Preparation method of molasses for recycling

The technology of molasses and inoculum is applied in the preparation field of comprehensive utilization of molasses, and can solve the problems of increased ash and colloidal substances, decreased fermentable sugar, serious problems, etc., so as to improve production efficiency and labor productivity, improve bacterial protein content, The effect of enhancing the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

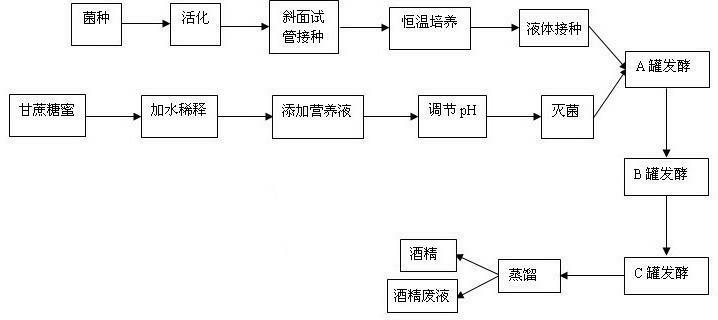

[0029] A kind of preparation method of molasses comprehensive utilization described in the embodiment of the present invention 1, this preparation method comprises the following steps:

[0030] (1) Prepare the medium, prepare the molasses culture medium A tank, B tank and C tank, and prepare the yeast fermentation inoculum at the same time;

[0031] (2) Fermentation is carried out, and the fermentation is divided into three stages, such as figure 1 As shown, they are:

[0032] The first stage: Inoculate Saccharomyces cerevisiae into 20°-35°Brix (Bx) molasses culture solution A tank, ferment at 30°C-35°C and pH4.5-5.5, the inoculation amount is 5%- 10%, when the residual sugar content is lower than 15°-20°Brix (Bx), the alcohol concentration reaches 8%-10%, and enters the second fermentation stage;

[0033] The second stage: the first-stage reaction solution is introduced into the molasses culture medium B tank, inoculated with fission yeast and Aspergillus oryzae, the inocul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com