Minitype turbofan engine

A turbofan engine, micro technology, applied in the direction of machine/engine, jet propulsion, etc., can solve the problems of increased wear and tear of parts, large combustion chamber space, inability to start by itself, etc., to achieve low noise, small combustion chamber space, and efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

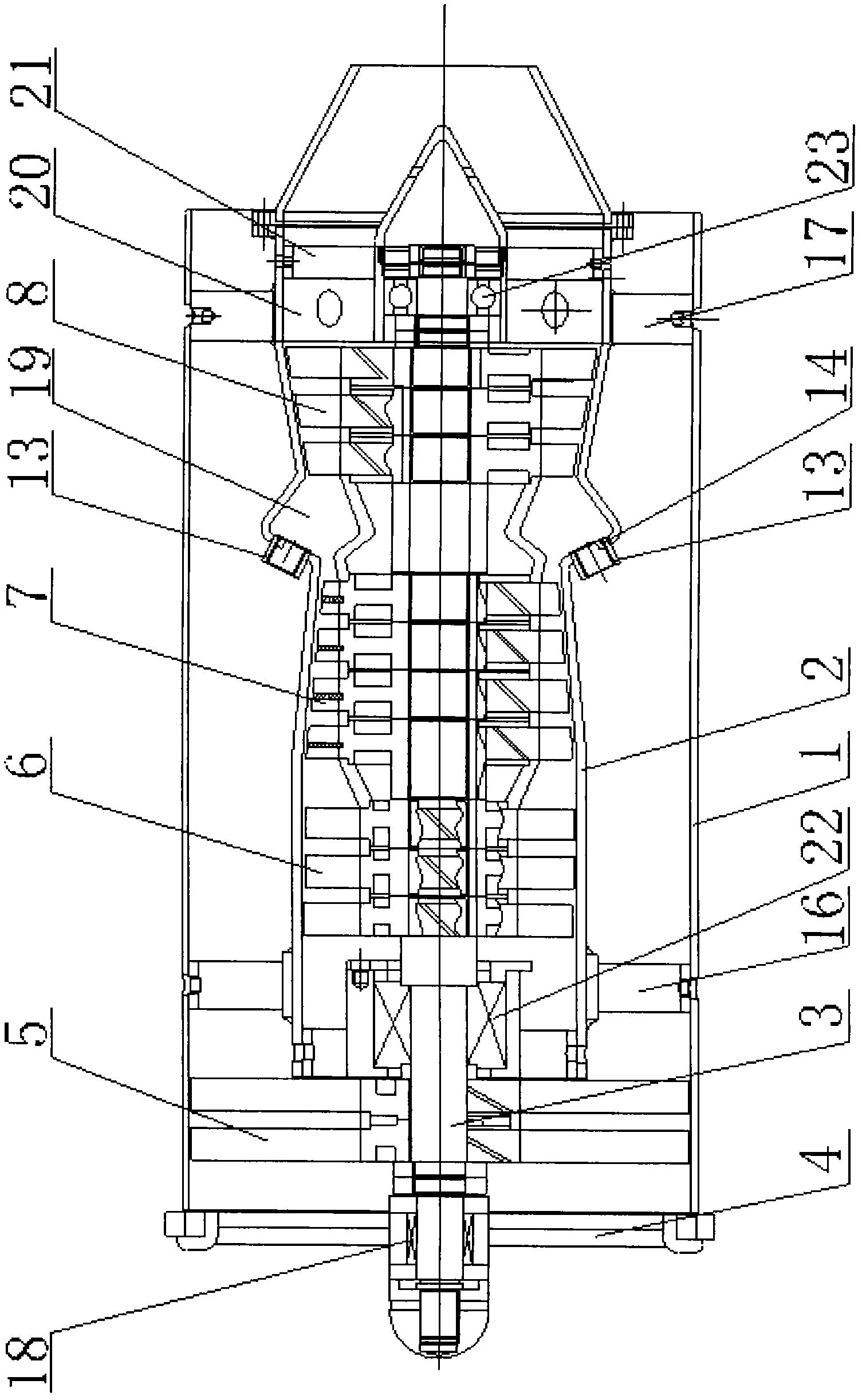

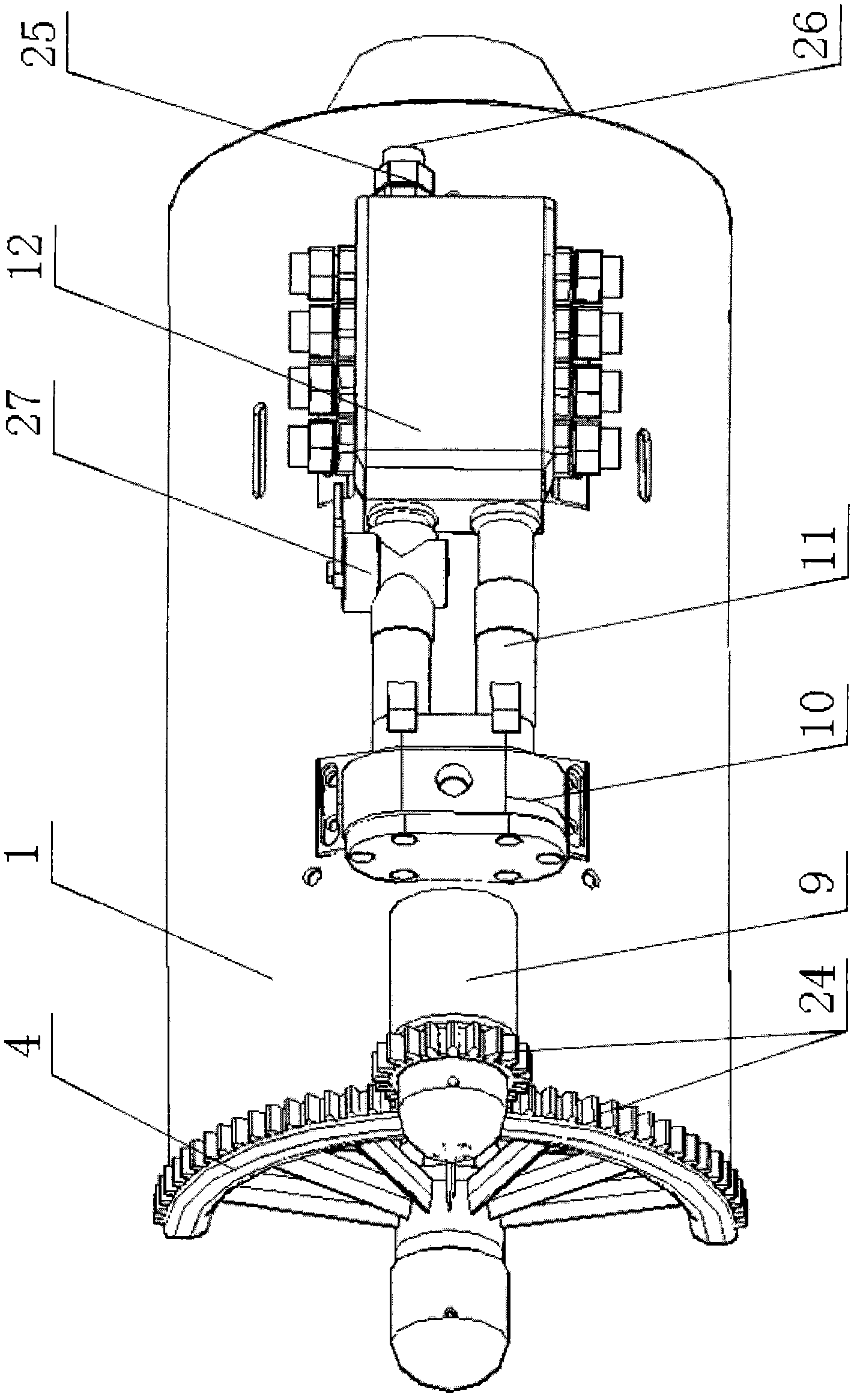

[0019] Please refer to the attached figure 1 And attached figure 2 Shown, the present invention is a kind of miniature turbofan engine, and it is made up of outer duct 1, interior duct 2, main shaft 3, inlet guide vane 4, fan 5, medium pressure compressor 6, high pressure compressor 7, turbine 8, The starter motor 9, the first oil distributor 10, the atomizing fuel injector 11, the second oil distributor 12, the fuel injector 13 and the spark plug 14 are assembled and formed.

[0020] Wherein, the inner duct 2 is installed in the outer duct 1 through a front bracket 16 of the outer duct and a rear bracket 17 of the outer duct.

[0021] The inlet guide vane 4 is located at one end of the outer duct 1 , and is mounted on the main shaft 3 through a one-way bearing 18 .

[0022] The fan 5, the medium-pressure compressor 6, the high-pressure compressor 7 and the turbine 8 are sequentially held on the main shaft 3 and rotated by the main shaft 3, and the holding method is specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com