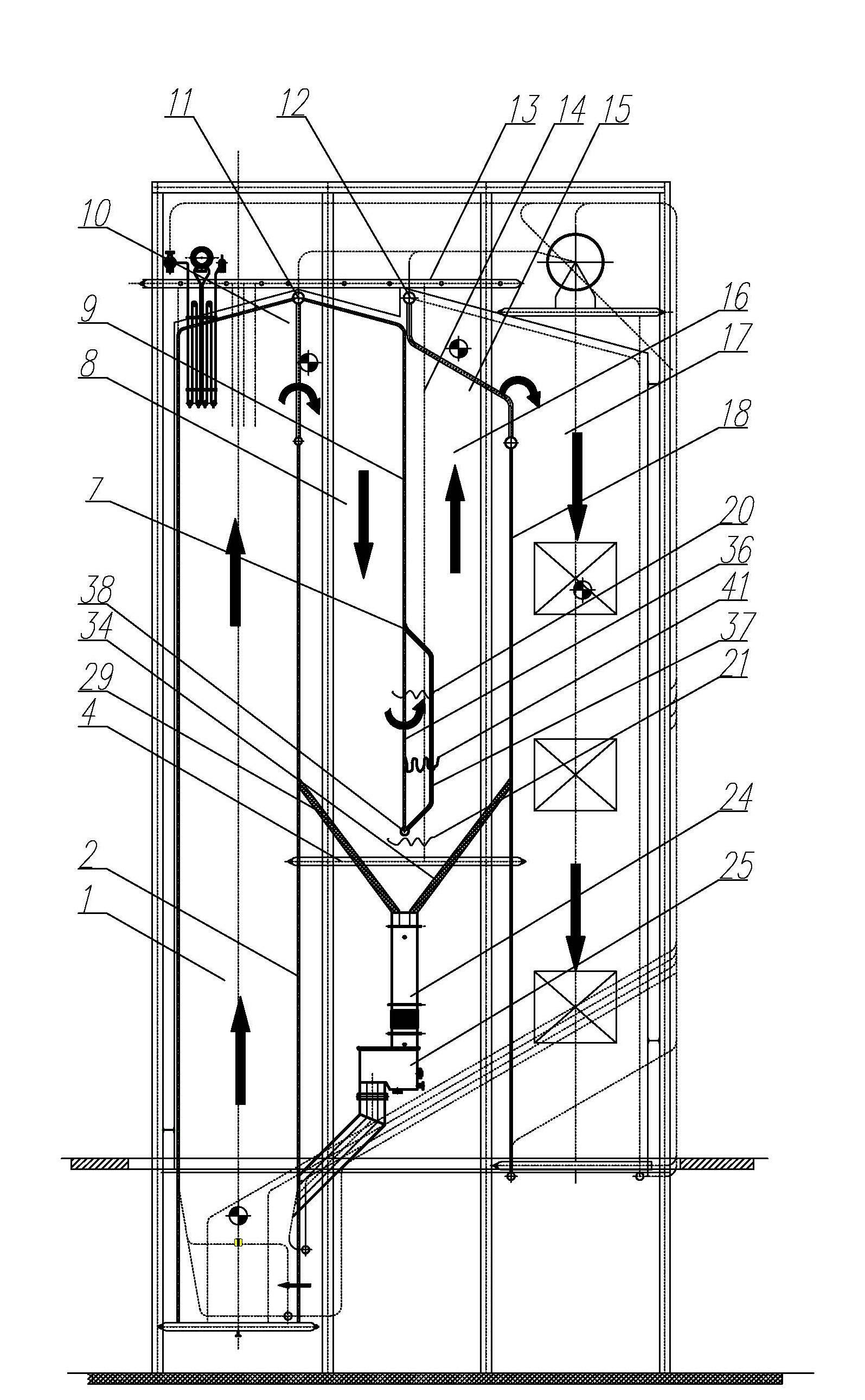

[0054] Example 3: See attached image 3 , the basic structure of this embodiment is the same as that of Embodiment 1. The difference between this embodiment and Embodiment 1 is that the front row of tube bundles 36 and the rear row of tube bundles 37 are formed on the lower turning channel of the membrane screen bifurcation 7 or Add tube rows and bundles backwards. The specific structure is: the lower part of the membrane screen bifurcation 7 is divided into two rows (or three to five rows of tube bundles are arranged in sequence backwards, and the longitudinal spacing and number of tube rows are determined based on the selection of the flue gas flow rate) , the lower end of the front tube bundle 36 communicates with the upper part of the lower horizontal header 38 of the tube bundle, and the rear tube bundle 37 (all tube bundles from the front tube bundle 36 are defined as the rear tube bundle) is a distance away from the front tube bundle 36, and its lower end is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com