Method for quenching underground coal gasifier

A technology for underground gasification and coal, applied in coal gasification, underground mining, construction, etc., can solve the problems of unfeasible, difficult access for firefighters, etc., and achieve the effect of easy implementation, simple operation, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

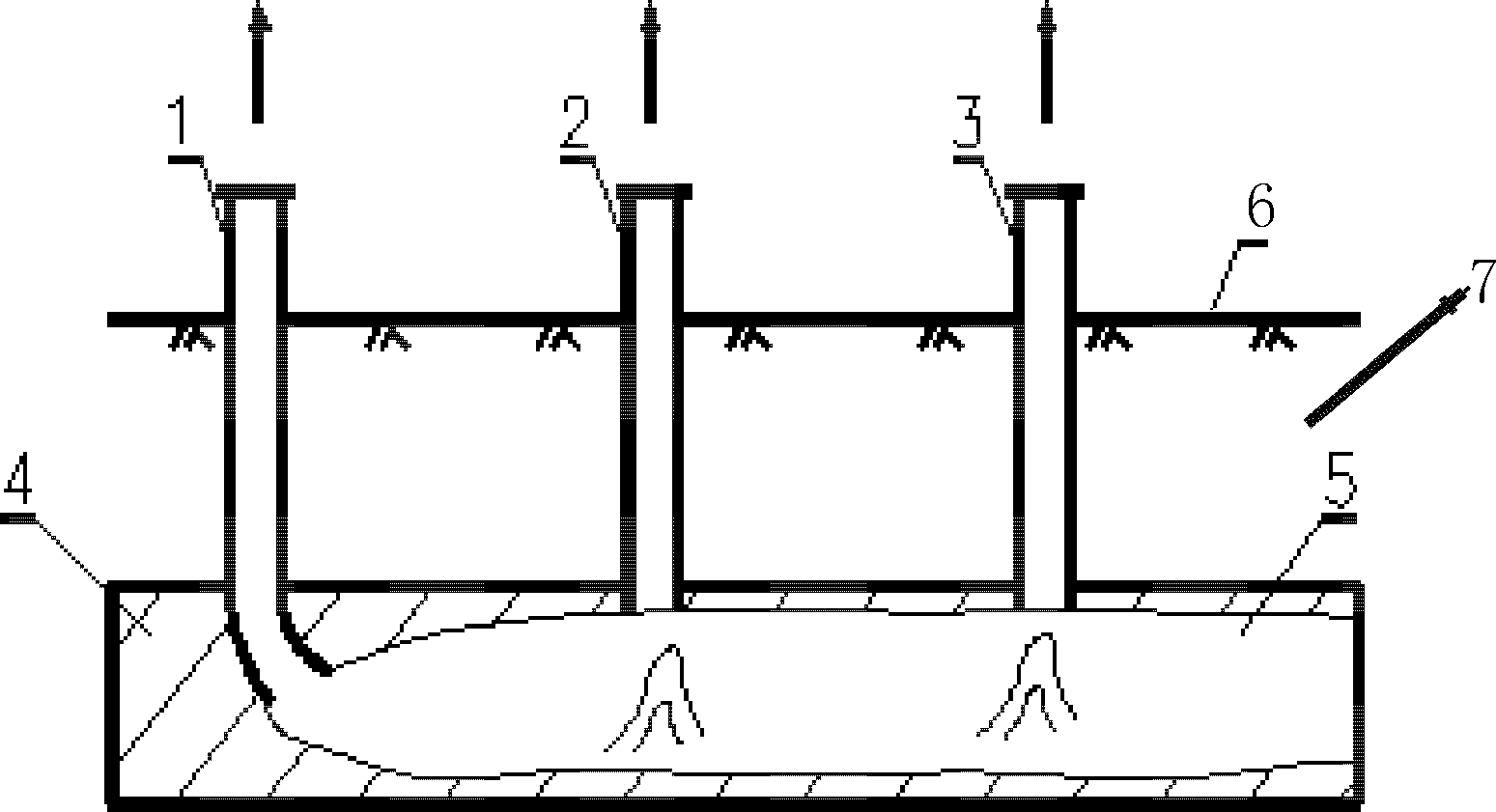

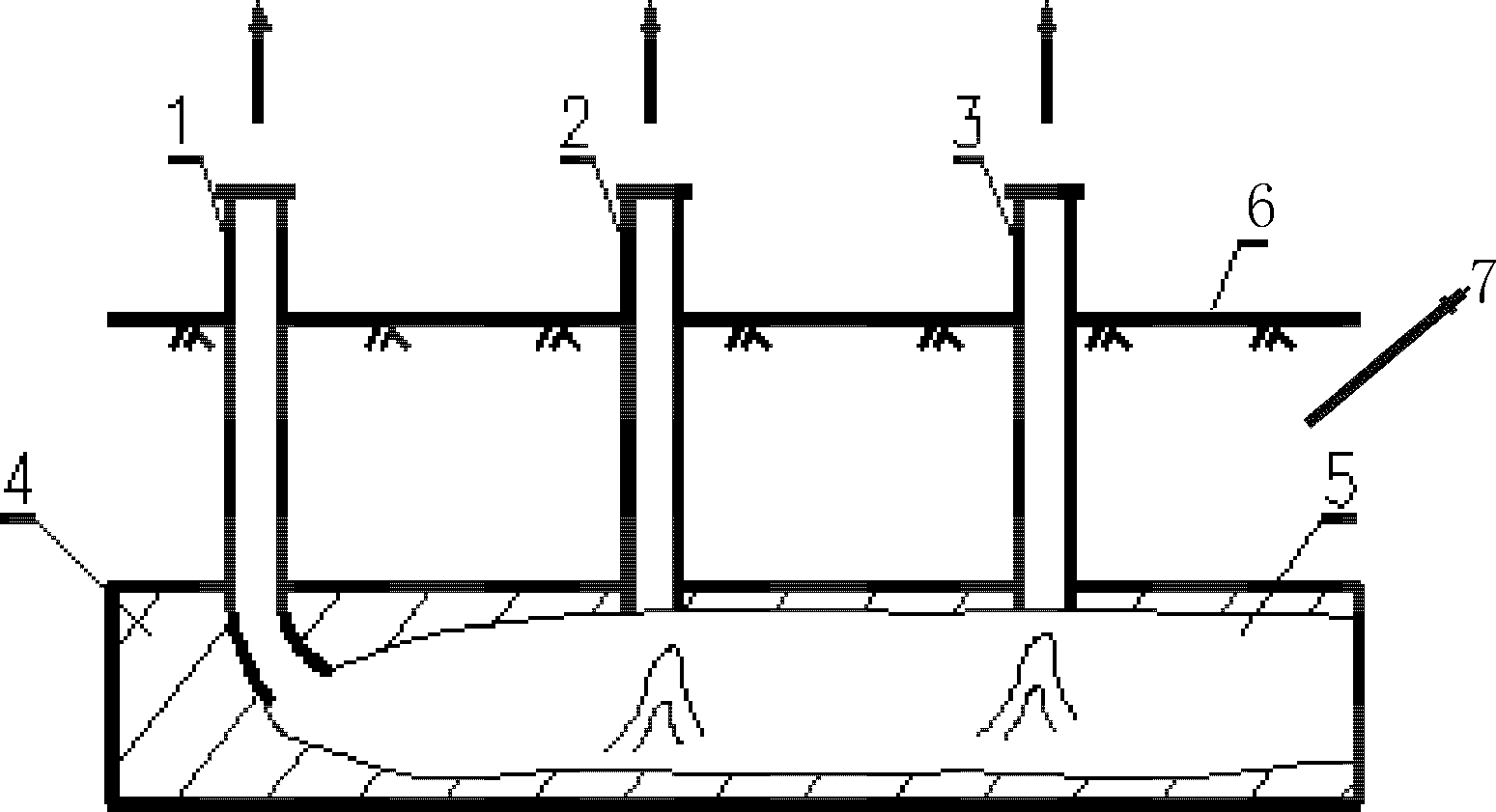

[0039] figure 1 A schematic diagram of an underground coal gasifier in which the method of the present invention may be implemented is shown. Such as figure 1 As shown, a typical underground coal gasifier includes a number of gas inlet and outlet boreholes 1, 2 and 3, a coal seam 4 and a burnout area 5 distributed at different positions in the gasifier area. The gas inlet and outlet boreholes 1 , 2 and 3 extend from the surface 6 into the coal seam 4 via the formation 7 . During the coal gasification process, borehole 1 is used as an air intake channel for introducing various gasification agents that promote coal seam combustion and gasification, and borehole 2 or 3 is used as a gas outlet channel for discharging coal seam combustion and gasification. gas products. The other of boreholes 2 or 3 may also be a passage for other purposes such as observation.

[0040] During the gasification process, the burn-out zone 5 gradually formed in the coal seam with the combustion of ...

Embodiment 2

[0048] The furnace extinguishing method of embodiment 2 is basically the same as embodiment 1, only difference is, in figure 1 During the shutdown process of the shown underground coal gasifier, the gas in the burn-out area 5 is extracted in turn through the three inlet and outlet holes 1, 2 and 3. Outside the gas pipeline, other pipelines are closed. This method can also achieve rapid and uniform negative pressure extraction, thereby enabling rapid shutdown.

[0049] other embodiments

[0050] Embodiments 1 and 2 illustrate the shutdown method of an underground coal gasifier according to the present invention by taking a specific gasifier as an example. However, the present invention is not limited to specific examples. For example, according to the modified implementation of embodiment 1 or 2, it is also possible to draw air through only one or two air inlet and outlet holes, and at the same time close other air inlet and outlet holes to form a negative pressure in the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com