Treatment system for tail gas generated during acid and water conversion in cold rolling acid-washing acid-regenerating process

A treatment system and acid regeneration technology, applied in the field of treatment systems, can solve the problems of polluting the environment, low HCL content, inability to absorb iron ions, etc., and achieve the effects of avoiding acid pollution, reducing water treatment costs, and avoiding crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

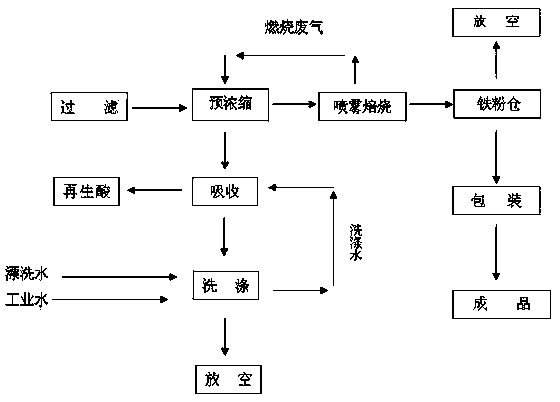

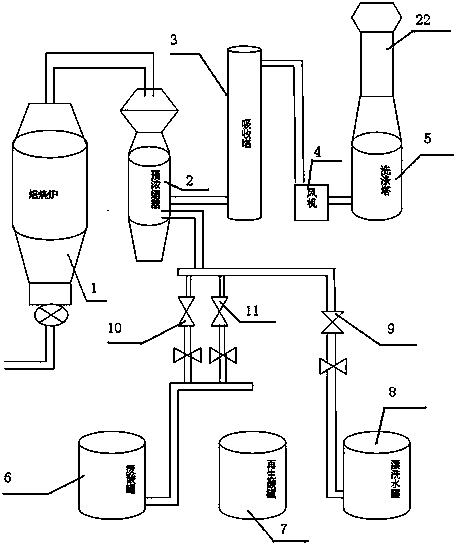

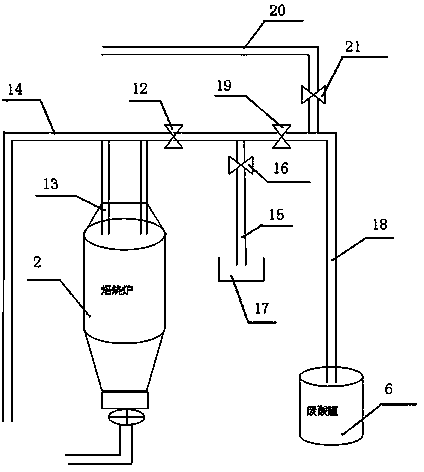

[0018] In the embodiment, a treatment system for generating tail gas by conversion of acid and water in the cold-rolled pickling acid regeneration process, including a roasting furnace 1, a pre-concentrator 2, an absorption tower 3, a fan 4, a washing tower 5, and a waste acid tank 6 , regeneration acid tank 7 and rinsing water tank 8, the pickling waste acid is roasted, dedusted, cooled and absorbed to regenerate free acid and obtain iron oxide powder at the same time; the cold-rolled pickling acid regeneration process is divided into four operation modes : Fresh water operation mode, rinse water operation mode, acid operation mode, water operation to acid operation or acid operation to water operation mode; between the pre-concentrator 2 and the rinse water tank 8 is provided with a rinse water regulating valve 9, the valve It can only be open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com