Ni-series low-temperature steel, manufacture method thereof, liquefied natural gas storage tank and ship body for transportation ship

A technology of liquefied natural gas and manufacturing method, applied in the field of liquefied natural gas storage tanks and hulls of liquefied natural gas transportation ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

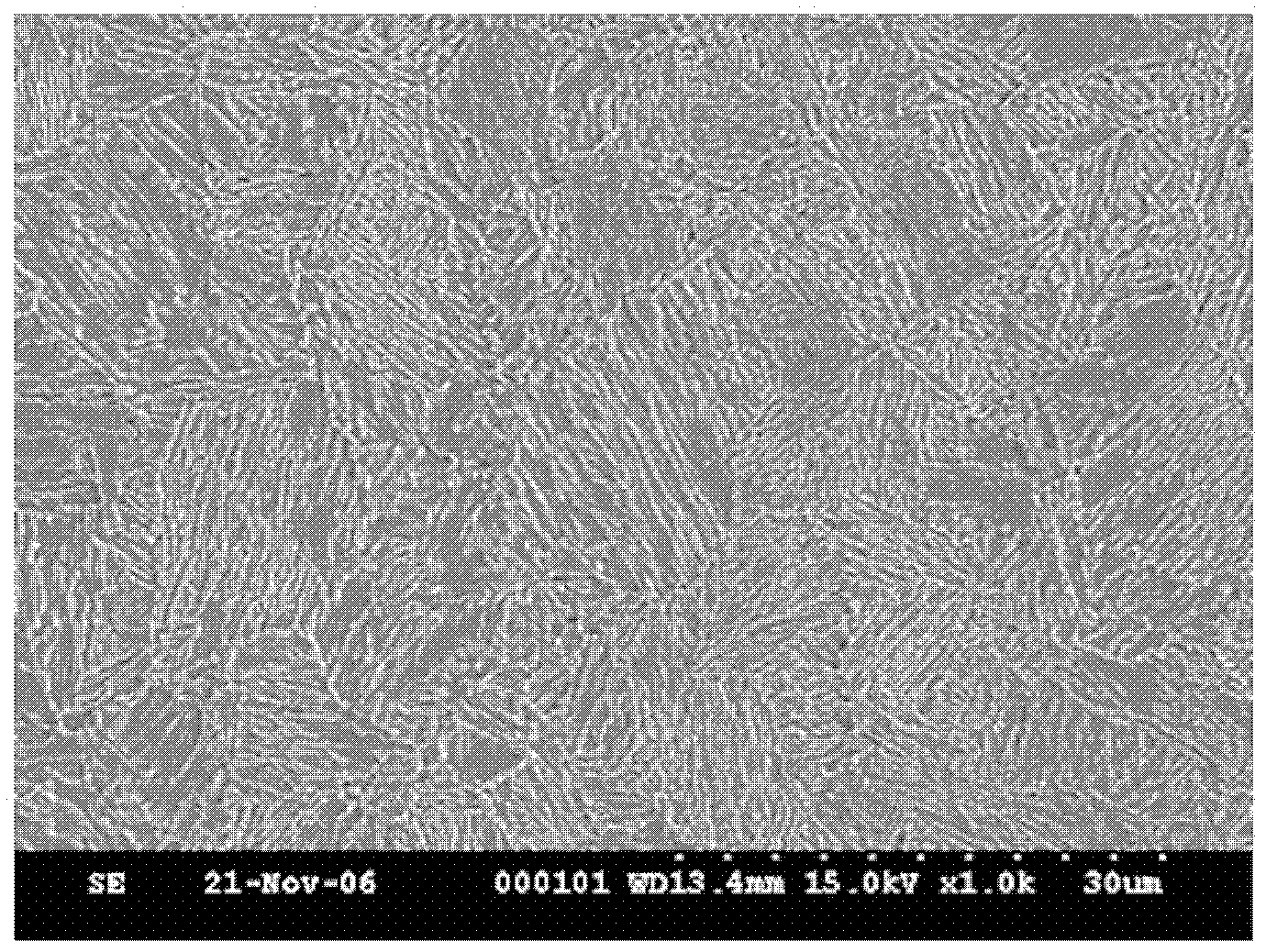

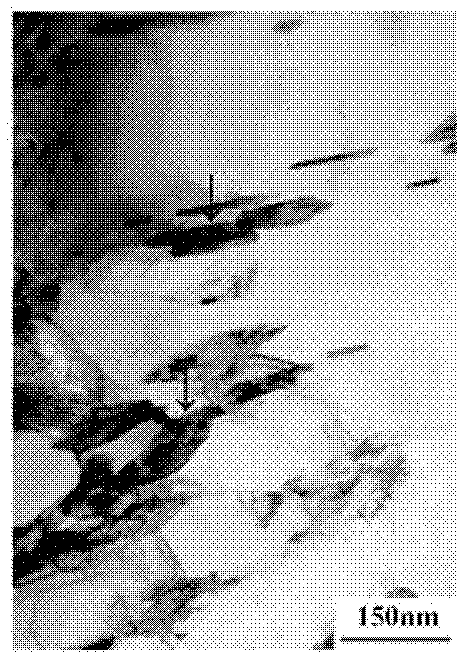

[0068] The chemical composition contained in the Ni-based low-temperature steel according to Example 1 is C: 0.057%, Si: 0.16%, Mn: 0.72%, P: 0.0023%, S: 0.0011%, Ni: 8.94%, Al: 0.022%, Cu: 0.013%, Mo: 0.003%, Ti: 0.012%, O: 0.0012%, N: 0.0043%, Ca: 0.0012%, and the balance is Fe. The Ni-based low-temperature steel plate is prepared by using the manufacturing method of the Ni-based low-temperature steel according to the present invention.

Embodiment 2

[0070] The chemical composition contained in the Ni-based low-temperature steel according to Example 2 is C: 0.049%, Si: 0.14%, Mn: 0.73%, P: 0.0028%, S: 0.0010%, Ni: 9.08%, Al: 0.031%, Cu: 0.08%, Mo: 0.002%, Ti: 0.011%, O: 0.0009%, N: 0.0037%, Ca: 0.0008%, and the balance is Fe. The Ni-based low-temperature steel plate is prepared by using the manufacturing method of the Ni-based low-temperature steel according to the present invention.

Embodiment 3

[0072] The chemical composition contained in the Ni-based low-temperature steel according to Example 3 is C: 0.054%, Si: 0.18%, Mn: 0.70%, P: 0.0034%, S: 0.0024%, Ni: 9.25%, Al: 0.013%, Cu: 0.57%, Mo: 0.001%, Ti: 0.023%, O: 0.0014%, N: 0.0054%, Ca: 0.0022%, and the balance is Fe. The Ni-based low-temperature steel plate is prepared by using the manufacturing method of the Ni-based low-temperature steel according to the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com