Pipeline compensator

A pipeline compensator and ring pipe technology, applied in the field of compensators, can solve problems such as corrosion cracking, compensator damage, guide sleeve wear, etc., and achieve the effects of prolonging service life, improving service life and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

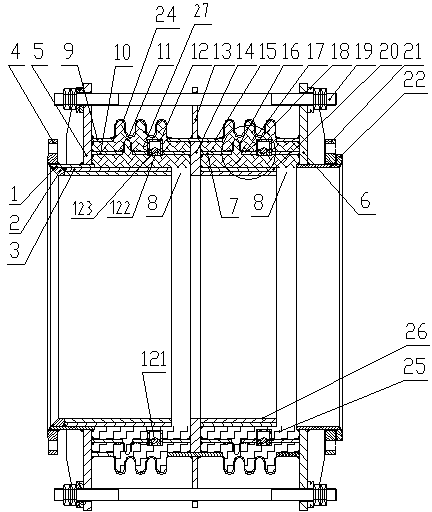

[0023] Such as figure 1 , 2 As shown, a pipeline compensator provided by the present invention first declares that the medium flow direction of the pipeline compensator is figure 1 From left to right in the figure, so the left side in the figure is called the front side or the front, and the right side in the figure is the rear side or the rear. The installation direction of the pipeline compensator is figure 1 In the reading direction, the upper side in the figure must be installed upwards.

[0024] Depend on figure 1 It can be seen that the pipeline compensator has a front ring plate 5 and a rear ring plate 6 connected in series by several large pull rods 19. The inner end of the front ring plate 5 is welded to a front connecting pipe 1, and the front connecting pipe 1 is connected with a fixing method. Lan 4, the inner end of the rear ring plate 6 is welded with a rear connecting pipe 22, and the rear connecting pipe 22 is connected with a loose flange 21; The first rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com